Automotive glass clamping strip bending device and forming method thereof

A bending device and technology for automotive glass, which is applied in the field of automotive glass strip bending device and its processing and forming, can solve the problems of large number of molds, numerous processes, high cost, etc., and achieve the effect of reducing the number of molds, reducing product costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

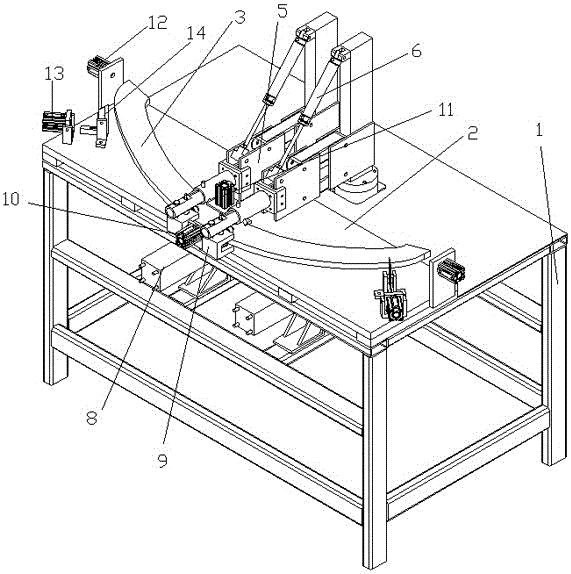

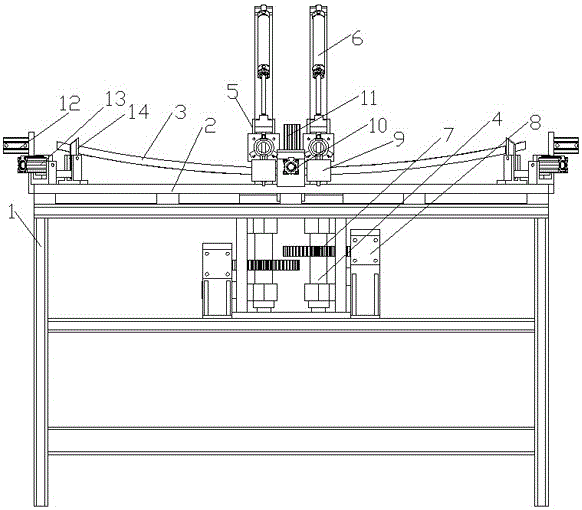

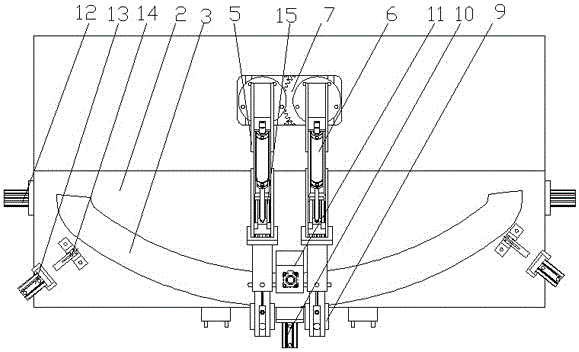

[0021] Such as Figure 1-5 As shown, a device for bending automotive glass strips includes a frame 1, a workbench 2 is arranged on the front side of the upper side of the frame 1, and a bending mold 3 and an end compression cylinder 12 are arranged on the workbench 2. , the front side of the bending mold 3 is arc-shaped and matches the shape that the clip 21 needs to be bent and formed. It must bounce back, so the arc of the bending mold 3 is generally larger than the arc that the bar 21 needs to be bent and formed. Two rotating shafts 4 that turn to the opposite direction are arranged symmetrically on the rear side of the upper side of the frame 1. The lower half of the rotating shaft 4 is provided with The gear 7 and the rotating shaft 4 are rotatably connected with the frame 1, the frame 1 is provided with an oil cylinder 8, the end of the piston rod of the oil cylinder 8 is provided with a rack 16 meshing with the gear 7, and the upper part of the rotating shaft 4 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com