Bolt component pressfit riveting machine

A bolt assembly and riveting machine technology, which is applied in the field of press-fitting machines, can solve problems such as slowing down production efficiency, and achieve the effects of saving turnaround time, speeding up assembly speed, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

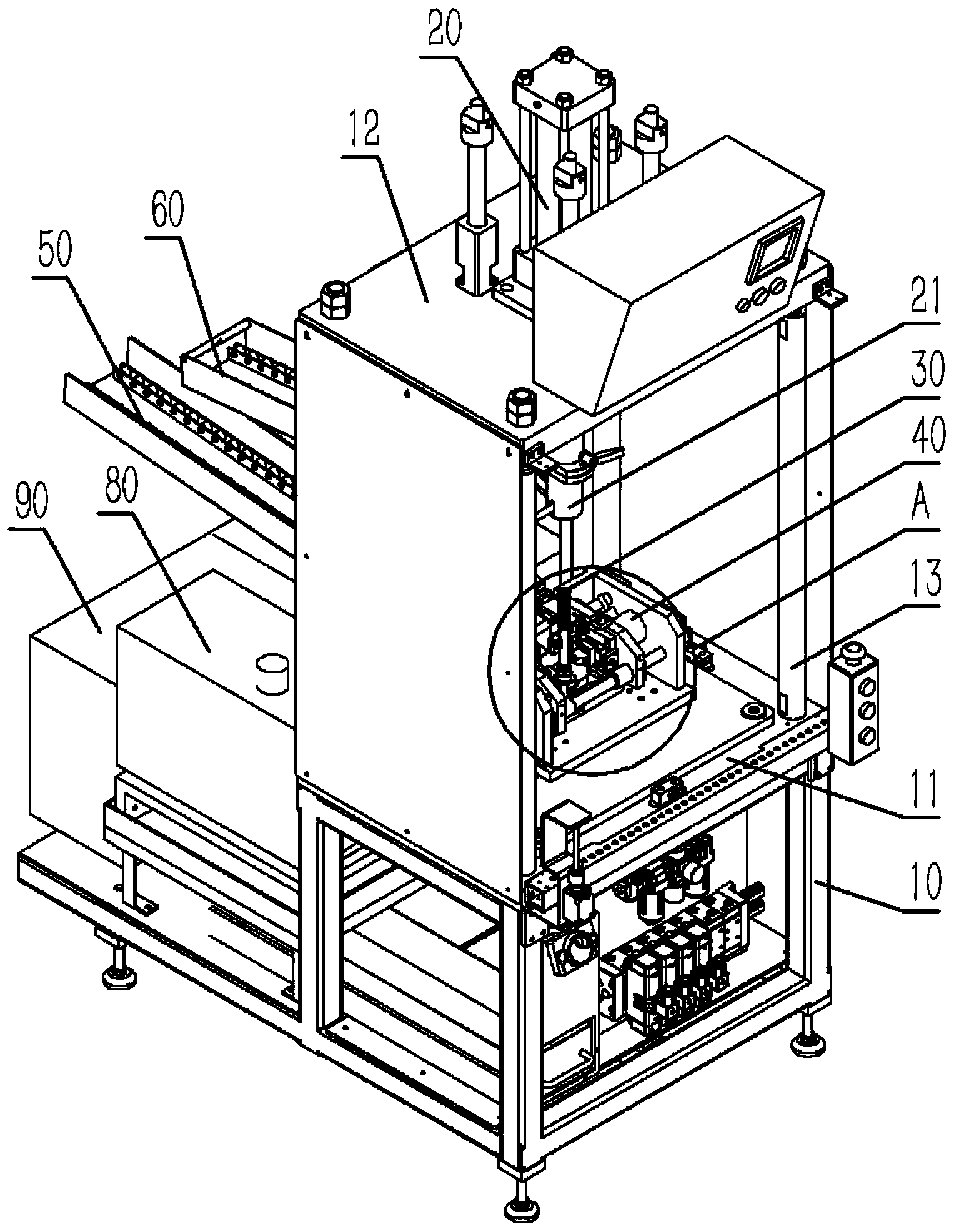

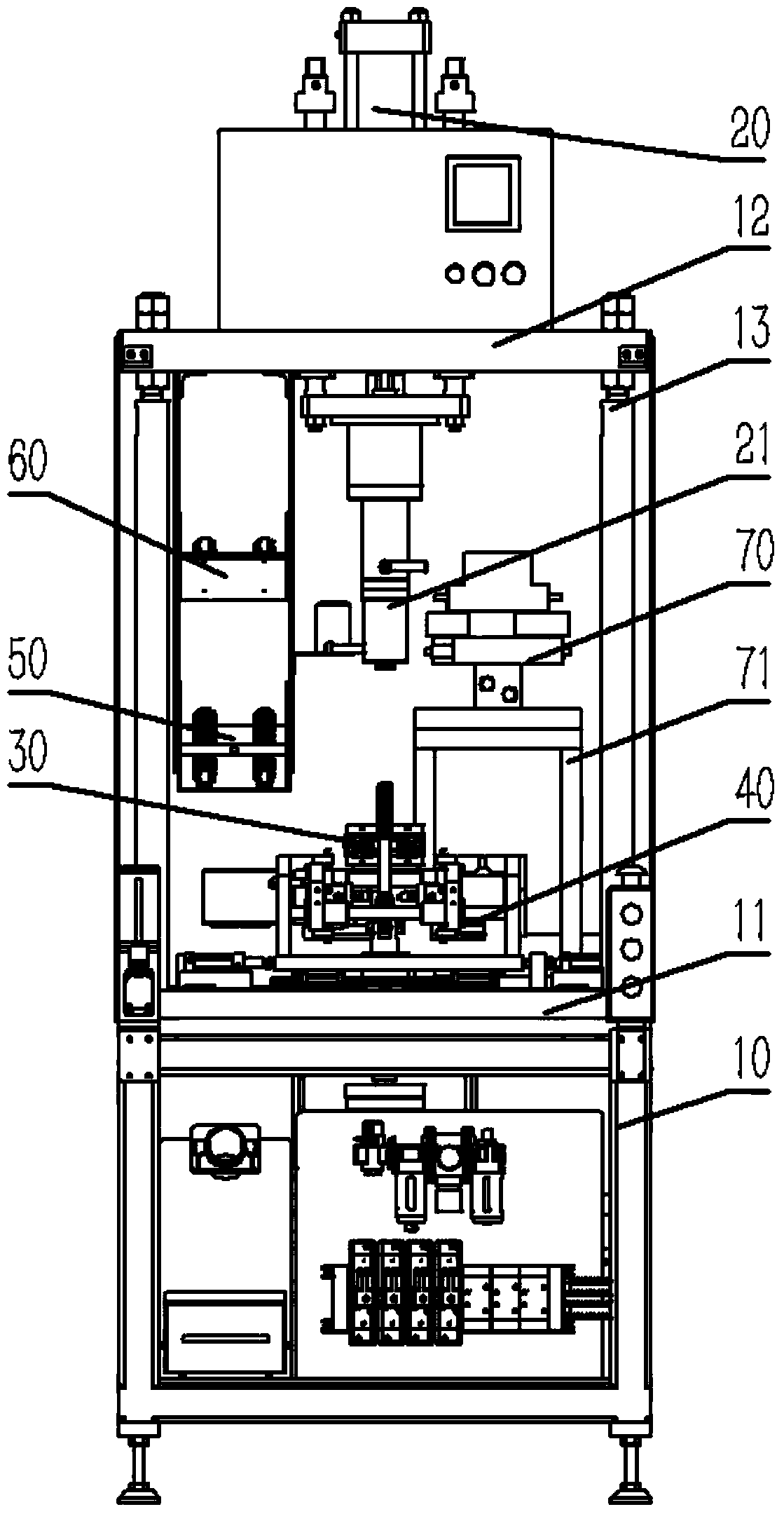

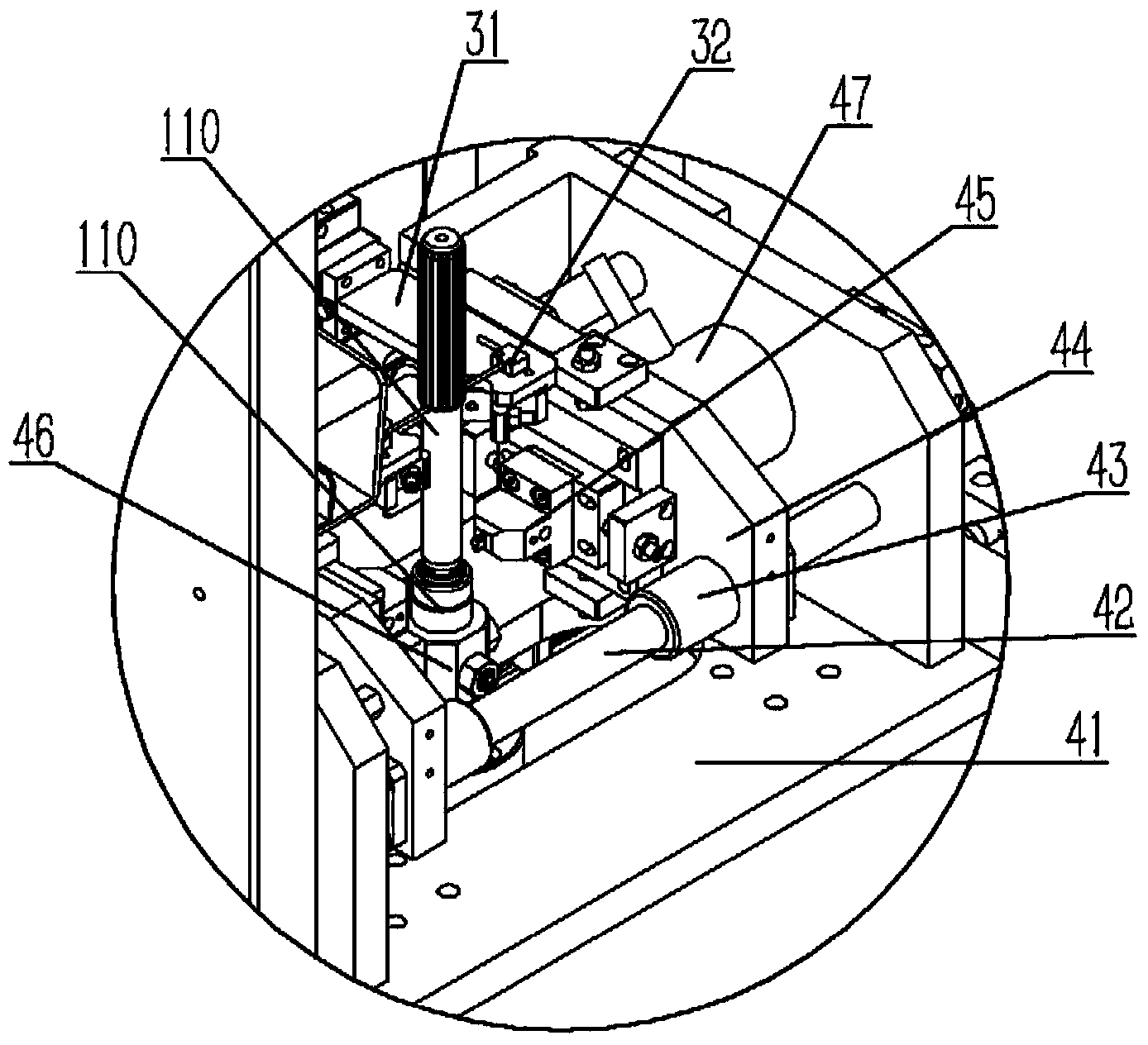

[0018] Example: see Figure 1 to Figure 4 As shown, the bolt assembly is pressed into the riveting machine, including a frame 10. A workbench 11 is provided on the frame 10. Four sets of pillars 13 are fixed on the workbench 11. Top plates 12 are fixed on the tops of the four sets of pillars 13. On the top plate 12 An oil cylinder 20 is fixed, and a press fitting head 21 is fixed on the piston rod of the oil cylinder 20. A riveting mechanism 40 is fixed on the workbench 11 below the pressing head 21. A clamping mechanism 30 is arranged above the riveting mechanism 40. The clamping mechanism 30 Fixed on the frame 10; the frame 10 on the right side of the riveting mechanism 40 is fixed with a feed slide 50 inclined forward and downward, and the top of the feed slide 50 is provided with a waste slide 60 inclined forward and upward, and the waste The slideway 60 is fixed on the frame; a hydraulic valve fixing bracket 71 is fixed on the workbench 11 on the left side of the riveting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com