Process for processing external threads of thin-wall threaded sleeve and threaded sleeve turning clamp used for same

A processing technology and external thread technology, which is applied in the field of thin-walled parts processing, can solve the problems of high material waste rate, unqualified products, and scrapped products, and achieve the effects of improving processing efficiency, saving blank materials, and stable processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

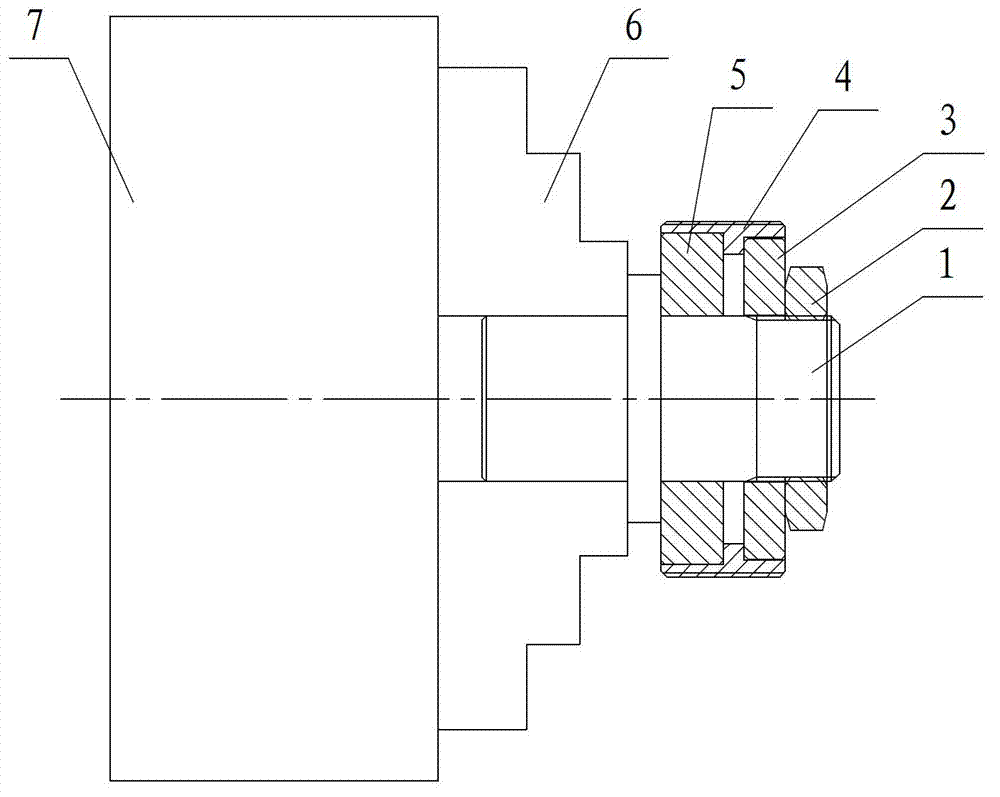

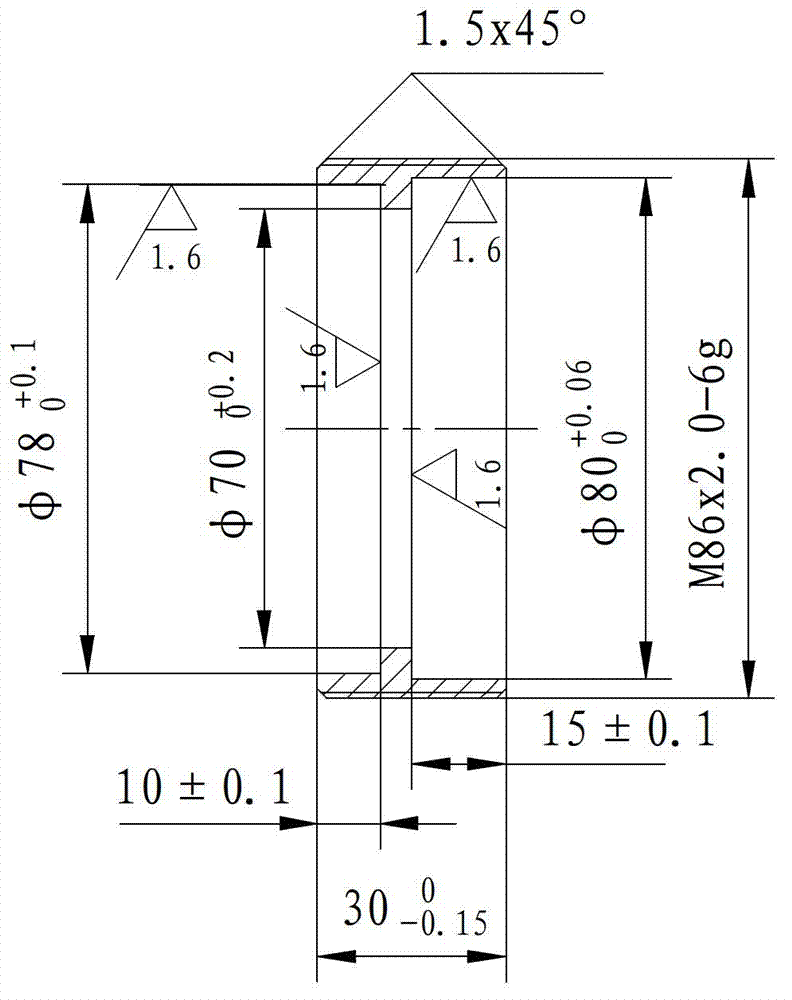

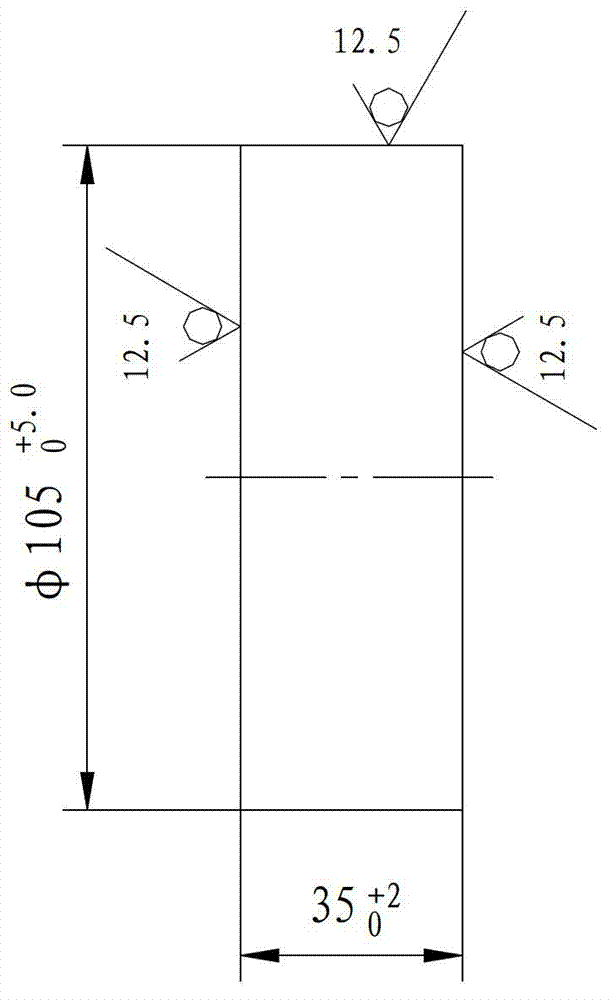

[0031] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0032] The processing technology of the external thread of the thin-walled screw sleeve includes the following steps:

[0033] (1) Rough car:

[0034] a. The outer circle of the clamping screw sleeve forging, the rough turning end face and the outer circle;

[0035] b. Turn around, clamp the outer circle on the other side, turn the end face, and the outer circle to ensure the total length requirements;

[0036] c. Drill and roughly bore the stepped holes on both sides;

[0037] d. Remove the outer circle connection knife marks;

[0038] (2) Positioning holes in the finish car:

[0039] a. Clamp the outer circle, take one end face as the reference, flatten the other end face, and finely bore the stepped hole on one side to the required size;

[0040] b. Turn around, clamp the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com