Production method for water chamber head of nuclear power equipment

A technology of a water chamber head and a manufacturing method, which is applied in the field of the manufacture of water chamber heads of nuclear power equipment, can solve the problems of large manpower, material resources, low precision, poor repeatability of positioning, etc., and achieves reduction of production cycle and turnover. time and the effect of ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

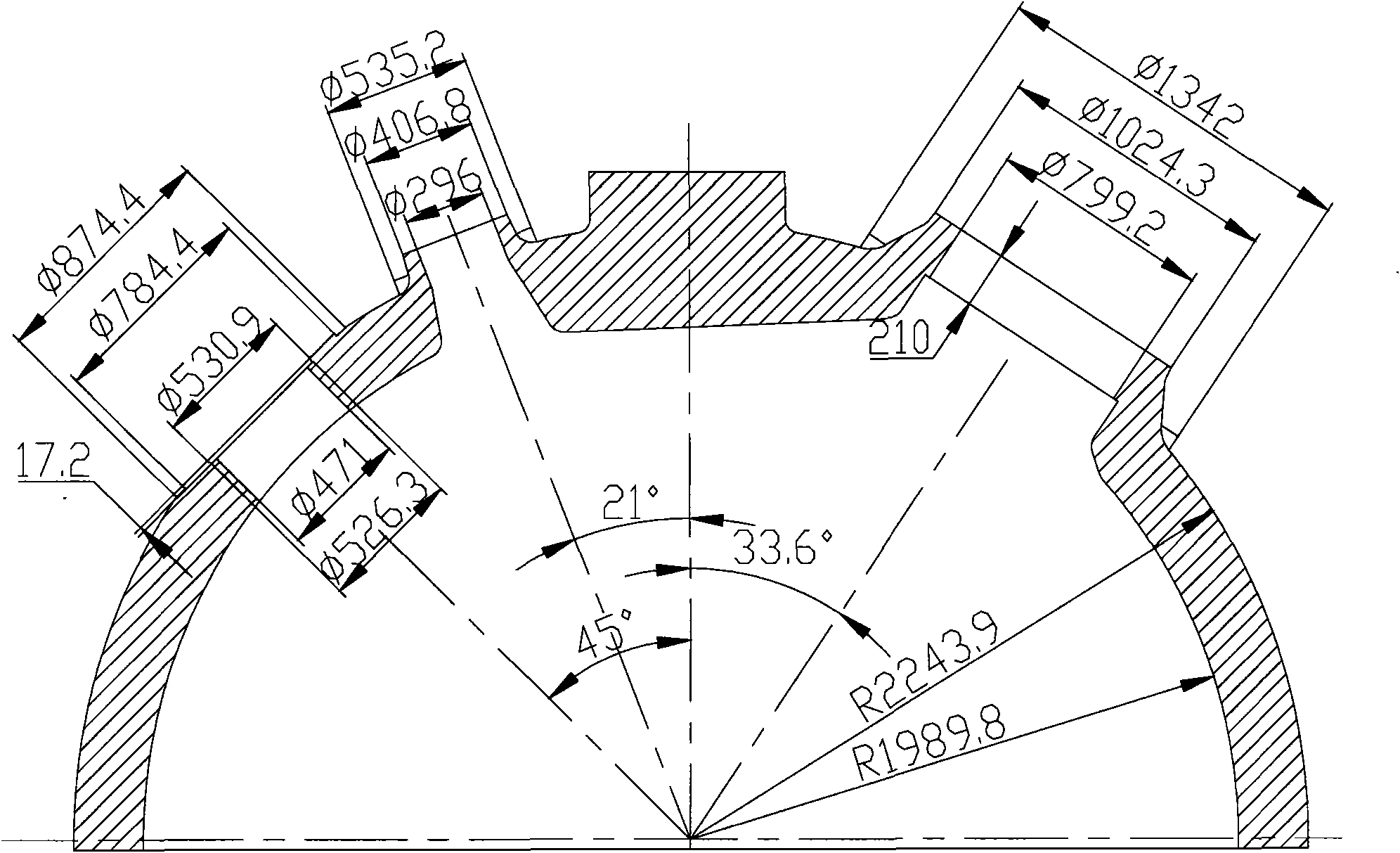

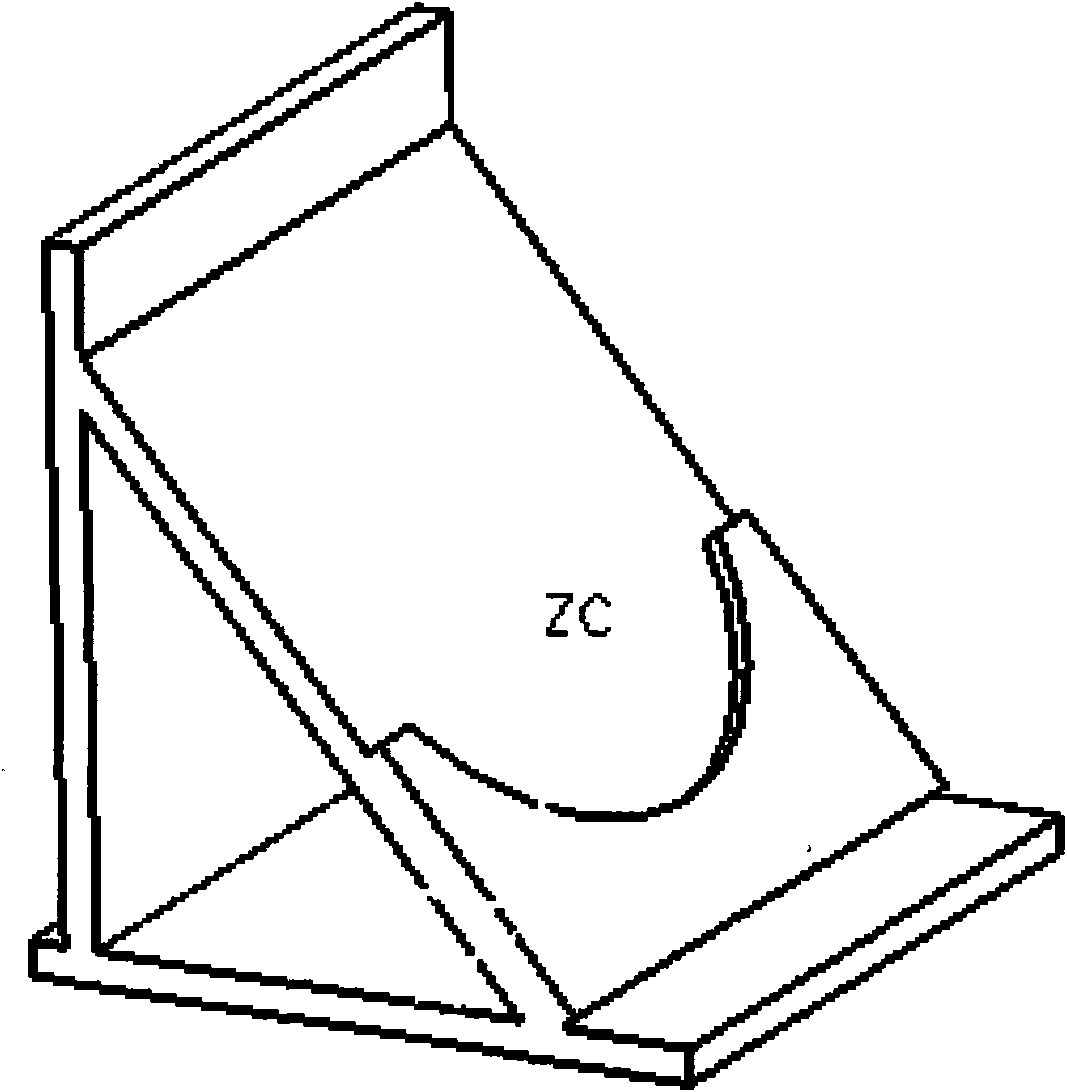

[0054] The manufacture method of the nuclear power equipment water chamber head of the present invention adopts such as Figure 4 The numerically controlled positioner shown is used in conjunction with the numerically controlled boring and milling machine to profile and mill the head of the water chamber.

[0055] The present invention adopts the following steps to process a cylindrical blank workpiece into a water chamber head with four inclined nozzles:

[0056] 1. Scribing: Draw the contour line and center cross line of the entire workpiece on the end surface of the workpiece, and lead the center line and nozzle center line to the outer cylindrical surface;

[0057] 2. Rough machining: the workpiece is clamped on the table top of the CNC positioner workbench 10, and a CNC boring and milling machine with a spindle of Φ200 is used for rough machining;

[0058] 1) Clamp the workpiece; turn the table top of the CNC positioner workbench 10 to a horizontal position so that the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com