Manufacturing method of metal frame for flat panel display

A flat panel display, metal frame technology, applied in metal processing equipment and other directions, can solve the problems of large stamping equipment and stamping die investment costs, low utilization of raw materials, aggravated production costs, etc., to reduce transportation costs, reduce production costs, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

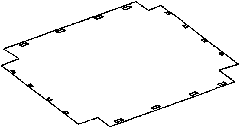

[0027] 2a to 2e are schematic diagrams of a method of manufacturing a metal frame according to an embodiment of the present invention. The metal frame for the flat panel display of the present invention only uses one to two punching machines and two to four sets of continuous punching dies. The manufacturing process is as follows:

[0028] Such as Figure 2a-1 , 2a-2 , 3a, 3b, first send the metal raw material (coil or plate) into the mold on the punching machine, and then punch out the pre-designed through holes, protrusions, and tenons on the raw material;

[0029] Such as Figure 2b-1 , 2b-2 As shown, the stamping machine is then used to continuously stamp the metal raw materials into a group of two "|"-shaped and "["-shaped blanks. In this step, the stamping machine must also be in the "|"-shaped and "[" The blanks reserved for the next step of folding are punched out on the blanks of the shaped blanks;

[0030] Such as Figure 2c-1 , 2c-2 As shown, the punching machine then ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com