Reinforcing steel formwork supporting rack for thin-walled hollow high pier and construction method

A technology for steel support and formwork, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of difficult to control the thickness of the protective layer, complicated erection process of the support, and high erection cost. It is easy to achieve verticality and stability. The effect of shortening the construction period and ensuring the construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

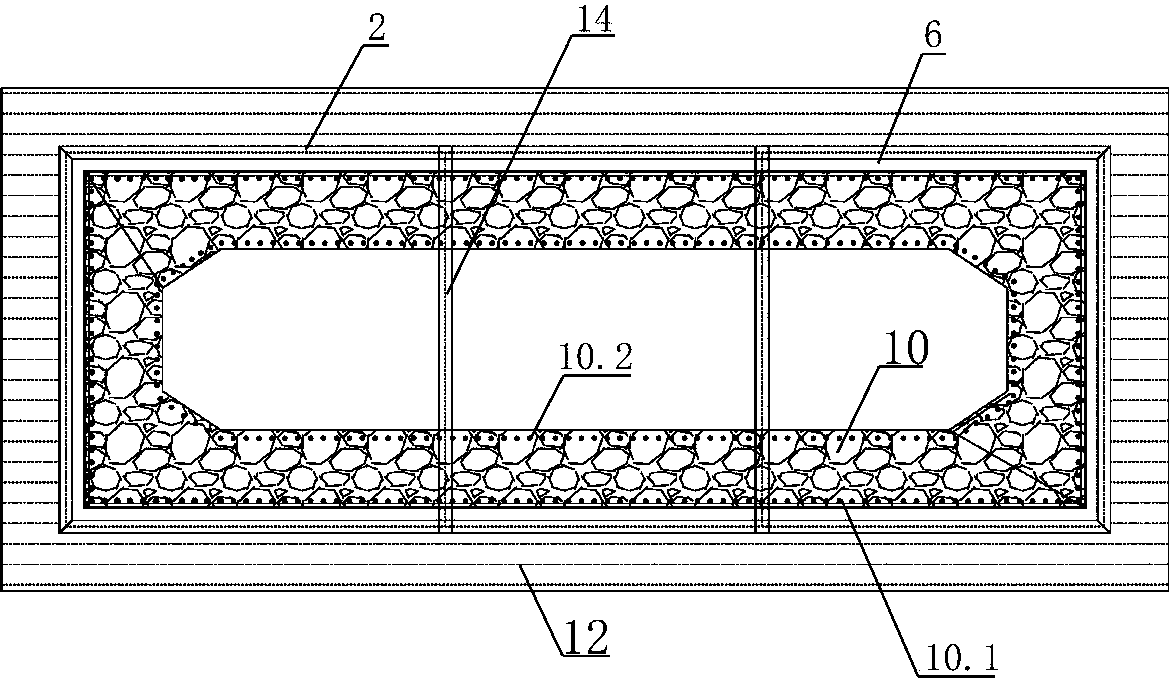

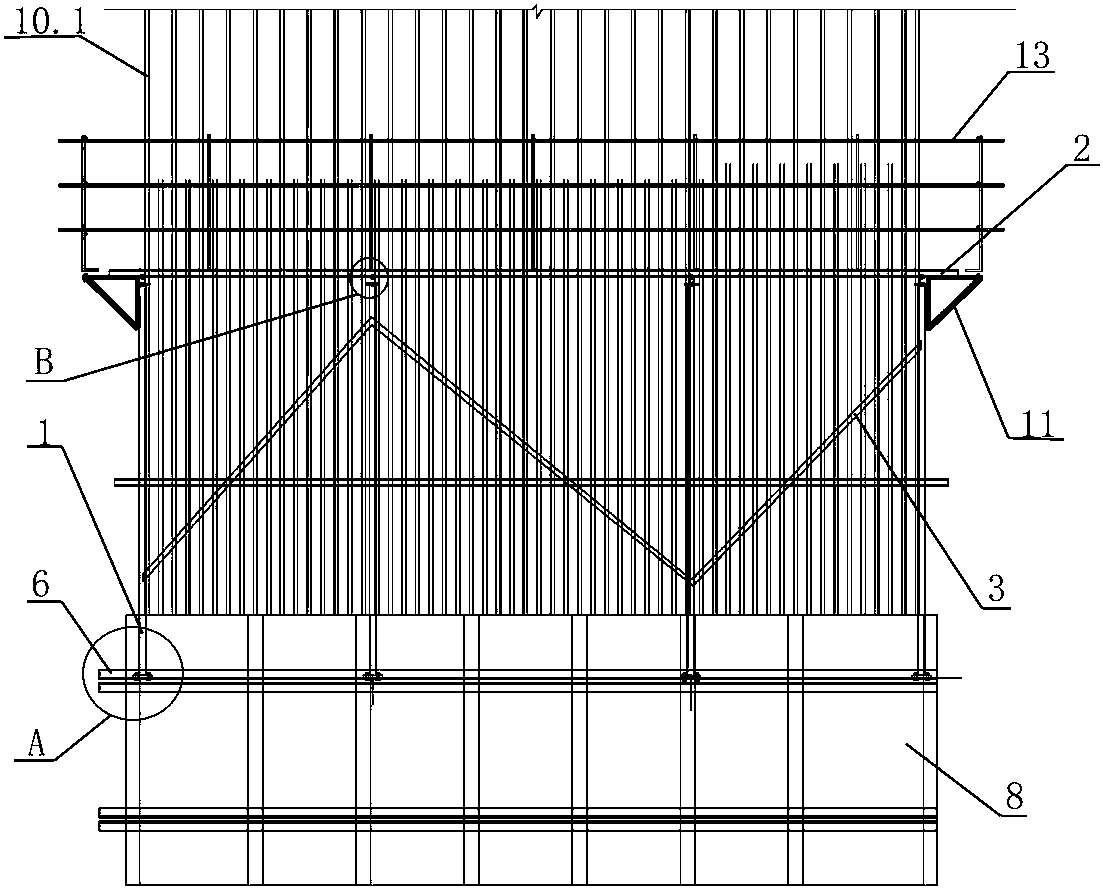

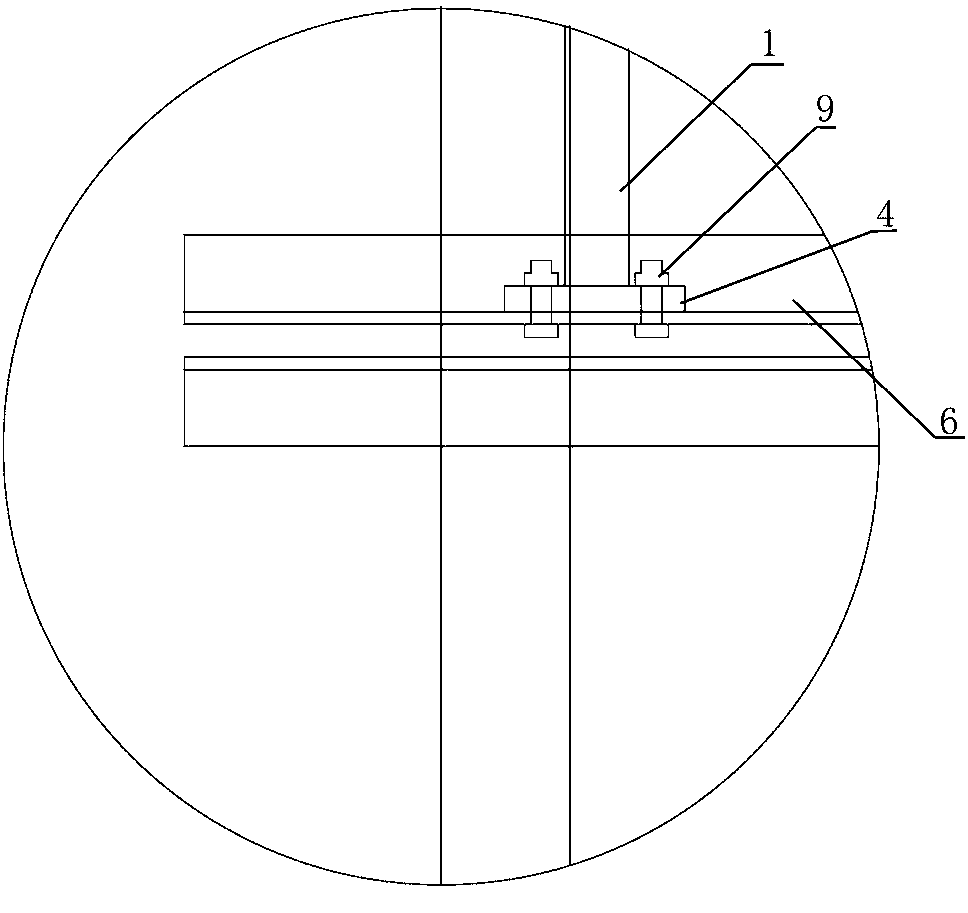

[0039] Examples see Figure 1 to Figure 10 As shown, a thin-walled hollow high pier reinforced formwork frame is arranged on the outer periphery of the thin-walled hollow high pier 10 to be constructed, and includes a steel bar formwork skeleton and an operating platform. The horizontal bar 2 and the vertical bridge are composed of a horizontal bar 14; the bottom end of the vertical bar 1 is provided with a Falun disc 4, and the bottom end of the vertical bar 1 is welded to the Falun disc 4, and the Falun disc 4 is connected to the shaped disc by bolts 9. The overturned purlin 6 of the steel formwork 8 is fixedly connected, the top of the vertical bar 1 is welded with a connecting steel plate 7, and the connecting steel plate 7 is connected to the top longitudinal bridge to the cross bar 14 through bolts 9, and the horizontal bridge to the cross bar 2 The vertical longitudinal bridge is erected on its top surface to the cross bar 14 and connected by bolts.

[0040] The operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com