Assembled overhanging support frame

A prefabricated and overhanging technology, applied in the direction of scaffolding, building structure support, building structure support, etc., can solve the problems of short length and complicated things, and achieve low cost, wide application range and strong promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

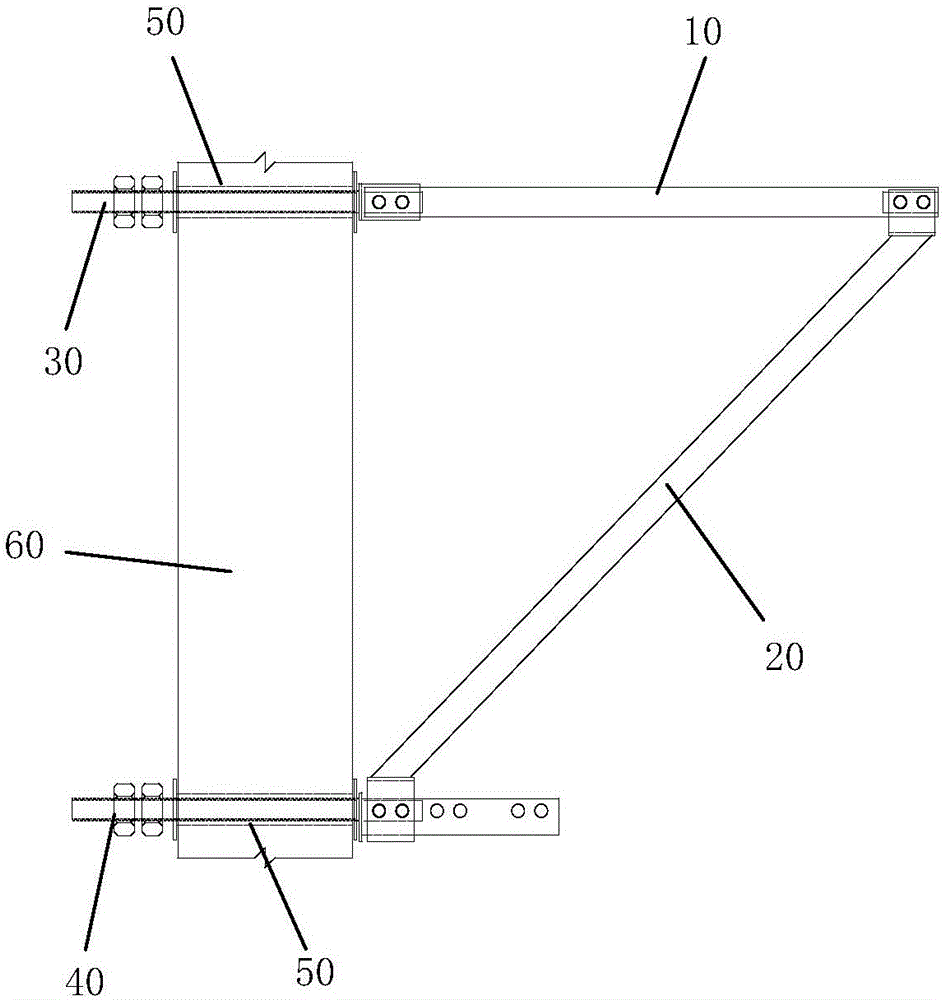

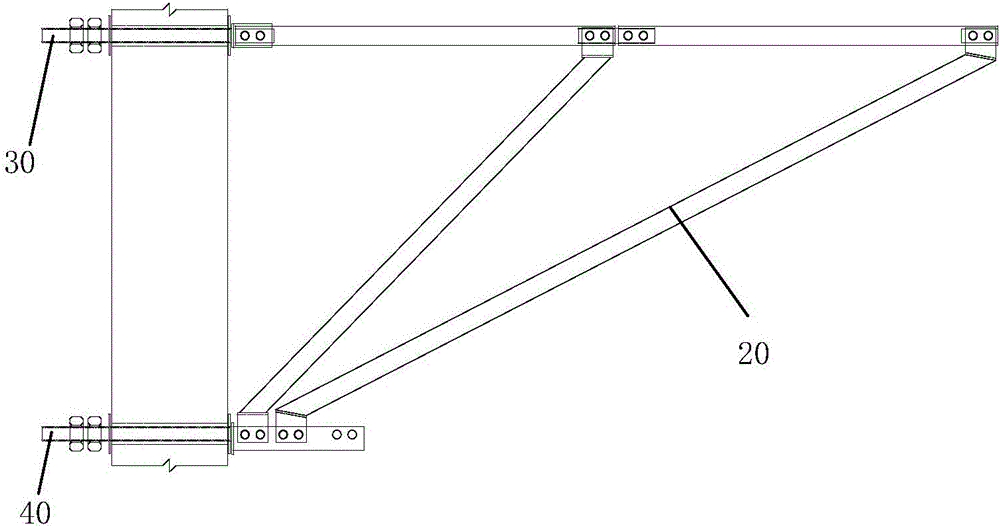

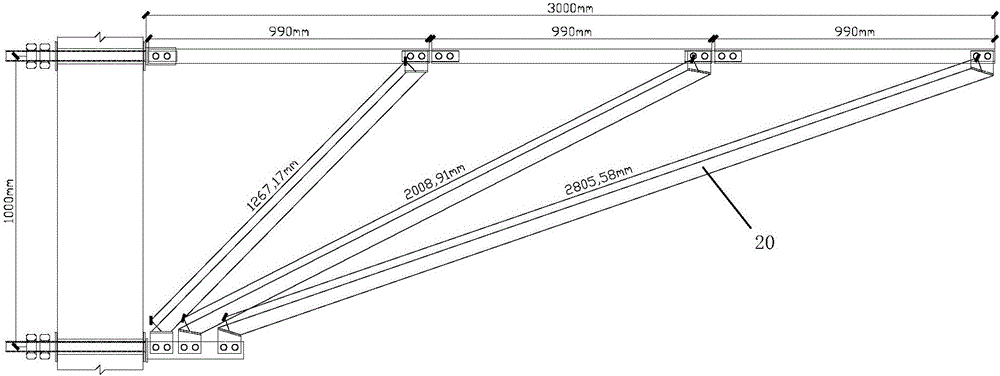

[0028] refer to Figure 1 to Figure 3 , in this preferred embodiment, an assembled cantilever bracket includes a plurality of horizontal rods 10, a diagonal brace 20 for supporting the horizontal rods 10, and an upper attachment 30 and a lower attachment for being installed on the attachment 60 pieces 40, of which,

[0029] A plurality of horizontal rods 10 are detachably connected from head to tail in turn, and the horizontal rod 10 at the head end is detachably connected to the upper attachment 30. Each horizontal rod 10 is correspondingly provided with a diagonal strut 20, and the two ends of the diagonal strut 20 are respectively connected to the horizontal The rod 10 and the lower attachment 40 are detachably connected.

[0030] Further, refer to Figure 1 to Figure 3 , the assembled cantilever bracket also in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com