Novel PCB (printed circuit board) antistatic turnover box

An anti-static, turnover box technology, applied in the field of electronics, can solve the problems of large investment regardless of cost, inconvenient handling, occupying a large space, etc., to achieve the effect of low labor intensity, convenient turnover, and elimination of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

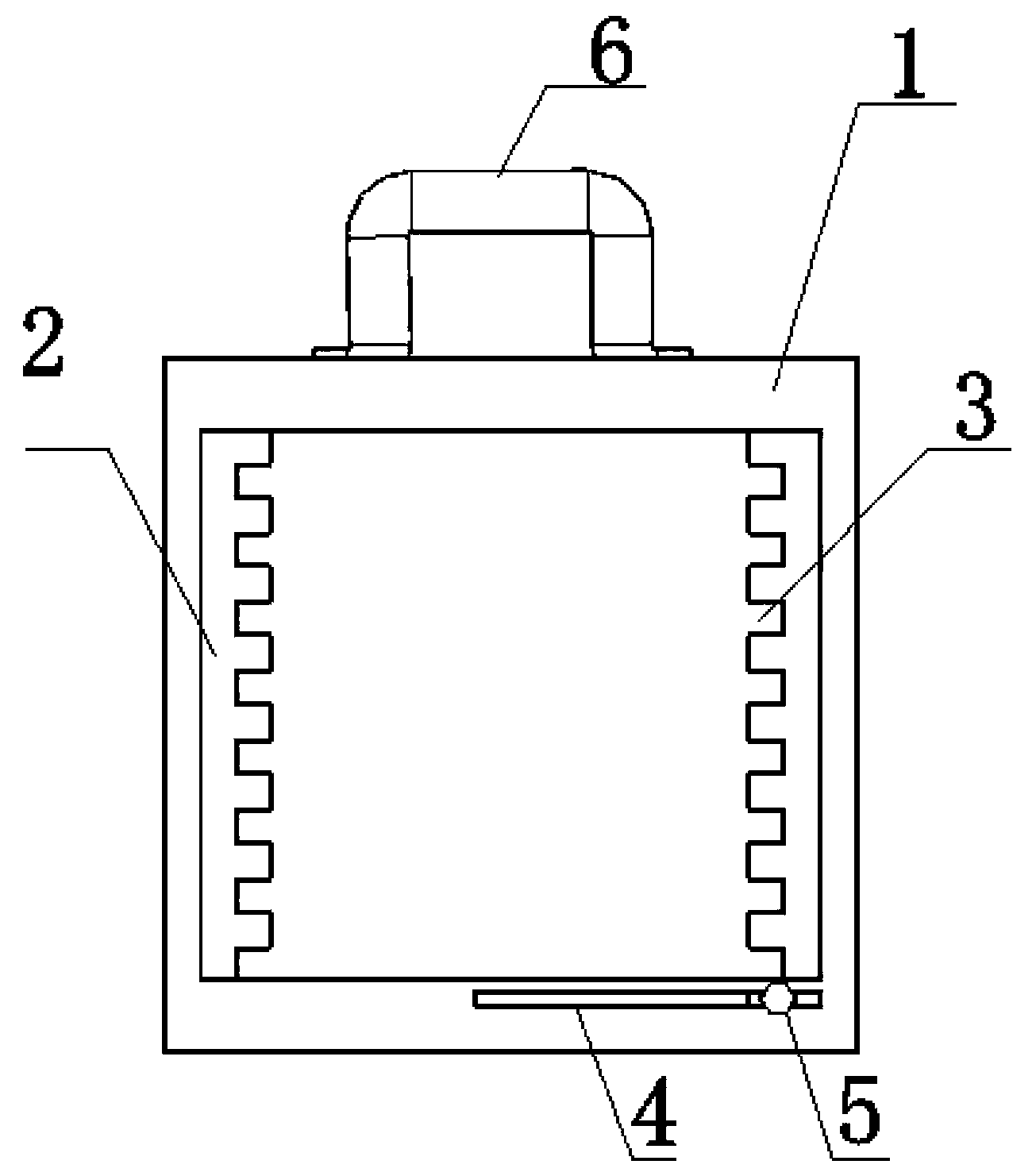

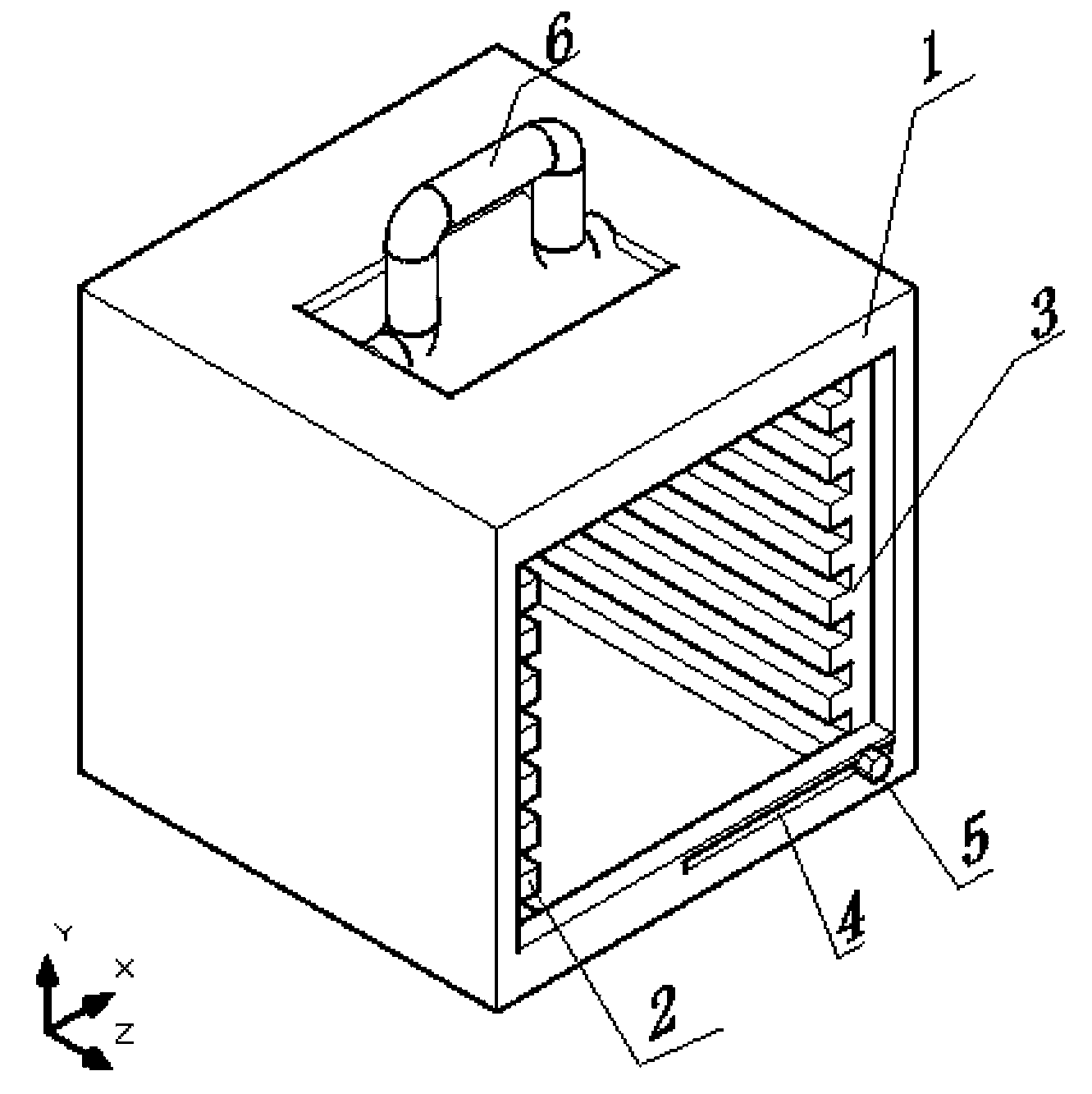

[0012] Such as Figure 1 to Figure 2 As shown, a new type of PCB anti-static turnover box is composed of a box body 1, a handle 6 on the top of the box body 1, a guide rail 4 on the side of the box shell, and side panels 2 located on opposite sides of the box body 1; There are guide grooves 3 which are parallel and equidistant to each other, and nuts 5 pass through guide rails 4 to fix the movable side plates 2 . Two side plates 2 are fixed one and the other is movable, and its material is antistatic plastics. Its movable side plate is regulated by guide rail 4 by nut 5 on two opposite corners of side plate 2 .

[0013] Take PCB board turnover as an example, insert the PCB board into the guide grooves 3 of the two side panels at a time, and ensure that the PCB boards are placed in parallel, and when the turnover box is filled with PCB boards, you can manually hold the handle on the top of the box 6. Transport the turnover box to the designated location. When it is used for P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com