Spherical graphite superfine classifier

A spherical graphite and classifier technology, which is applied in the direction of the swirl axis can be reversed, the swirl device, etc., can solve the impact of classification efficiency and classification accuracy, material classification yield low classification quality, secondary air intake Small air volume and other problems can enhance the quality stability, facilitate the adjustment of air pressure distribution, and achieve the effect of small pressure loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

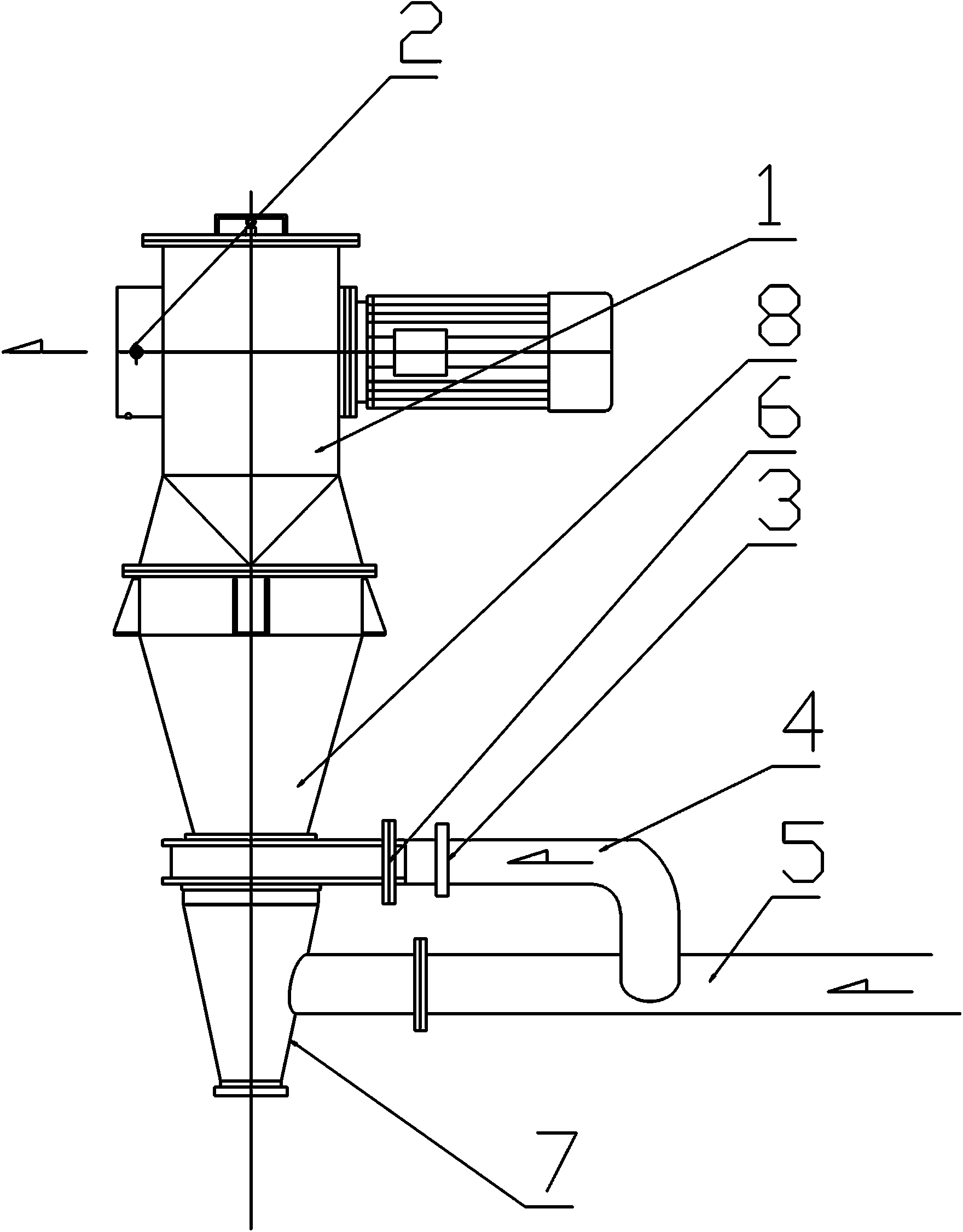

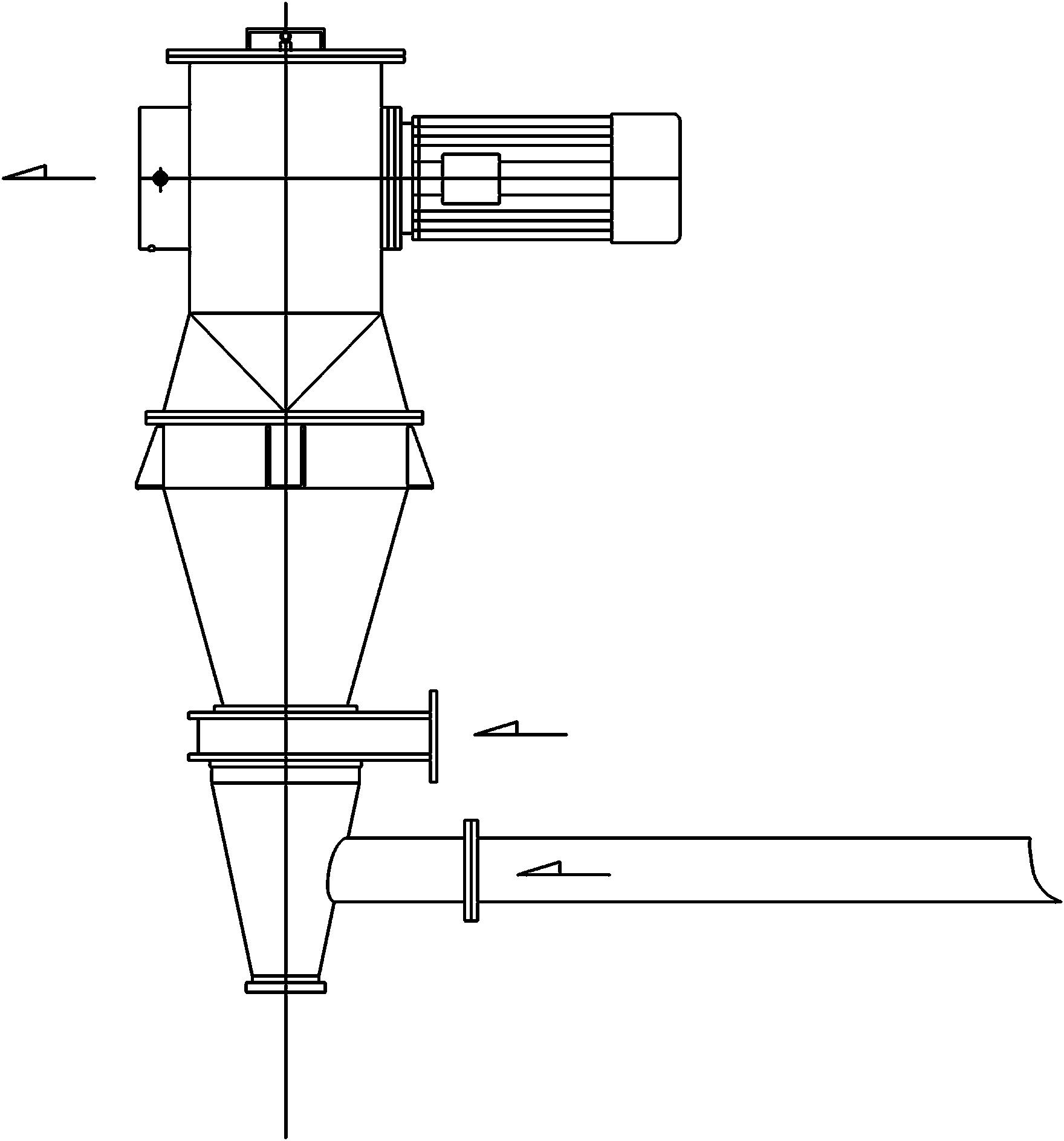

[0012] Such as figure 1 As shown in , a spherical graphite ultrafine classifier includes a classifier, the secondary air inlet 6 communicates with the feed pipe 5 through a branch pipe 4, and the branch pipe 4 is provided with an air valve 3 .

[0013] When in use, the raw material and air enter the classification chamber 1 through the secondary air inlet chamber 8 under the negative pressure suction at the discharge port 2, and enter the classification chamber 1 for classification. Under the high-speed rotation of the classification impeller rotor, the coarse particles above the classification diameter are thrown to the The inner wall of the cylinder stalls and slides down the wall surface, and the external secondary air enters the secondary air inlet chamber 8 from the feed pipe 5 through the branch pipe 4 through the air inlets evenly distributed on the cone, and the air sieve effect on the coarse particles will mix or The fine powder adhering to the coarse material is sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com