Plastic packing bag for express delivery

A packaging bag and plastic technology, applied in the field of plastic products, can solve the problems of being easy to be worn out, squeezed and broken, etc., achieve excellent anti-wear performance, reduce the effect of crushing and the probability of packaging bags being worn out

Inactive Publication Date: 2019-06-07

绍兴时薪塑料有限公司

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Ordinary plastic bags are easily worn out and crushed during this process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

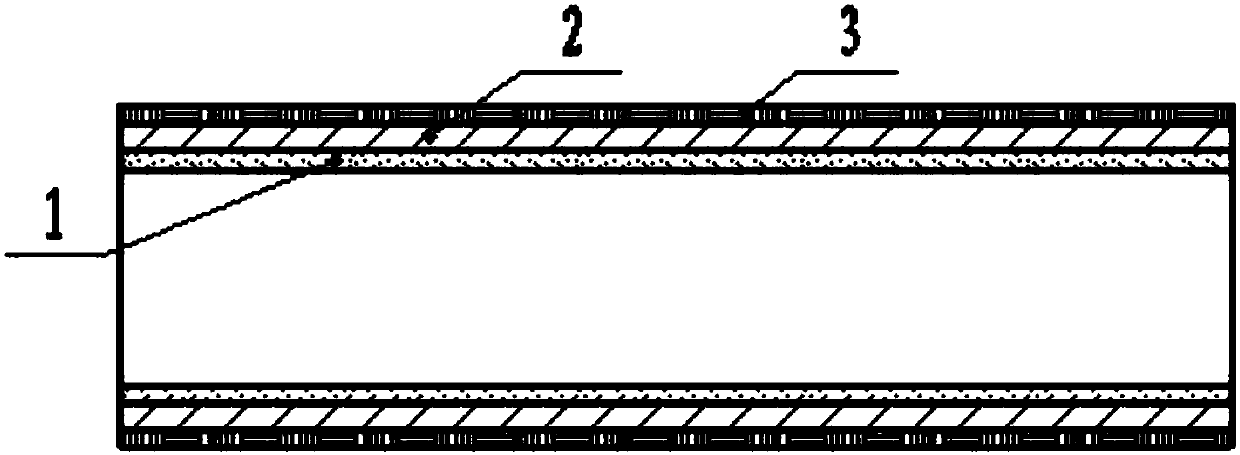

[0017] Embodiment 2: In embodiment 2, the raw material composition of wear-resistant outer layer 3 is: polyethylene 25 kilograms, polyimide 10 kilograms, glass fiber 1 kilogram, talcum powder 2 kilograms, polyphenylene sulfide 10 kilograms, its preparation The method is the same as in Example 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

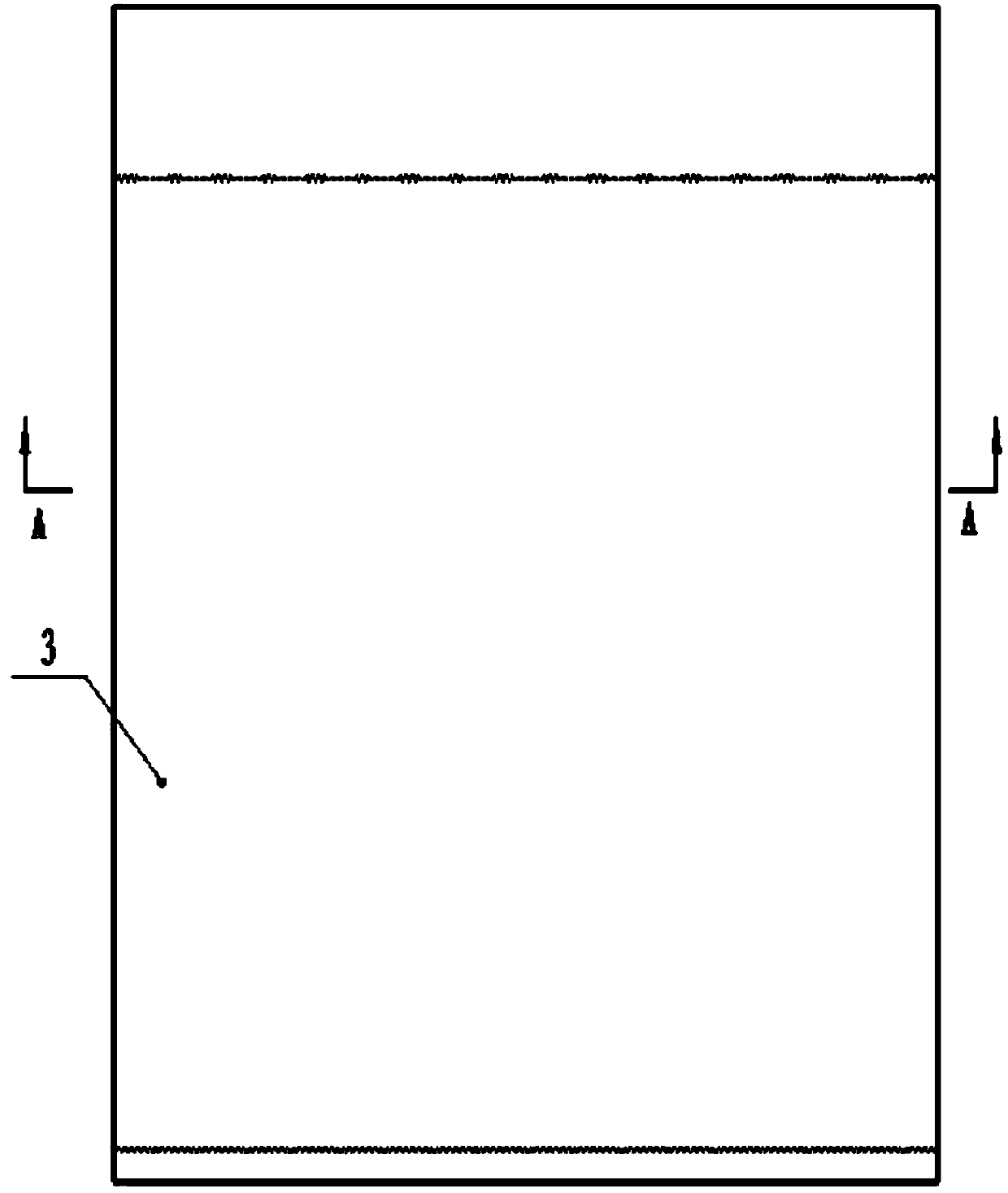

The invention discloses a plastic packing bag for express delivery, and relates to the technical field of plastic products. The plastic packing bag for express delivery comprises an inner layer, a pressure-resistant middle layer and a wear-resistant outer layer, wherein the inner layer is made of degradable plastics; the anti-vibration middle layer is made of an air cushion film; and the wear-resistant outer layer is prepared from the raw material components: polyethylene, polyimide, glass fiber, talcum powder and polyphenylene sulfide. Compared with the prior art, the plastic packing bag forexpress delivery provided by the invention is provided with the anti-vibration middle layer and the wear-resistant outer layer, the anti-vibration middle layer is made of the air cushion film, and airis fully filled in the air cushion film middle layer, so that the plastic packing bag is light in weight and high in resilience, and has anti-vibration and wear-resistant performances; and the wear-resistant layer adopts the polyimide added with the glass fiber and the talcum powder as the material so as to have an excellent wear-resistant performance, so that under the rough parcel delivery manner, the probabilities of crushing articles in parcels and wearing the packing bag are greatly reduced.

Description

technical field [0001] The invention relates to the technical field of plastic products, in particular to a plastic packaging bag for express delivery. Background technique [0002] In the past, people generally used paper envelopes when express mail, the moisture resistance of paper envelopes is not good, and the surface is easy to be worn out; compared with paper envelopes, plastic flexible packaging has outstanding advantages such as moisture resistance and barrier properties , and the cost is low, but ordinary plastic packaging bags are easily worn out because of their thin layer. [0003] Nowadays, with the development of the logistics industry and the fast pace of life and work, people focus their shopping on the Internet. As the volume of online shopping continues to expand, the demand for packaging bags for packaging objects also increases. Every day A large number of packages need to be packaged and transported, which greatly exceeds the workload of logistics perso...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65D30/08B32B3/26B32B27/32B32B27/28B32B27/06C08L23/06C08L79/08C08L81/02C08K7/14C08K3/34

Inventor 王立明

Owner 绍兴时薪塑料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com