Fan volute intermediate plate guide vane air inlet structure of smoke exhaust ventilator

A technology of range hood and air intake structure, applied in the direction of machine/engine, mechanical equipment, liquid fuel engine, etc., can solve the problems of increasing noise, increasing energy consumption, increasing the outer diameter of the volute, etc., to achieve efficiency The effect of improving and increasing the air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

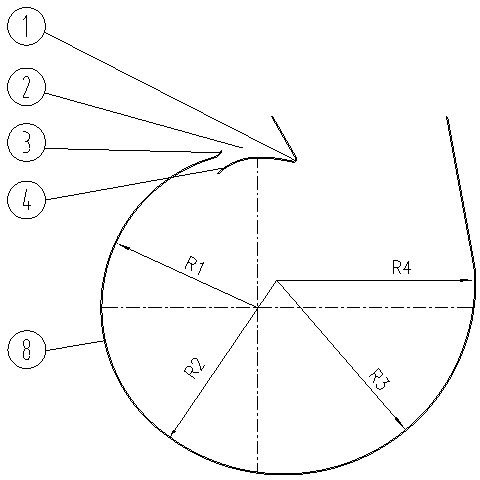

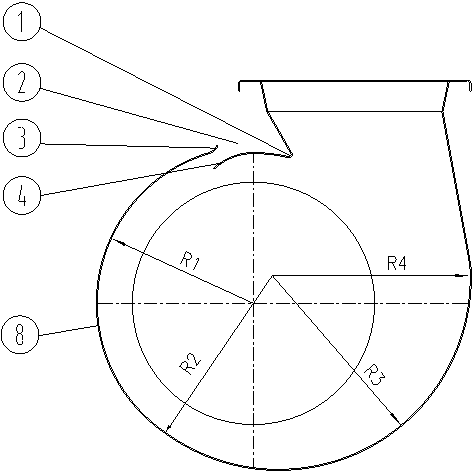

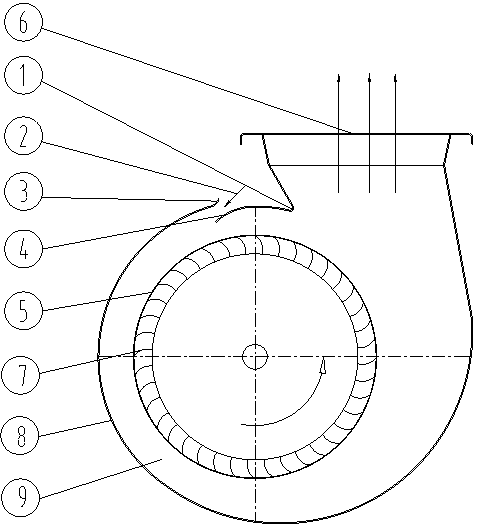

[0017] see figure 1 The guide vane inlet structure of the fan volute middle plate of the range hood includes an annular middle plate 8 that can be connected with the front cover plate and the rear cover plate of the volute, and the volute tongue 1 angle on the annular middle plate 8 is designed to prevent The air volume does not enter the outlet and re-flows to the volute. The rear end of the volute tongue 1 is provided with an air inlet 2.

[0018] see figure 2 ; The central arc of the volute R2 is the same size as the central arc of R1, without arc displacement, so that the volume of the volute can be made smaller.

[0019] see image 3 The rear end of the volute tongue 1 at the front end of the annular middle plate 8 has an air inlet 2, so that after the fan blade 7 of the impeller 5 passes through the volute tongue 1, the airflow is introduced from the air inlet 2 through the air inlet deflector 4 immediately, so that the efficiency of the fan is improved , the air vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com