Quick and dynamic vacuum calibration method for vacuum gauge

A technology of dynamic calibration and calibration method, which is applied in the direction of measuring devices, instruments, and measuring fluid pressure, etc., which can solve the problems that are difficult to meet the application requirements of millisecond-level dynamic vacuum calibration, long valve opening and closing time, and large upstream chamber volume. Dynamic response evaluation ability, shortening the establishment time, and ensuring the effect of rapidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below with reference to the accompanying drawings and examples.

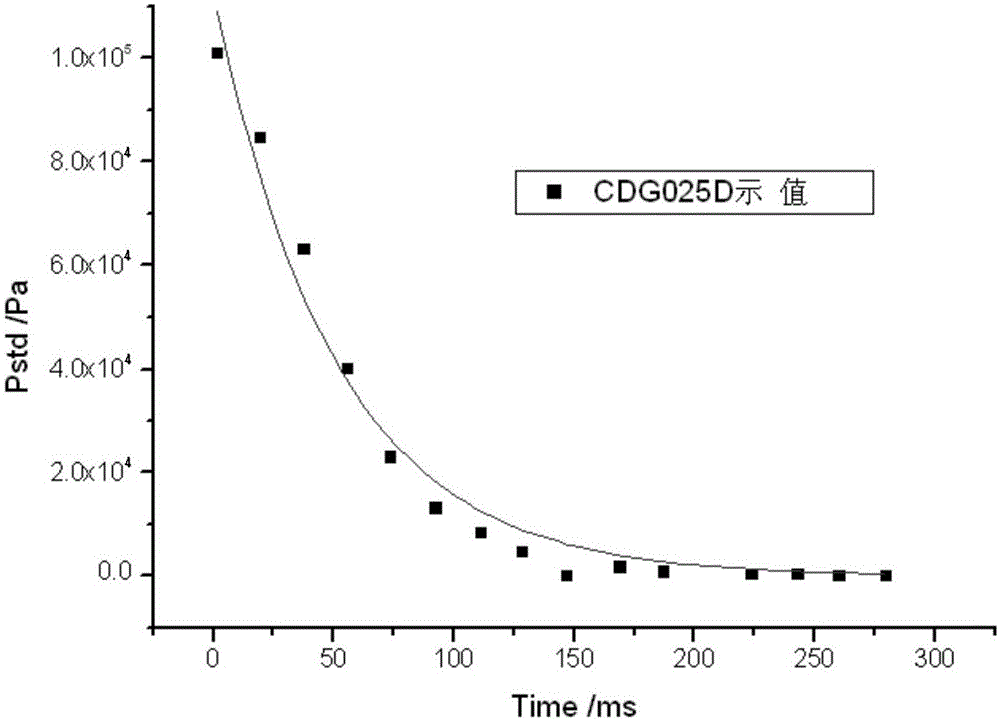

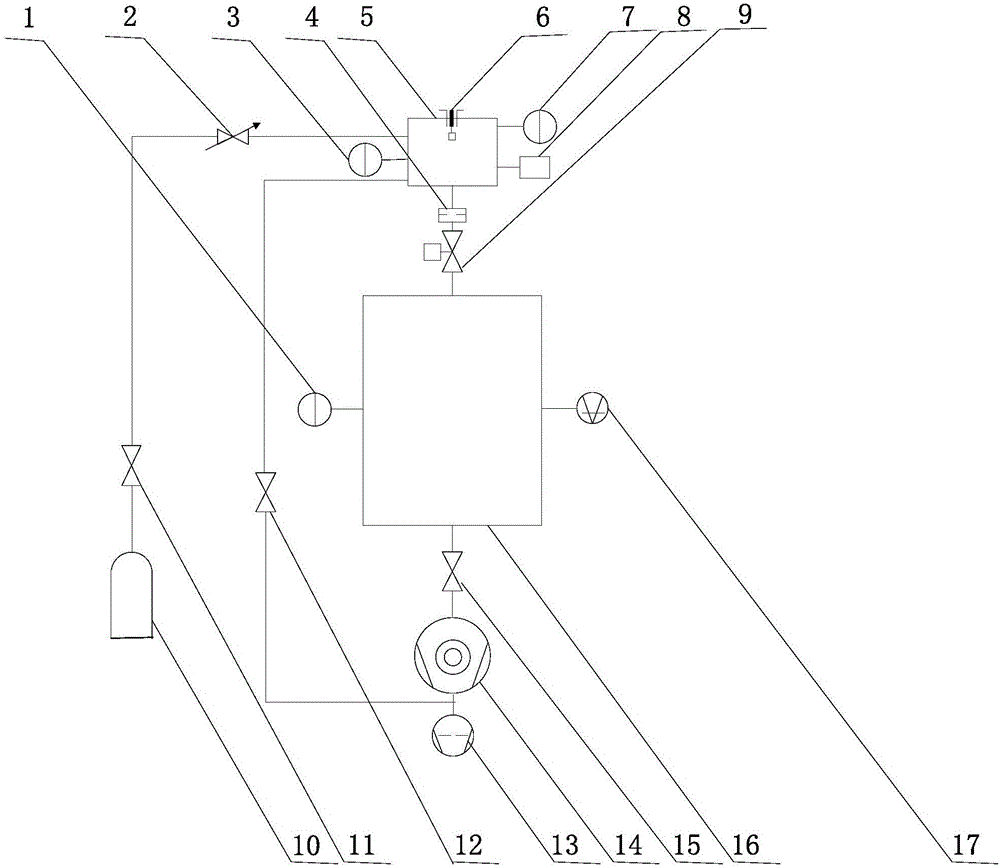

[0042] The present invention uses the structure of the static expansion method vacuum calibration device to perform dynamic calibration, but adopts a rapid expansion process. In order to achieve rapid expansion, replace the vacuum valve between the upstream chamber and the downstream chamber in the vacuum calibration device with an ultra-high vacuum gate valve, and determine whether to install and what conductance parameter is installed according to the response time of the calibrated vacuum gauge Components, thereby forming a dynamic vacuum calibration device to adapt to vacuum gauges with various response characteristics. Due to the complexity of the rapid expansion process, the present invention also needs to rebuild the standard pressure p std The calculation formula, using the pre-determined t-related conductance to calculate the standard pressure ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com