Multilevel centripetal turbine system

A turbine and series technology, applied in the field of multi-stage radial turbine systems, can solve the problems of limited expansion ratio and low efficiency of single-stage radial turbines, and achieve improved resource utilization efficiency, simple and compact structure, and system expansion. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

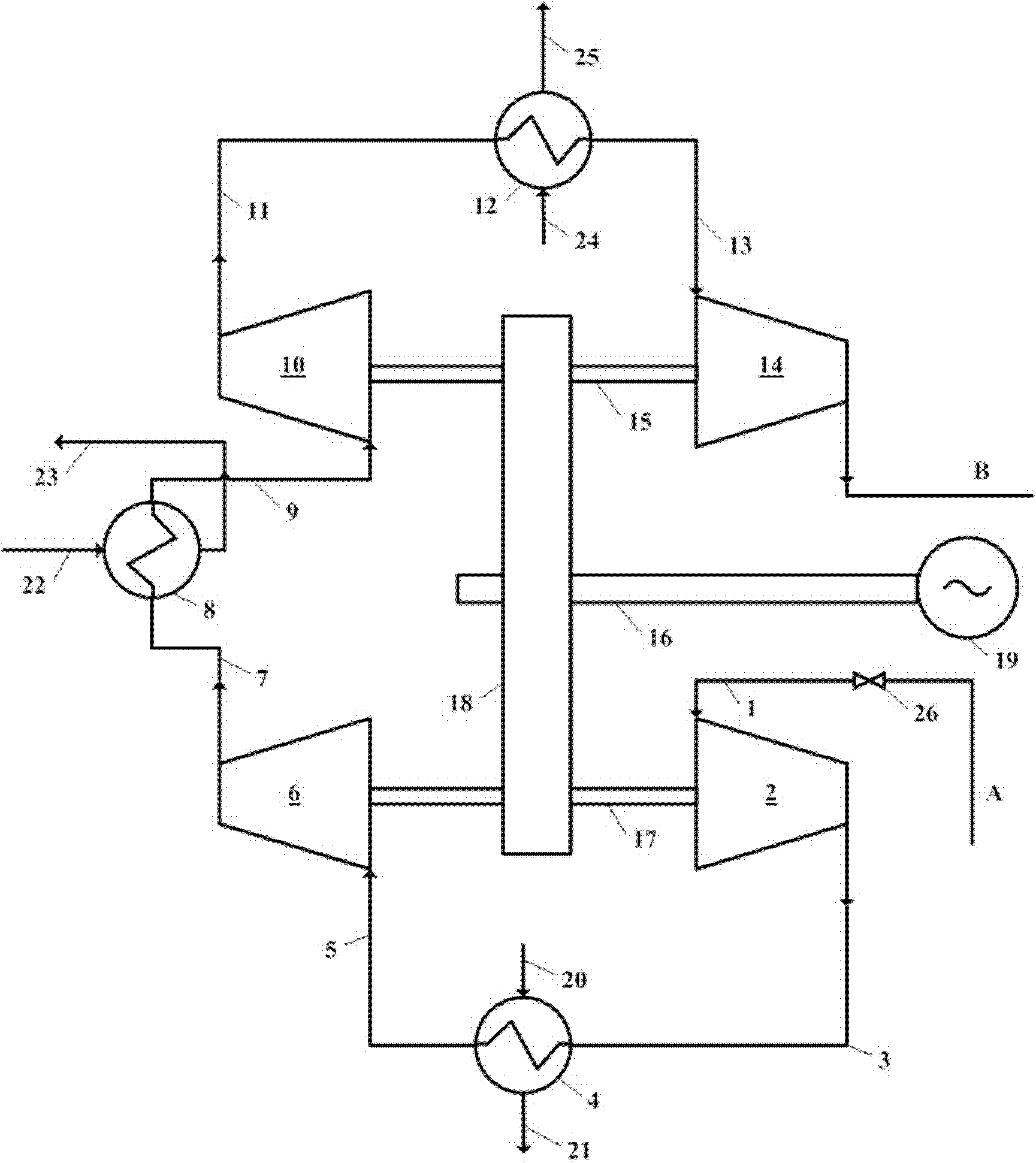

[0050] like figure 1 Shown is a schematic structural view of Embodiment 1 of the multi-stage centripetal turbine system of the present invention. This is a four-stage centripetal turbine system, including centripetal turbines 2, 6, 10, 14, heat exchangers 4, 8, 12, gear box 18, generator 19, regulating valve 26, shafts 15, 16 , 17, pipelines 1, 3, 5, 7, 9, 11, 13, 20, 21, 22, 23, 24, 25 and working air.

[0051] The first-stage centripetal turbine 2 and the second-stage centripetal turbine 6 are fixed back-to-back through a shaft 17 , and the third-stage centripetal turbine 10 and the fourth-stage centripetal turbine 14 are back-to-back fixed through a shaft 15 . The shafts 15, 17 are connected to the main shaft 16 through the gear box 18, and the main shaft 16 is fixedly connected to the rotating shaft of the generator 19. The first-stage centripetal turbine 2 communicates with the second-stage centripetal turbine 6 through pipeline 3, heat exchanger 4, and pipeline 5; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com