Water-soluble biodegradable material, and its preparing method and foamed product

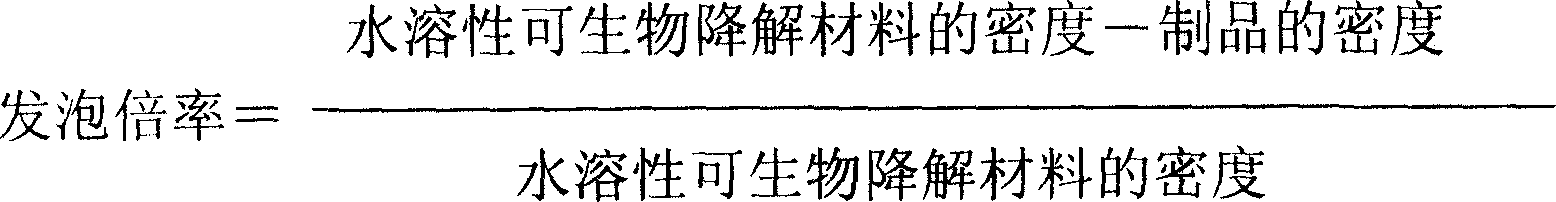

A biodegradable material and water-soluble technology, applied in the field of foaming products, can solve the problems of poor plasticity, difficult foaming and molding, etc., and achieve the effect of good foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the biodegradable material provided by the present invention comprises mixing polyvinyl alcohol containing starch, polyhydric alcohol and water to form a mixture, heating and melting the mixture, then extruding and granulating the obtained melt to obtain pellets, and then The pellets are mixed with blowing agent.

[0027] The preparation method of the water-containing polyvinyl alcohol of the present invention comprises fully contacting water and the polyvinyl alcohol under stirring conditions, mixing uniformly, and swelling to obtain the water-containing polyvinyl alcohol. The purpose of fully contacting water and polyvinyl alcohol is to expand the intricately intertwined polyvinyl alcohol molecular chains to the greatest extent through water, thereby achieving the purpose of reducing the melting temperature of polyvinyl alcohol. In order to fully swell the polyvinyl alcohol, the weight ratio of polyvinyl alcohol to water is preferably 0.5-5, ...

Embodiment 1

[0041] This example is used to illustrate the water-soluble biodegradable material provided by the present invention and its preparation method.

[0042] (1) Add water to 1.5 times the weight of polyvinyl alcohol (the degree of alcoholysis is 86, and the average degree of polymerization is 1700) at a stirring speed of 500 rpm, and after stirring for 5 minutes, water-containing polyvinyl alcohol is obtained. Wherein in the obtained water-containing polyvinyl alcohol, the weight ratio of polyvinyl alcohol to water is 2.3. 21 parts by weight of the water-containing polyvinyl alcohol obtained above are mixed with 15 parts by weight of glycerin, 15 parts by weight of sorbitol and 3 parts by weight of methylcellulose, and the mixer is first stirred at a low speed of 100 rpm for about 7 minutes, and then at 200 rpm Stir at a high speed per minute for 8 minutes, stir evenly and place for 4 hours; then add 40 parts by weight of starch, 2 parts by weight of zinc stearate, and 4 parts by...

Embodiment 2

[0046] This example is used to illustrate the water-soluble biodegradable material provided by the present invention and its preparation method.

[0047] (1) Add water to 2.5 times the weight of polyvinyl alcohol (the degree of alcoholysis is 90, and the average degree of polymerization is 2600) at a stirring speed of 400 rpm, and after stirring for 8 minutes, water-containing polyvinyl alcohol is obtained. Wherein in the obtained water-containing polyvinyl alcohol, the weight ratio of polyvinyl alcohol to water is 3.1. 27 parts by weight of the water-containing polyvinyl alcohol obtained above, 50 parts by weight of starch, 20 parts by weight of glycerin, and 3 parts by weight of epoxidized soybean oil are mixed, and the mixer is first stirred at a low speed of 100 rpm for about 7 minutes, and then stirred at a low speed of 200 rpm. Stir at high speed for 8 minutes, and stir evenly to obtain a mixture.

[0048] (2) The mixture obtained above is sent into a twin-screw extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com