Spiraster-type rotation device, engine, pneumatic motor, and compressor

A rotating device and a planetary spiral technology, applied in the field of planetary rotating devices, can solve the problems of low energy utilization rate, deformation of the cylinder body, large energy waste, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

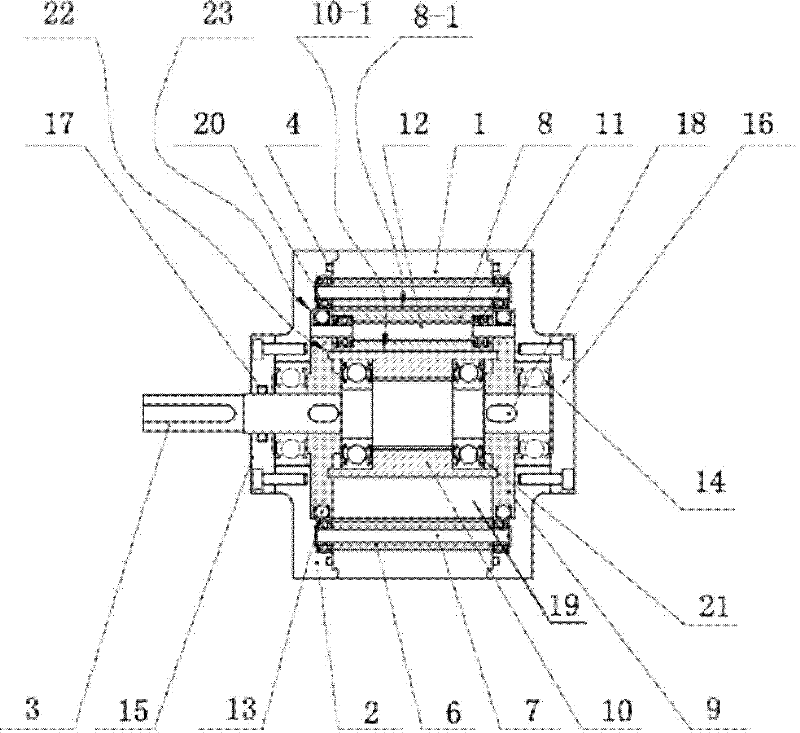

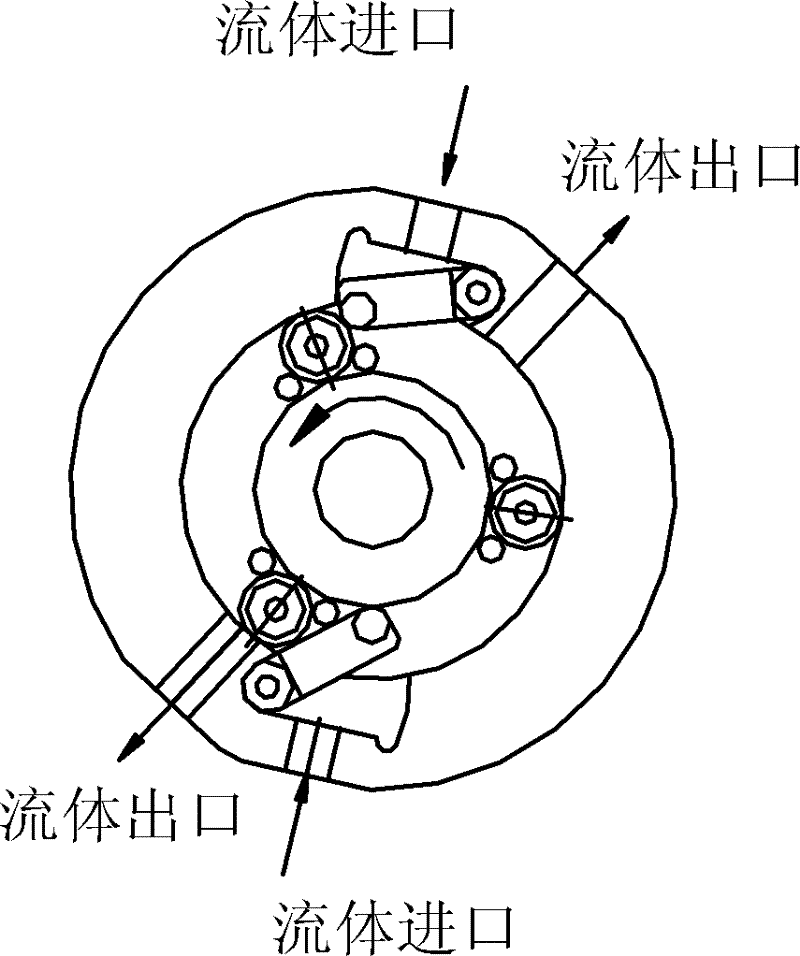

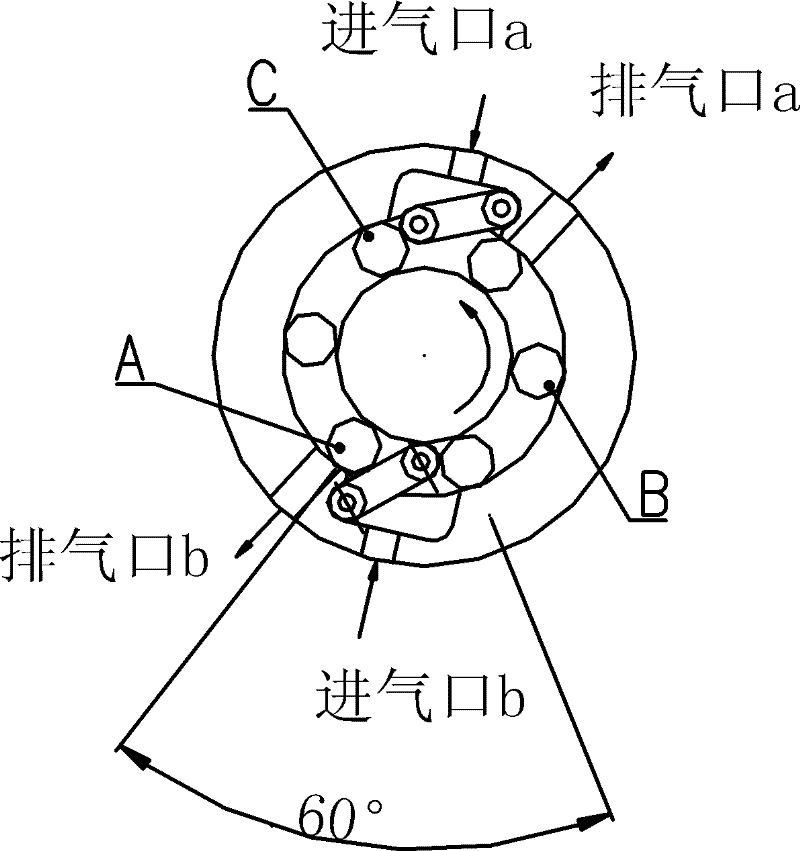

[0067] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. It should be noted that this application will mainly focus on the improvement of the star rotation device in the background patent application. For the convenience of understanding, firstly, the main components involved in this application document are numbered and described, as follows:

[0068] 1-cylinder; 1-1 first through hole;

[0069] 1-2 second through hole; 2- cylinder sealing end cover;

[0070] 3-spindle; 4-sealing ring;

[0071] 5-groove; 5-1-longitudinal side;

[0072] 6-rotary valve; 6-1-arc surface;

[0073] 7-rotary valve mandrel; 8-roller planetary piston wheel;

[0074] 9-Roller planetary piston wheel fixing flange; 10-Center sun wheel roller;

[0075] 11-bearing; 12-support shaft;

[0076] 13-sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com