Polyolefin resin pre-foamed particle having antistatic property, and molded article produced from the particle

A technology for polyolefin-based resins and foamed molded bodies, which is applied to the field of polyolefin-based resin pre-expanded particles and molded bodies obtained therefrom, and achieves the effects of improved productivity, less foaming, and stable dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

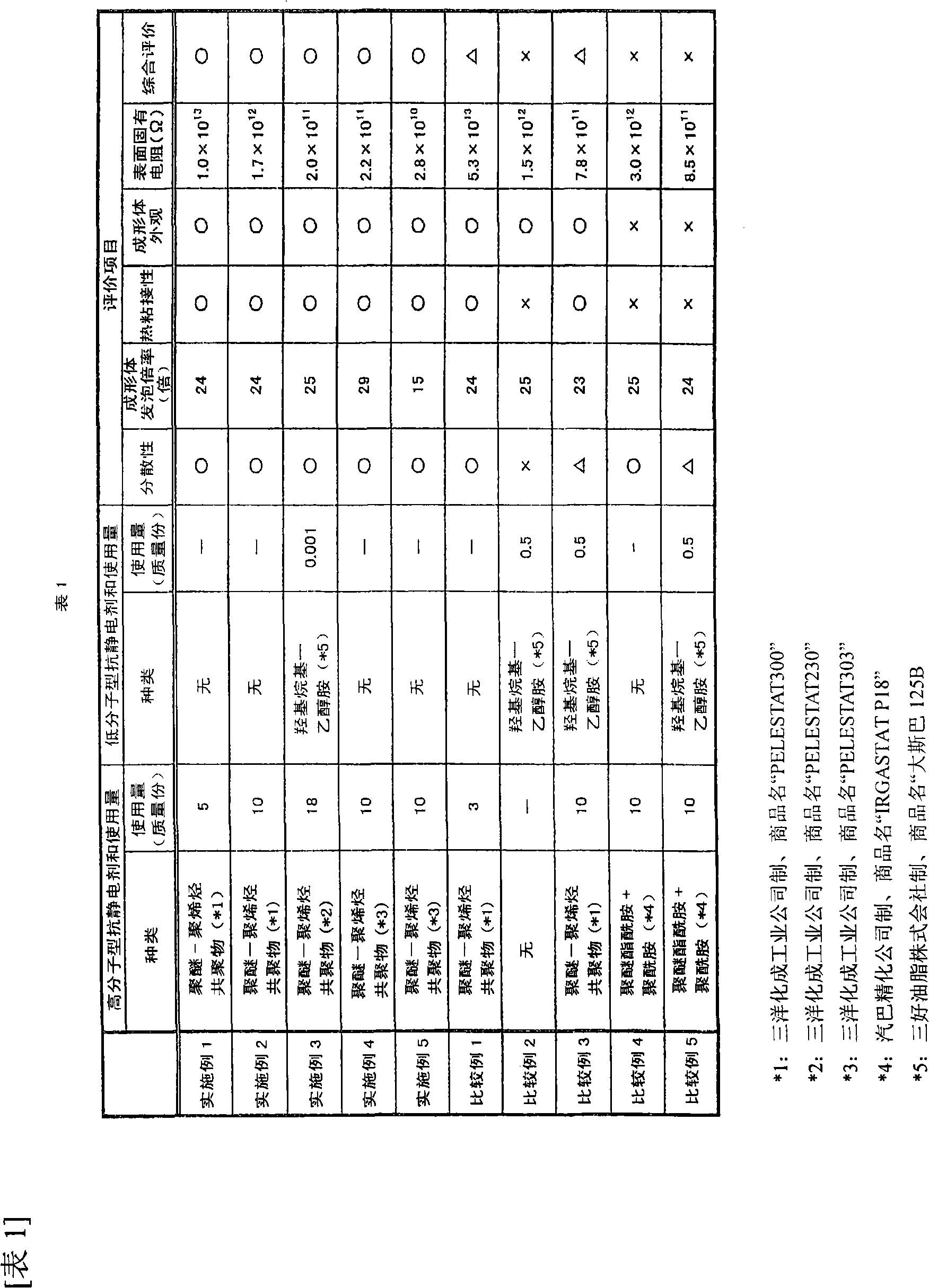

[0073] (Examples 1-2, Comparative Example 1)

[0074] Relative density is 0.9g / cm 3 100 parts by weight of an ethylene-propylene random copolymer (manufactured by Primeman Polymers Co., Ltd., E317) with an MFR of 7.0 g / 10 minutes, as a polyether-polyolefin resin block copolymer-based antistatic agent, poly Ether-polypropylene block copolymer (manufactured by Sanyo Chemical Industry Co., Ltd., trade name "PELESTAT300") was mixed in the amount shown in Table 1, and after melting and kneading with an extruder, granulation obtained polyolefin resin particles ( 1.2 mg / granule), after filling 300 parts by weight of water, 100 parts by weight of the above-mentioned polyolefin resin particles, 0.8 parts by weight of calcium phosphate as a dispersant, and 0.03 parts by weight of sodium n-alkane sulfonate in a pressure-resistant container, as Foaming agent, add 12 parts by weight of isobutane, heat up to a specified temperature under stirring, after adjusting the internal pressure of t...

Embodiment 3

[0077]As the antistatic agent, a polyether-polyolefin resin block copolymer antistatic agent (manufactured by Sanyo Chemical Industry Co., Ltd., trade name "PELESTAT230") and a low-molecular antistatic agent hydroxyalkyl monoethanolamine (Miyoshi Oil Co., Ltd., trade name "Daspa (Daspa 1) 125B", the number of carbon atoms in the alkyl group is half of 12 and 14, and the molecular weight: 285.3), the amount used is the amount shown in Table 1, and all other conditions are the same as those in the implementation In the same manner as in Example 1, pre-expanded polyolefin resin particles and in-mold molded articles were obtained. The results are shown in Table 1. Here, the apparent magnification of the polyolefin resin pre-expanded particles was 16.7.

Embodiment 4

[0079] Relative density is 0.9g / cm 3 100 parts by weight of an ethylene-propylene random copolymer with an MFR of 7.0 g / 10 minutes, using a polyether-polyolefin resin block copolymer antistatic agent (manufactured by Sanyo Chemical Industry Co., Ltd., trade name "PELESTAT303") , mixed in the amount shown in Table 1, after melting and kneading with an extruder, polyolefin-based resin particles (1.2mg / grain) were obtained, and 400 parts by weight of water, the above-mentioned polyolefin-based resin particles were filled in a pressure vessel. After 100 parts by weight, 1.4 parts by weight of calcium phosphate as a dispersant and 0.035 parts by weight of sodium n-alkanesulfonate, as a foaming agent, add 14 parts by weight of isobutane, heat up to a predetermined temperature under stirring, and adjust the internal pressure of the container Afterwards, the aqueous dispersion was released to the atmospheric pressure through the small hole nozzle arranged at the lower part of the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com