Swirl type triangle crossarm hinge space extending arm

A triangular and extending arm technology, which is applied to space navigation equipment, space navigation vehicles, aircraft, etc., can solve the problems of confidentiality, the coiled space extension arm that has not been successfully applied to spacecraft, and the late start of research, etc., to achieve a simple mechanism form, simplifies assembly layout and inspection, reduces mass effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

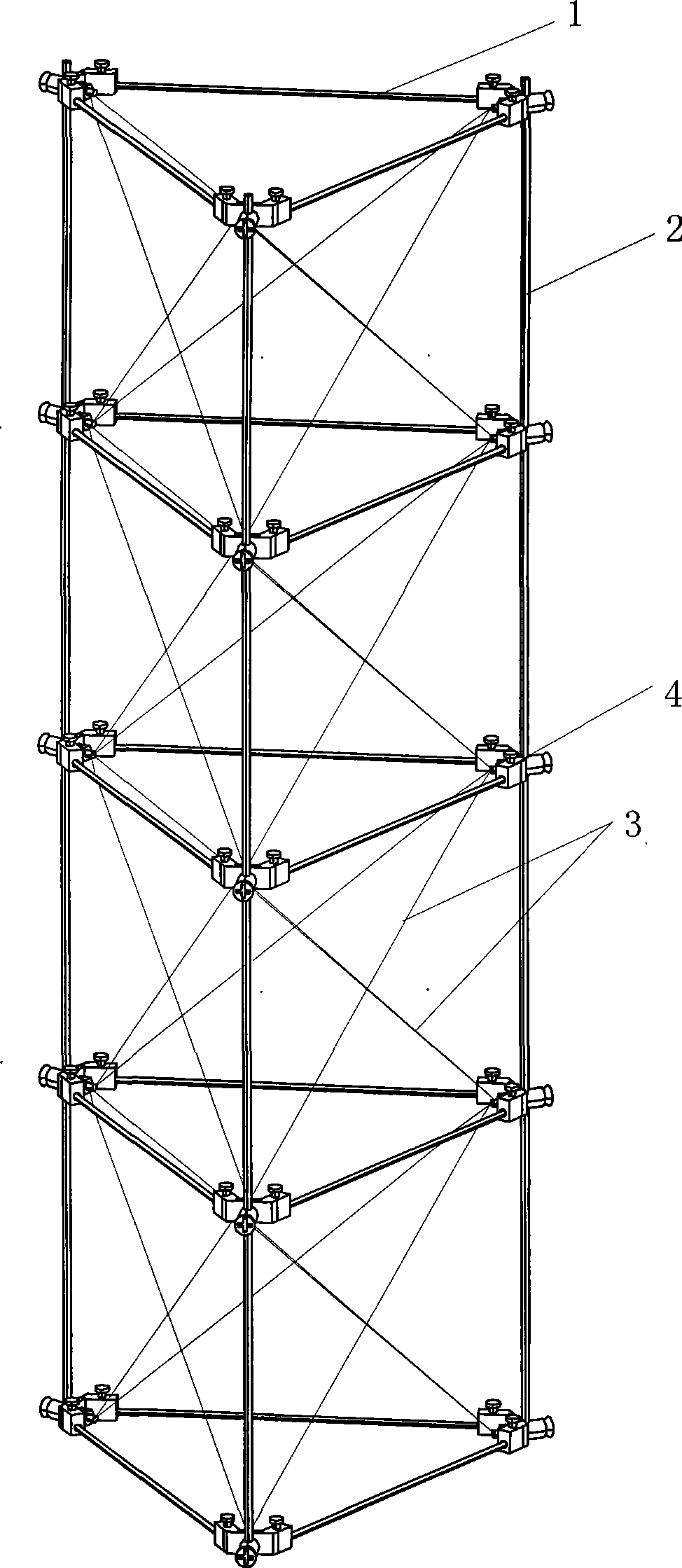

[0023] like figure 1 As shown, the present invention has a coiled triangular horizontal frame with a hinged space extension arm, and its technical solution is: the extension arm includes: several hinged triangular horizontal frames 1, three longitudinal rods 2 and several diagonal stiffening cables 3.

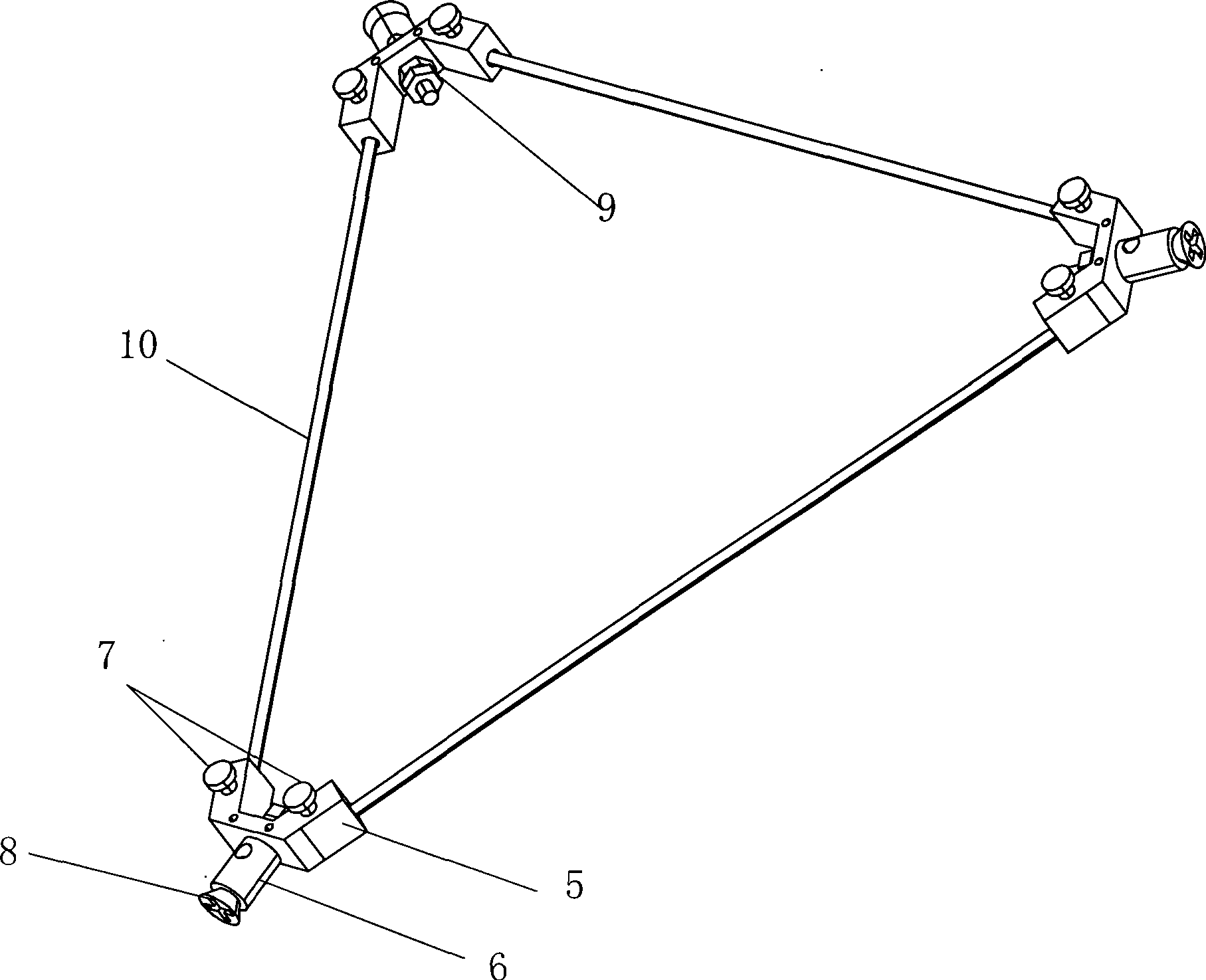

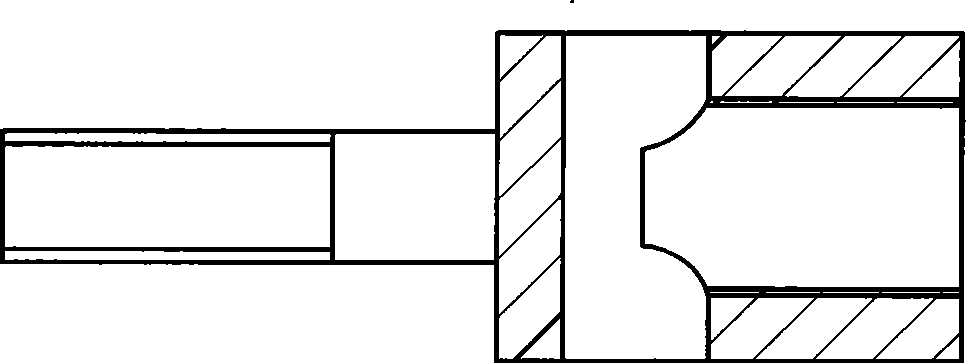

[0024] like figure 2 , the articulated triangular cross frame is composed of three triangular hinged joints 4 and three titanium-nickel alloy short rods 10, which provide lateral support for the longitudinal rods. The triangular joint 4 is composed of a 60° connector 5 , a stepped cylindrical joint 6 , three screws and two nuts 9 . The end of the titanium-nickel alloy short rod 10 is fixed in the hole of the 60° connector 5 through two M2 screws 7; the 60° connector is also provided with two Φ1mm holes for fixing the diagonal stiffening cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com