High-filling biodegradable radiation cross-link foam material and method for preparing same

A biodegradable and radiation cross-linking technology is applied in the field of highly filled biodegradable radiation cross-linked foam materials and their preparation, which can solve the problems of poor mechanical properties, poor water resistance, poor product durability, etc. Good durability and radiation dose reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

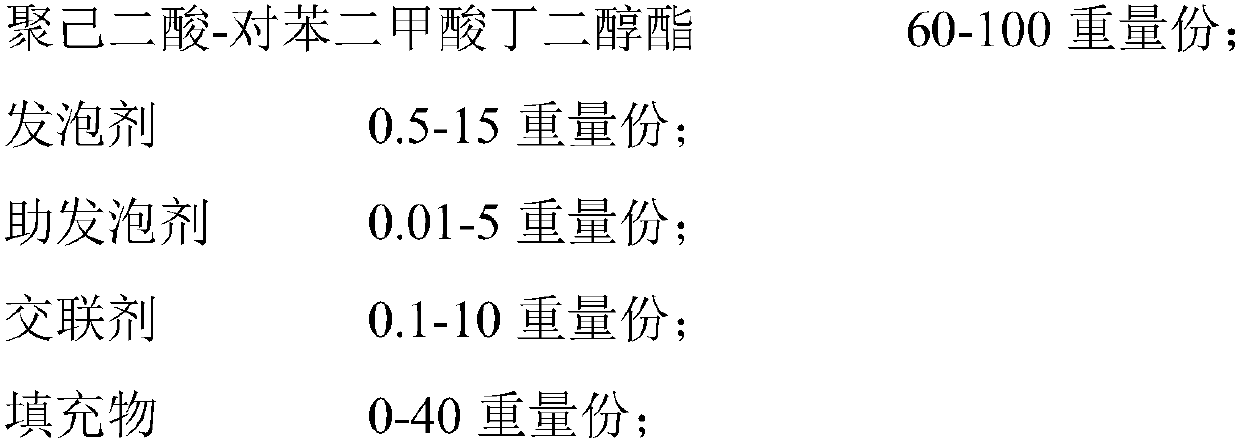

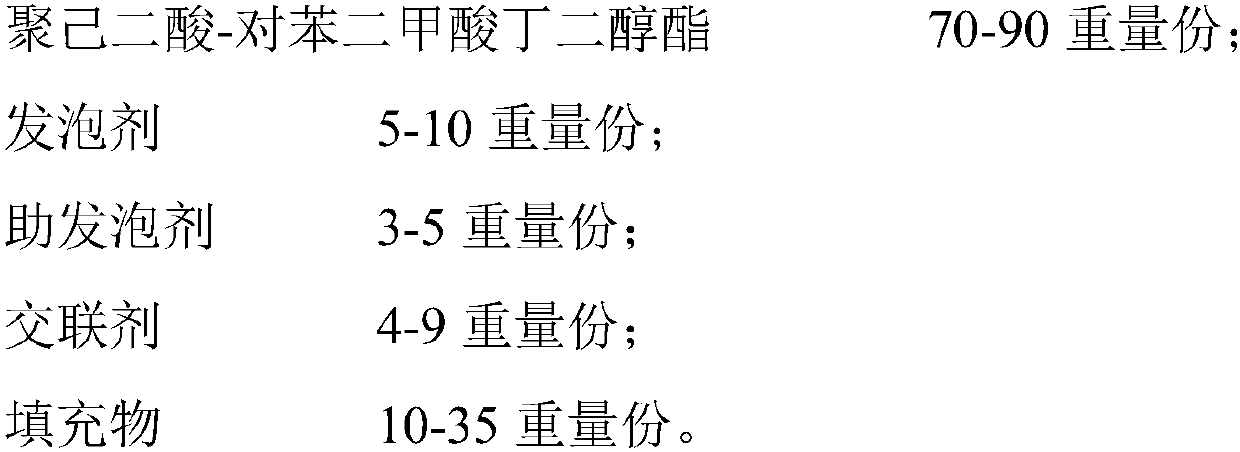

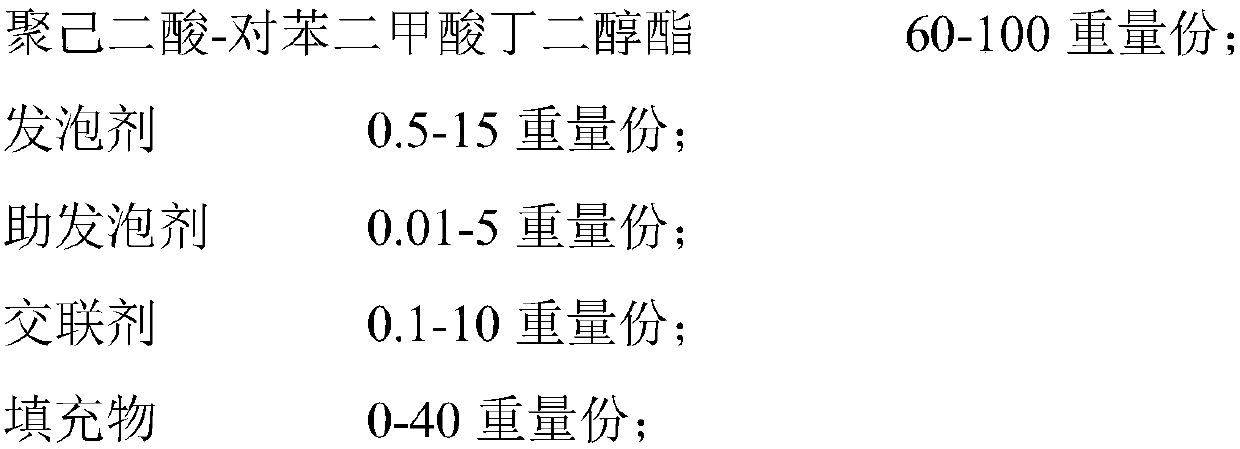

[0032] The preparation method of highly filled biodegradable radiation crosslinked foam material of the present invention, the steps are as follows:

[0033] Step 1. Weigh each raw material according to the composition and parts by weight, and add it to a twin-screw extruder for mixing and granulation. The mixing and granulation temperature is 80-170°C. Extrude the sheet on the machine, the thickness of the sheet is 0.5-3.0mm, preferably 1mm, and the extrusion temperature is 100-170°C;

[0034] Step 2, performing radiation crosslinking on the blend sheet in air at room temperature, with an irradiation dose of 0.5-9KGy, to obtain a precrosslinked material;

[0035] Step 3, further cross-linking the pre-crosslinked material in a hot water bath at 50-80°C for 2-48 hours to obtain a cross-linked material;

[0036] Step 4. Foam the cross-linked material in a vertical or horizontal foaming furnace at a temperature of 190-250°C for 1-20 minutes, preferably at 220-240°C for 4-10 minu...

Embodiment 1

[0039] Highly filled biodegradable radiation crosslinked foam material: 100 parts by weight of polybutylene adipate-terephthalate, 5 parts by weight of azodicarbonamide, 1 part by weight of zinc oxide and vinyltrimethylsilane 0.5 parts by weight.

[0040] The preparation of the above-mentioned high-filling biodegradable radiation-crosslinked foam material: take each raw material according to the proportion, add it to a twin-screw extruder for mixing and granulation, the mixing and granulation temperature is 80-170 ° C, and the obtained pellets are obtained by single-screw extruder The extruder is extruded into a sheet, the extrusion temperature is 100-170°C, and the thickness of the sheet is 1.0mm. Then, an electron accelerator was used to pre-irradiate the sheet in air at room temperature with a radiation dose of 9KGy, and the pre-irradiated cross-linked sheet was further cross-linked in a hot water bath at 80°C for 2 hours. Finally, foaming was carried out in a vertical foa...

Embodiment 2

[0043] Highly filled biodegradable radiation cross-linked foam material: 60 parts by weight of polybutylene adipate-terephthalate, 40 parts by weight of starch, 5 parts by weight of azodicarbonamide, 1 part by weight of zinc oxide and It consists of 0.5 parts by weight of vinyltriethoxysilane.

[0044] The preparation of the above-mentioned high-filling biodegradable radiation-crosslinked foam material: take each raw material according to the proportion, add it to a twin-screw extruder for mixing and granulation, the mixing and granulation temperature is 80-170 ° C, and the obtained pellets are obtained by single-screw extruder The extruder is extruded into a sheet, the extrusion temperature is 100-170°C, and the thickness of the sheet is 1.0mm. Then, an electron accelerator was used to pre-irradiate the sheet in air at room temperature with a radiation dose of 9KGy, and the pre-irradiated cross-linked sheet was further cross-linked in a hot water bath at 60°C for 36 hours. F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com