Fireproof anti-condensation combined material and preparation method thereof

An anti-condensation group, ammonium polyphosphate technology, applied in the field of cable laying equipment, can solve the problems of poor durability of fixed sealing, poor temperature removal effect, low price of fireproof mud, etc. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

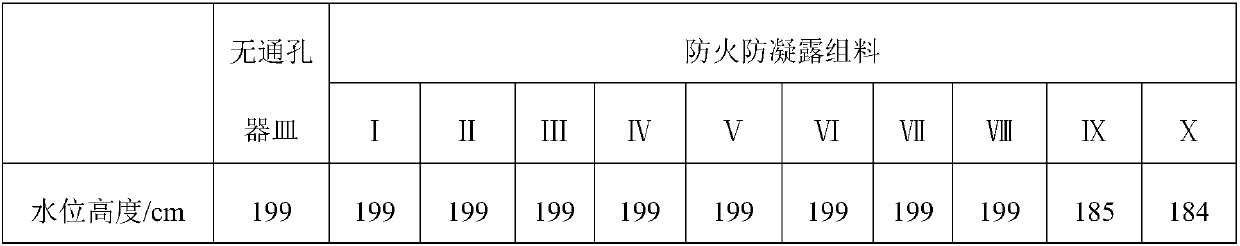

Examples

Embodiment 1

[0028] This example provides a fireproof and anti-condensation component, which is composed of A component, B component and C component with a mass ratio of 1:1:0.5. 491.4g of polyether polyol DL-1000D, monofluoro Pour 245.7g of dichloroethane, 238.8g of phosphoric acid triester and 6.8g of organic silicone oil into the reaction kettle, and stir at a speed of 33r / min for 6min to obtain a uniformly mixed component A, and 368.55g of expanded graphite and 122.85g of polyphosphoric acid Ammonium-APP1000 was poured into a mixing mixer and stirred for 10 minutes to obtain a uniformly mixed component C. The above-mentioned component A, component C and 982.8 g of polymethylene polyphenyl polyphenol Stir the isocyanate PM-200 in the bucket for 1min, mix well to obtain the fireproof and anti-condensation composition I, and use it immediately.

Embodiment 2

[0030] This example provides a fireproof and anti-condensation component, which is composed of A component, B component and C component with a mass ratio of 1:1:0.6. 756g of polyether polyol DL-1000D, monofluorine di Pour 47.25g of ethyl chloride, 132.3g of phosphoric acid triester and 9.45g of organic silicone oil into the reaction kettle, and stir at a speed of 33r / min for 6min to obtain a uniformly mixed component A. 340.2g of expanded graphite and 226.8g of ammonium polyphosphate -APP1000 is poured into a mixing mixer and stirred for 10 minutes to obtain a uniformly mixed component C, and the above-mentioned component A, component C and 945g of polymethylene polyphenyl polyisocyanate PM -200 Stir in the barrel for 2 minutes, mix evenly to obtain fireproof and anti-condensation composition II, and use it immediately.

Embodiment 3

[0032] This example provides a fireproof and anti-condensation component, which is composed of A component, B component and C component with a mass ratio of 1:1:0.7. 591.5g of polyether polyol DL-1000D, monofluoro 86.45g of dichloroethane, 227.5g of phosphoric acid triester and 4.55g of organic silicone oil are poured into the reaction kettle, and stirred at a speed of 33r / min for 6min to obtain a uniformly mixed component A, and 350.35g of expanded graphite and 286.65g of polyphosphoric acid Pour the ammonium-APP1000 into a mixing mixer and stir for 10 minutes to obtain a uniformly mixed component C. Put the above component A, component C and 910g of polymethylene polyphenyl polyisocyanate at the site where the fireproof and anti-condensation components need to be poured Stir the PM-200 in the barrel for 2 minutes, mix well to obtain the fire prevention and anti-condensation composition III, and use it immediately.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com