Preparation method of uniform-cell and high-buffer polylactic acid foamed material

A technology of polylactic acid foaming and polylactic acid, which is applied in the field of preparation of polylactic acid foaming materials, can solve problems such as poor cushioning performance, uneven cells, and low foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

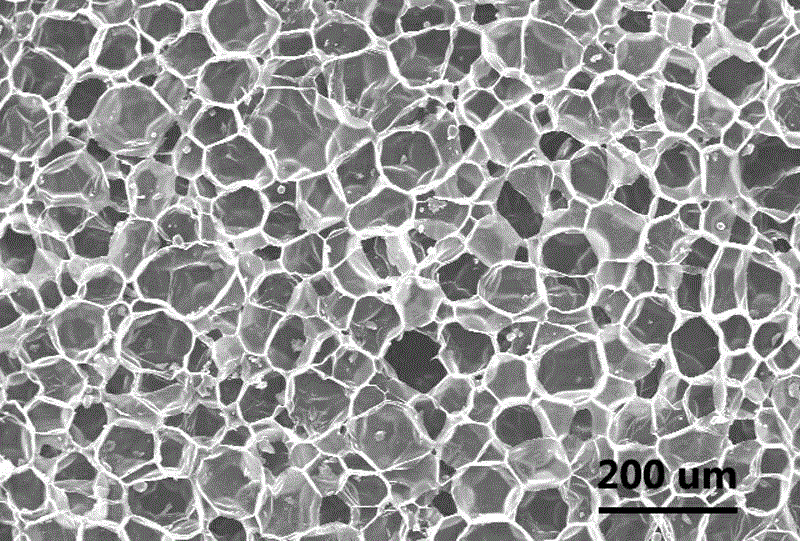

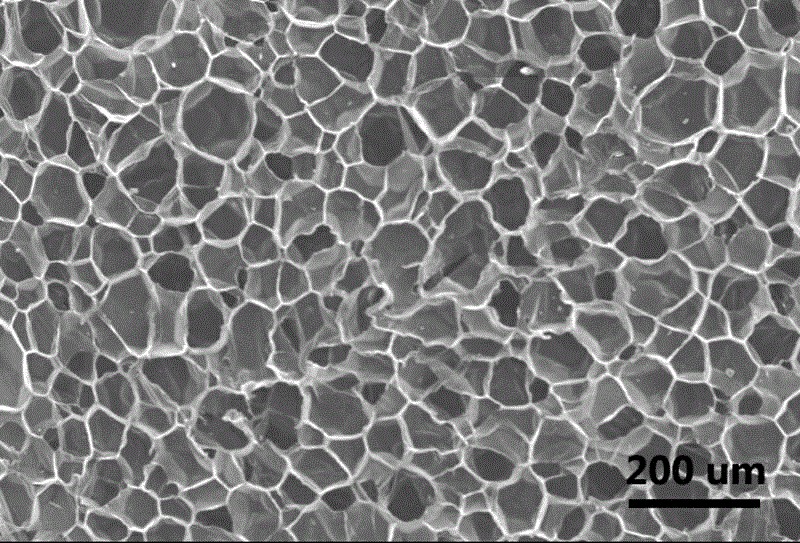

Image

Examples

specific Embodiment 1

[0025] A method for preparing a polylactic acid foam material with uniform cells and high buffering capacity. The foam material is processed from main materials and auxiliary materials. The main materials include polylactic acid, EVA elastomer, cellulose acetate propionate, esterified modified nano Cellulose, polylactic acid grafted maleic anhydride, gelatin, and auxiliary materials antioxidant, plasticizer, anti-ultraviolet agent. Calculated by the mass of polylactic acid as 100 parts, in the main material, EVA elastomer is 26 parts, cellulose acetate propionate is 12 parts, acetate-modified nanocellulose is 4 parts, polylactic acid grafted maleic anhydride is 6 parts 4 parts of gelatin. Among the auxiliary materials, the antioxidant, the plasticizer, and the anti-ultraviolet agent are all 3 parts.

[0026] The polylactic acid is poly-L-lactic acid, and its relative molecular weight is 140,000-200,000.

[0027] The acetate nanocellulose is diacetate nanocellulose, the degre...

specific Embodiment 2

[0040] The invention discloses a preparation method of polylactic acid foam material with uniform cells and high buffering capacity. The foam material is processed from main materials and auxiliary materials. The main materials include polylactic acid, EVA elastomer, cellulose acetate propionate, esterified modified nanocellulose, polylactic acid grafted maleic anhydride, gelatin, and auxiliary materials anti Oxygen, plasticizer, anti-ultraviolet agent. Calculated on the basis of 100 parts of polylactic acid, in the main ingredients, EVA elastomer is 30 parts, cellulose acetate propionate is 12 parts, acetate modified nanocellulose is 5.5 parts, and polylactic acid grafted maleic anhydride is 5.5 parts. part, 4.5 parts of gelatin. Among the auxiliary materials, antioxidant, plasticizer, and anti-ultraviolet agent are all 2.5 parts.

[0041] The polylactic acid is poly D-lactic acid, and its relative molecular weight is 160,000-250,000.

[0042] The acetate nanocellulose is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com