Power system of bicirculating two-level screw expander

A screw expander, power system technology, applied in geothermal energy systems, machines/engines, mechanical equipment, etc., can solve the problems of high heat source requirements, waste, small expansion ratio, etc., to achieve high cycle efficiency, low waste heat parameter requirements, The effect of a large expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

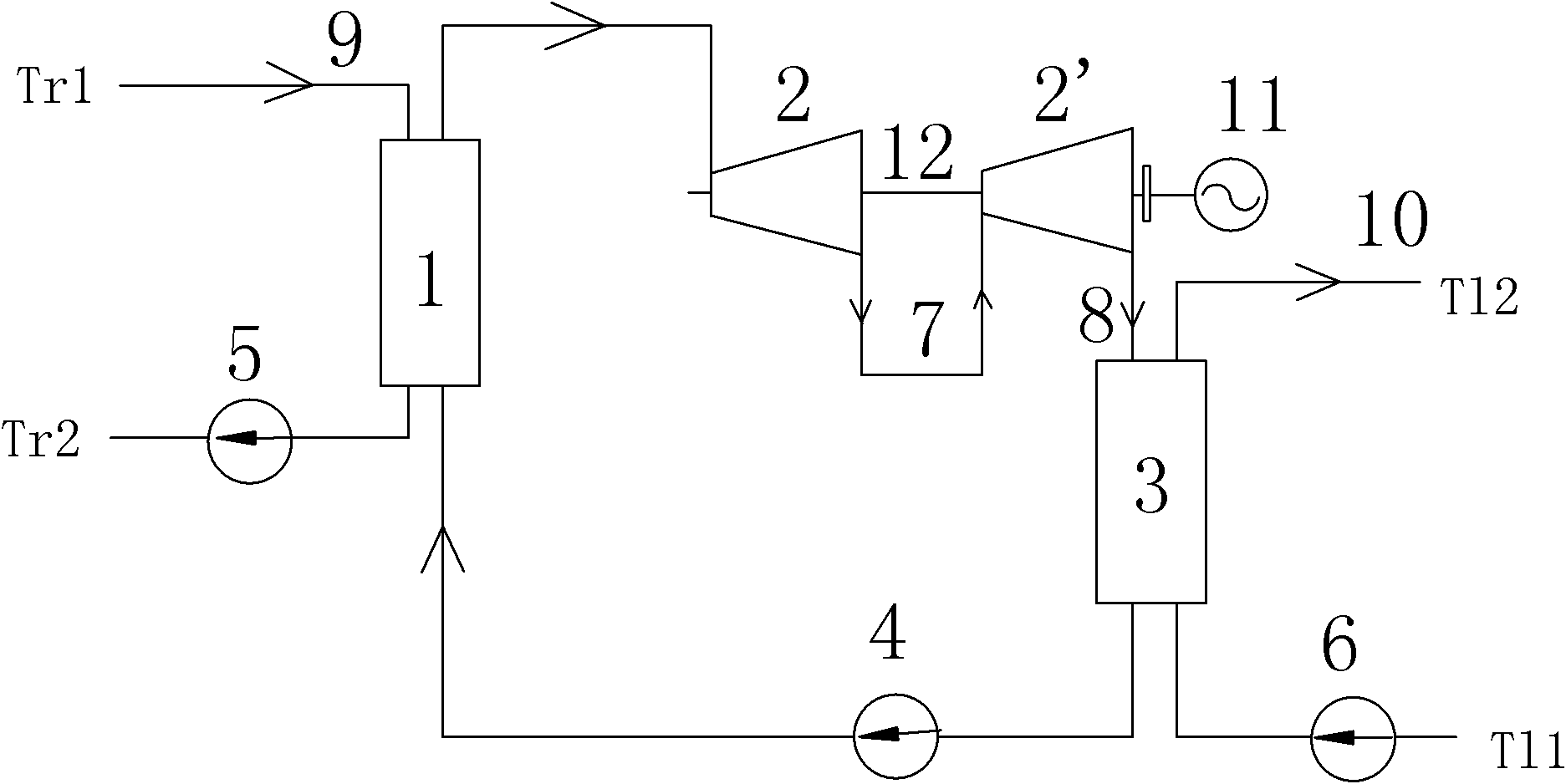

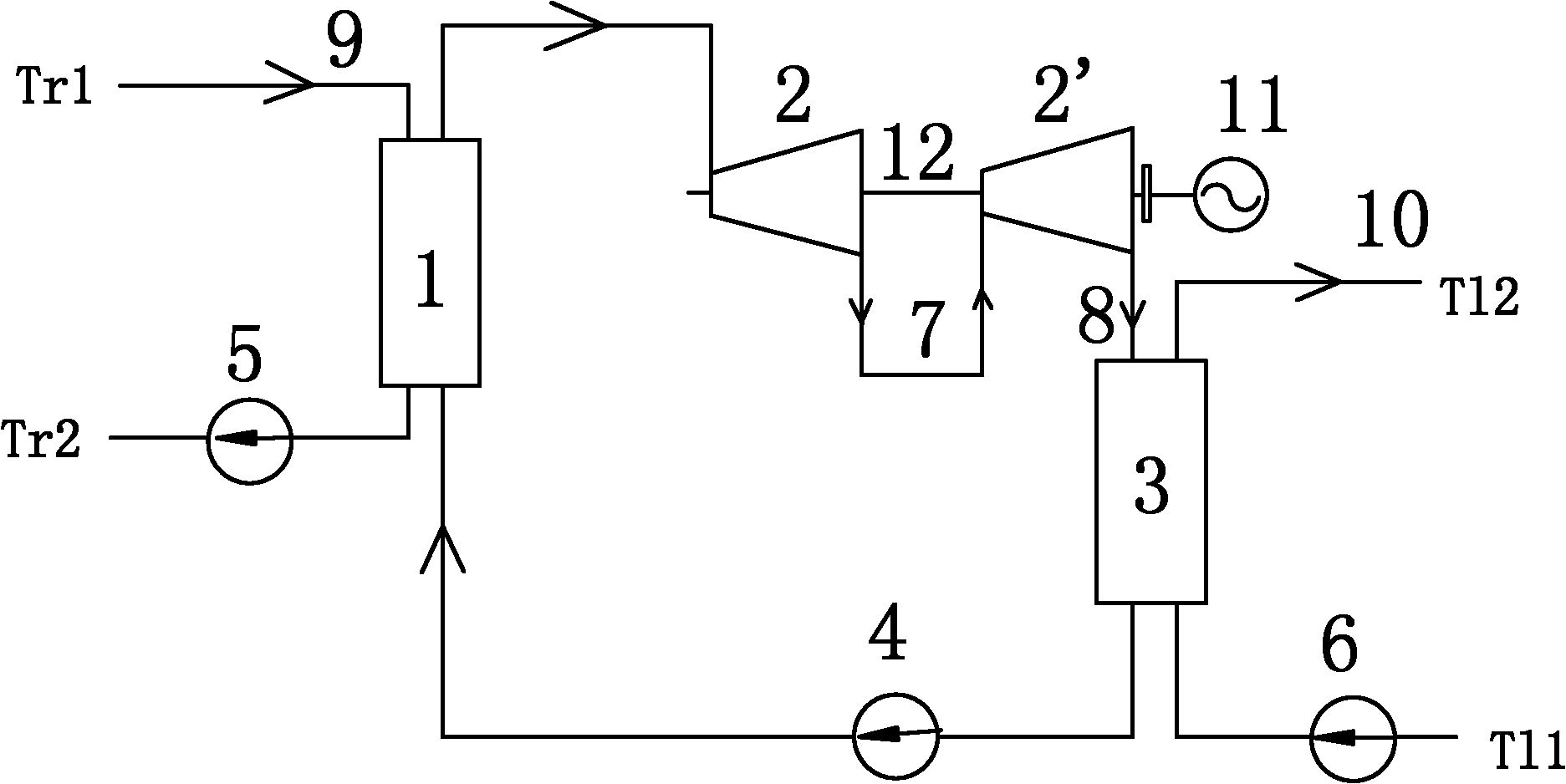

[0029] The dual-cycle two-stage screw expander power system of the present invention will be described in detail below with reference to the embodiments and drawings.

[0030] Such as figure 1 As shown, the double-cycle two-stage screw expander power system of the present invention includes: an evaporator 1 and a condenser 3, and a working medium circulation passage 8 is formed through a sealed pipeline connection between the evaporator 1 and the condenser 3, so An organic low-boiling-point working medium flows through the above-mentioned working medium circulation channel 8 . The heating passage 9 is formed by the evaporator 1, the heat source inlet TR1 and the heat source outlet TR2, and the cooling passage 10 is formed by the condenser 3, the cooling water inlet TI1 and the cooling water outlet TI2. A two-stage screw expander power device is arranged on the working medium circulation passage 8 between the working medium inflow sides of the condenser 3 . A working medium p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com