Engine air cylinder, two-stroke engine and control method for working circulation of two-stroke engine

A technology of an engine cylinder and a control method, which is applied in the direction of engine control, engine components, combustion engines, etc., can solve the problems of two-stroke engines such as low thermal efficiency, low ventilation quality, and short ventilation time, so as to reduce residual exhaust gas and improve Effect of scavenging efficiency and sufficient scavenging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

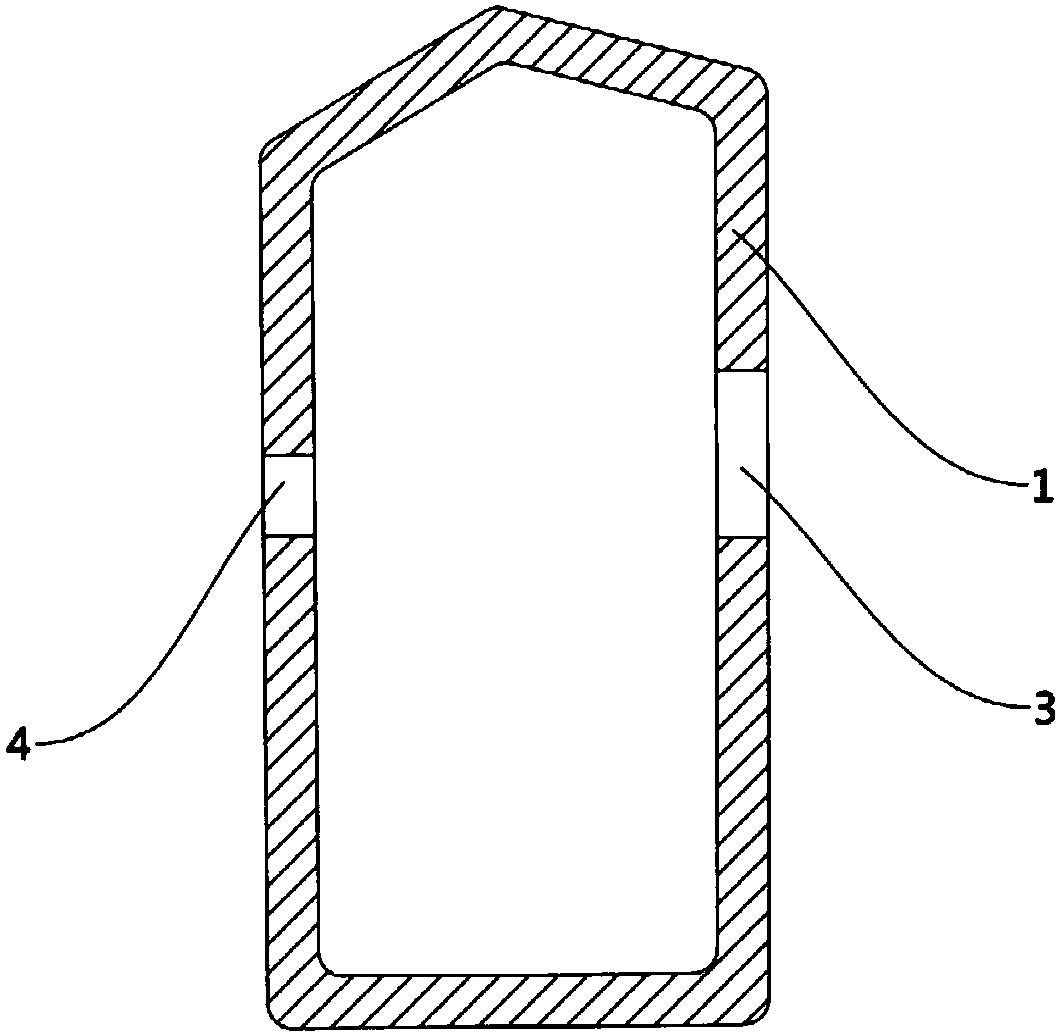

[0058] See figure 1 , an engine cylinder, comprising a cylinder body 1, the cylinder body 1 is provided with an exhaust hole 3 and a scavenging hole 4 passing through its side wall, and the exhaust hole 3 and the scavenging hole 4 are arranged oppositely, wherein the exhaust hole 3 The highest point of the exhaust hole is higher than the highest point of the scavenging hole 4, and the lowest point of the exhaust hole 3 is higher than the lowest point of the scavenging hole 4.

[0059] It should be noted that the cylinder body is mainly composed of a cylinder head, a cylinder block and a crankcase. The cylinder body is also provided with an intake hole for the fuel or air mixture to enter, and the piston moves up and down in the cylinder body through the crankshaft in the crankcase. move.

[0060] The exhaust hole and the scavenging hole in the engine cylinder are asymmetrically arranged. Compared with the existing engine cylinder, when applied to a two-stroke engine, when the...

Embodiment 2

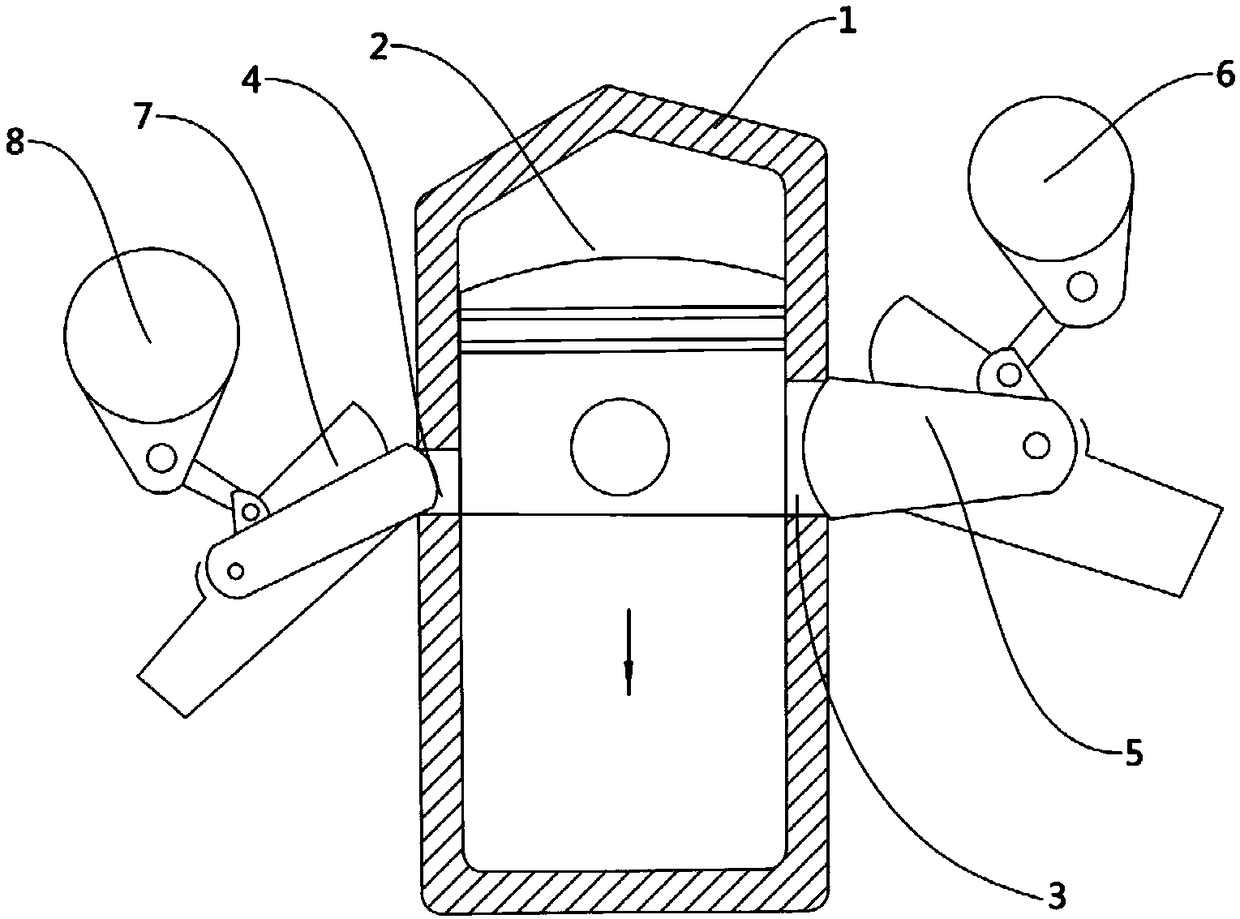

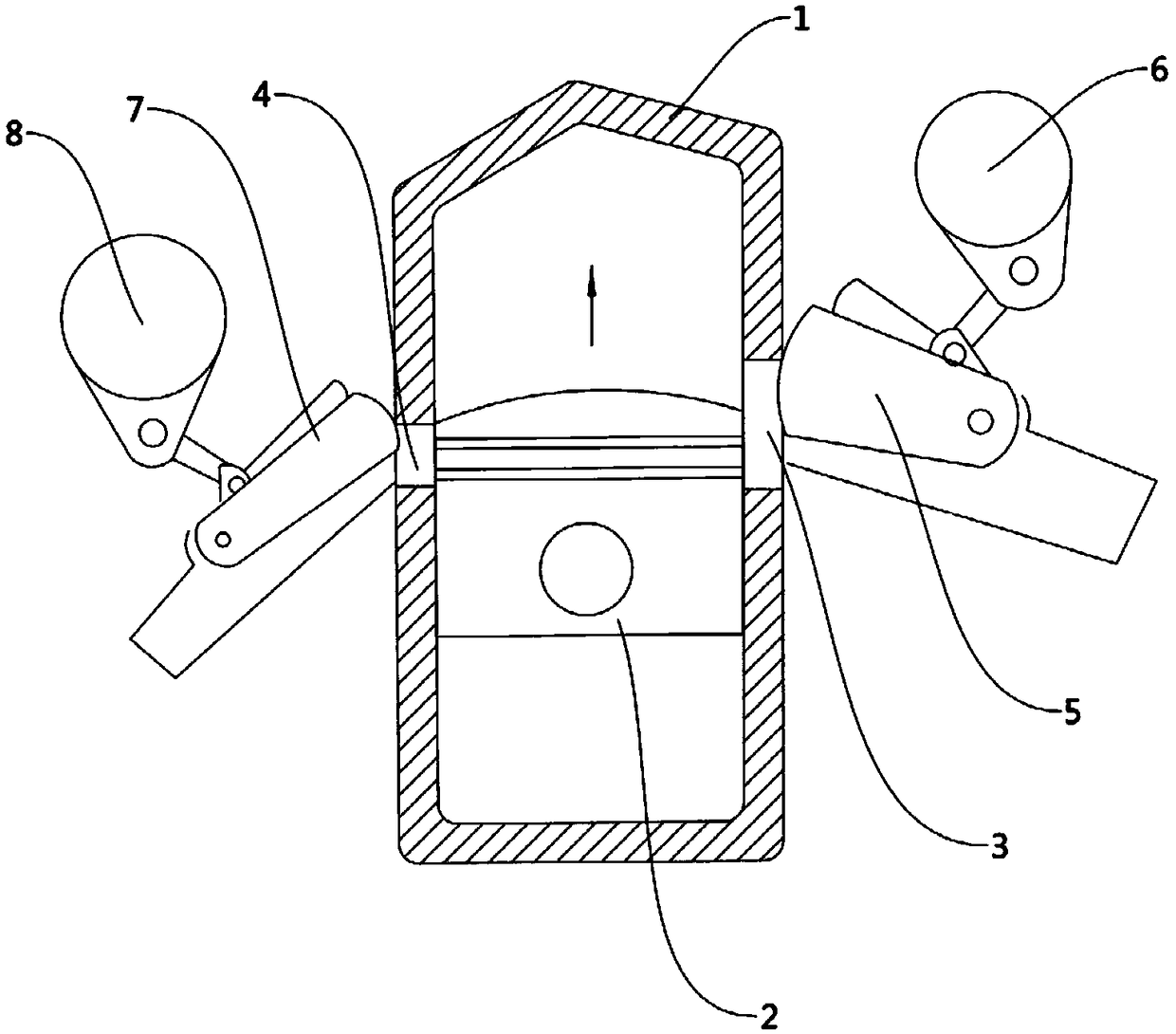

[0079] See Figure 4 , a method for controlling the working cycle of a two-stroke engine, using the above-mentioned two-stroke engine, comprising the following steps,

[0080] When the piston 2 moves upward from the bottom dead center in the cylinder body 1, the closing time of the scavenging hole 4 and the exhaust hole 3 is postponed;

[0081] When the piston 2 moves downward from the top dead center in the cylinder body 1, the opening time of the scavenging hole 4 and the exhaust hole 3 is delayed;

[0082] The operating conditions of the engine are judged, and the scavenging valve driving device 8 and the exhaust valve driving device 6 are individually controlled according to the judged engine operating conditions.

[0083] When the piston 2 moves downward from the top dead center in the cylinder body 1 and the top surface of the piston 2 moves from the highest point of the exhaust hole 3 to the lowest point of the exhaust hole 3, the exhaust valve drive device 6 drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com