Engine with compression ratio capable of being changed

A compression ratio, engine technology, applied in engine control, machine/engine, mechanical control, etc., can solve the problems of low combustion efficiency, difficult to meet the development requirements of supercharged engines, achieve simple structure and control, and save fuel consumption , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

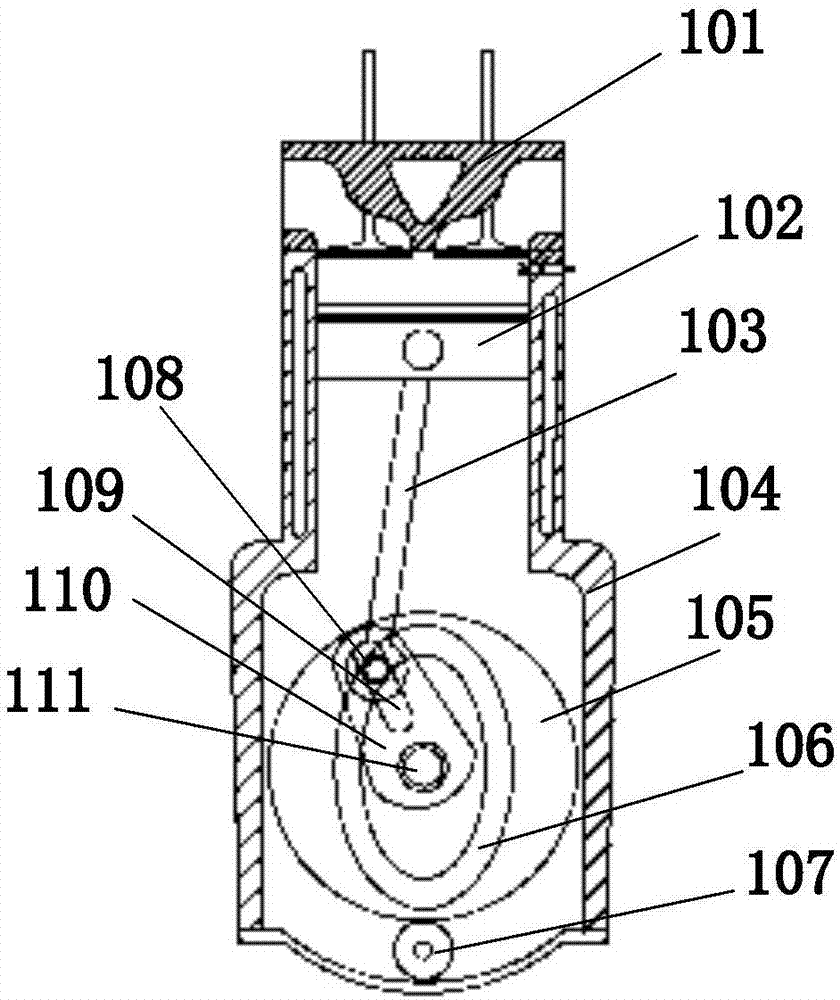

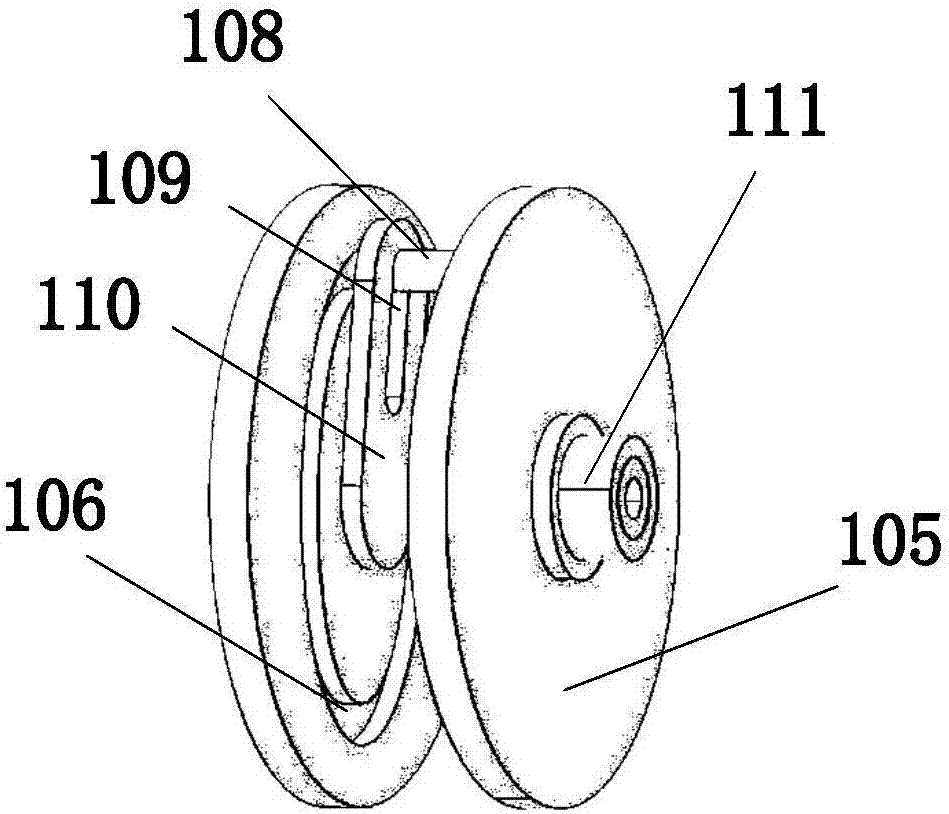

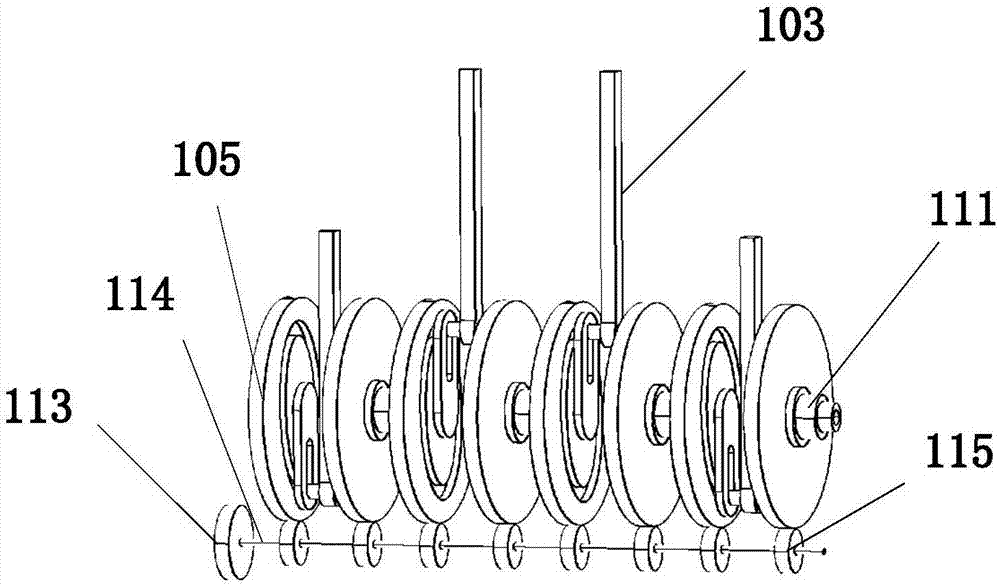

Embodiment 1

[0058] The specific working process of the variable compression ratio engine described in Embodiment 1 is as follows:

[0059] When the engine needs to change the compression ratio, the self-locking motor is controlled to rotate at a certain angle, and the self-locking motor drives the disc gear 105 to rotate at a certain angle through a transmission mechanism after decelerating and increasing twist at a certain gear ratio. After the disc gear 105 rotates a certain angle, the positions of the highest point and the lowest point of the elliptical groove 106 on the disc gear change accordingly, thereby changing the positions of the top dead center and the bottom dead center of the engine piston 102 to achieve a change in engine compression. than the purpose. When the highest point and the lowest point of the elliptical groove 106 on the disk gear 105 are on the long axis of the ellipse, the piston stroke is the largest, the volume of the combustion chamber is the smallest, the en...

Embodiment 2

[0065] The specific working process of the variable compression ratio engine described in Embodiment 2 is as follows:

[0066] When the engine needs to change the compression ratio, the control actuator drives the transmission shaft 217 to rotate a certain angle, and the transmission shaft drives the disc 205 to move up and down a certain distance through the double-rod mechanism 213 . The top dead center and bottom dead center positions of the piston 202 are determined by the highest and lowest points of the circular groove 206 on the disc 205. When the disc 205 moves up and down for a certain distance, the distance between the top dead center and the bottom dead center of the piston changes accordingly. Since the diameter of the circular groove 206 on the disk does not change during the up and down movement of the disk 205, the distance between the highest point and the lowest point of the circular groove does not change, so during the up and down movement of the disk, The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com