Sequential control loop for servo motor to drive constant delivery pumps

A servo motor, sequential control technology, applied in pump control, machine/engine, mechanical equipment, etc., can solve the problems of shortening the service life of the hydraulic system, increasing the temperature of the hydraulic transmission system, low energy conversion efficiency, etc., to reduce the heat generation. , The effect of stable operation and not easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

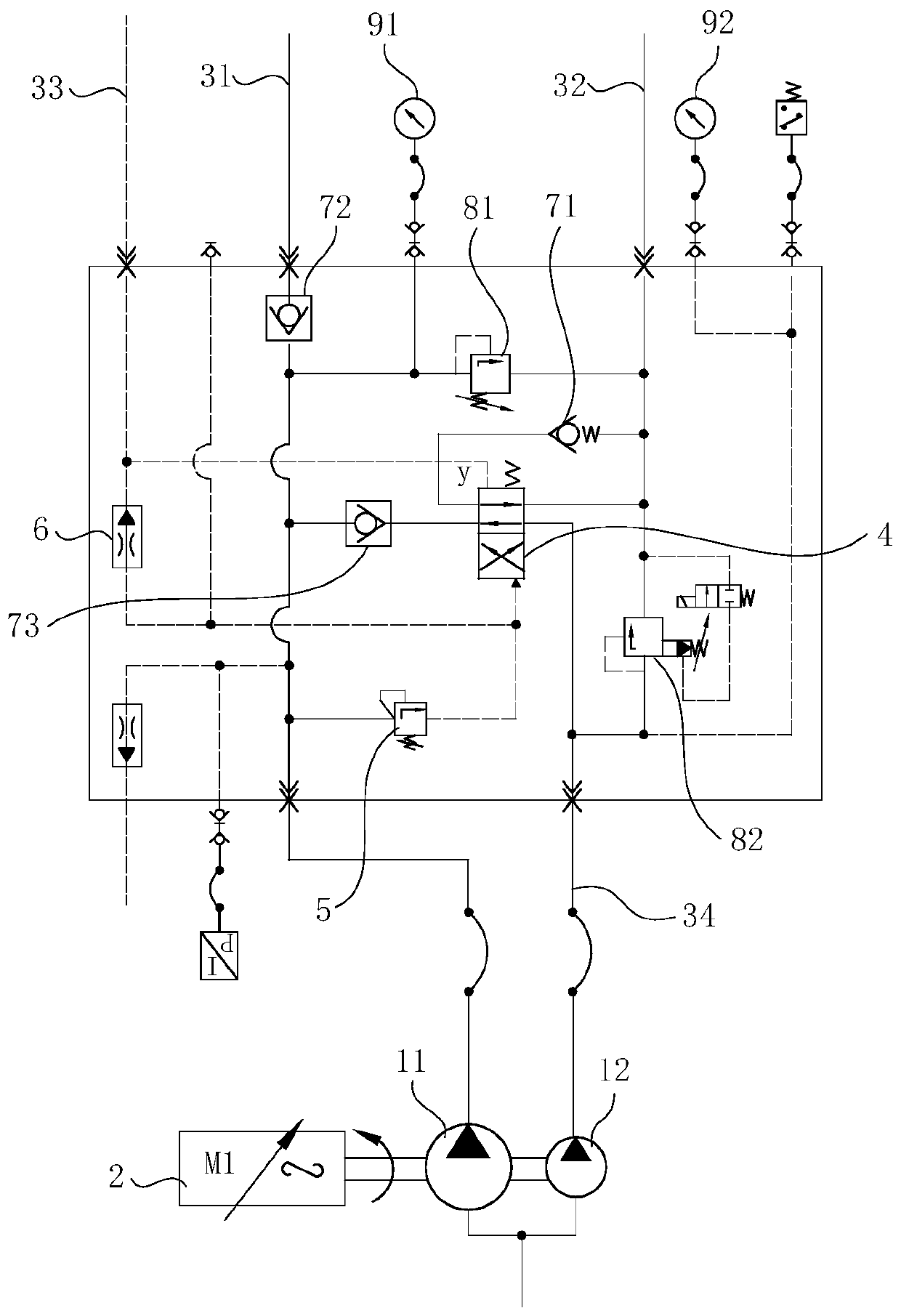

[0024] Such as figure 1 As shown, the sequential control loop for servo motor-driven quantitative pump involved in this embodiment includes servo motor 1, double pump, oil outlet pipeline 31, oil return pipeline 32, oil unloading pipeline 33, branch 34, replacement One-way valve 4, sequence valve 5, damper 6, first one-way valve 71, second one-way valve 72, third one-way valve 73, first relief valve 81, second relief valve 82, first pressure Gauge 91 and second pressure gauge 92.

[0025] Such as figure 1 As shown, the duplex pump is driven by servo motor 1. The duplex pump includes a first quantitative pump 11 and a second quantitative pump 12 coaxially arranged, the oil outlet of the first quantitative pump 11 communicates with the oil outlet pipeline 31, and the oil outlet of the second quantitative pump 12 passes through a branch 34 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com