Controlling the operation of a compressor

A compressor and running time technology, applied in electrical control, mechanical control, engine control, etc., can solve the problem of small running time ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

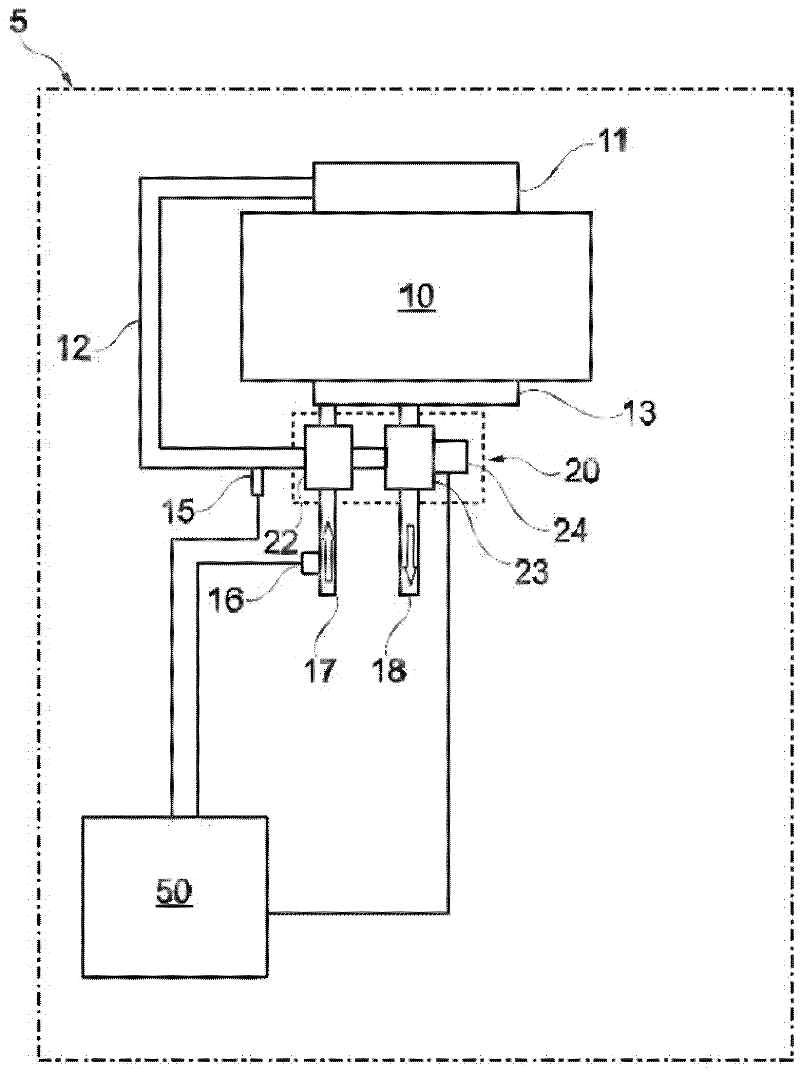

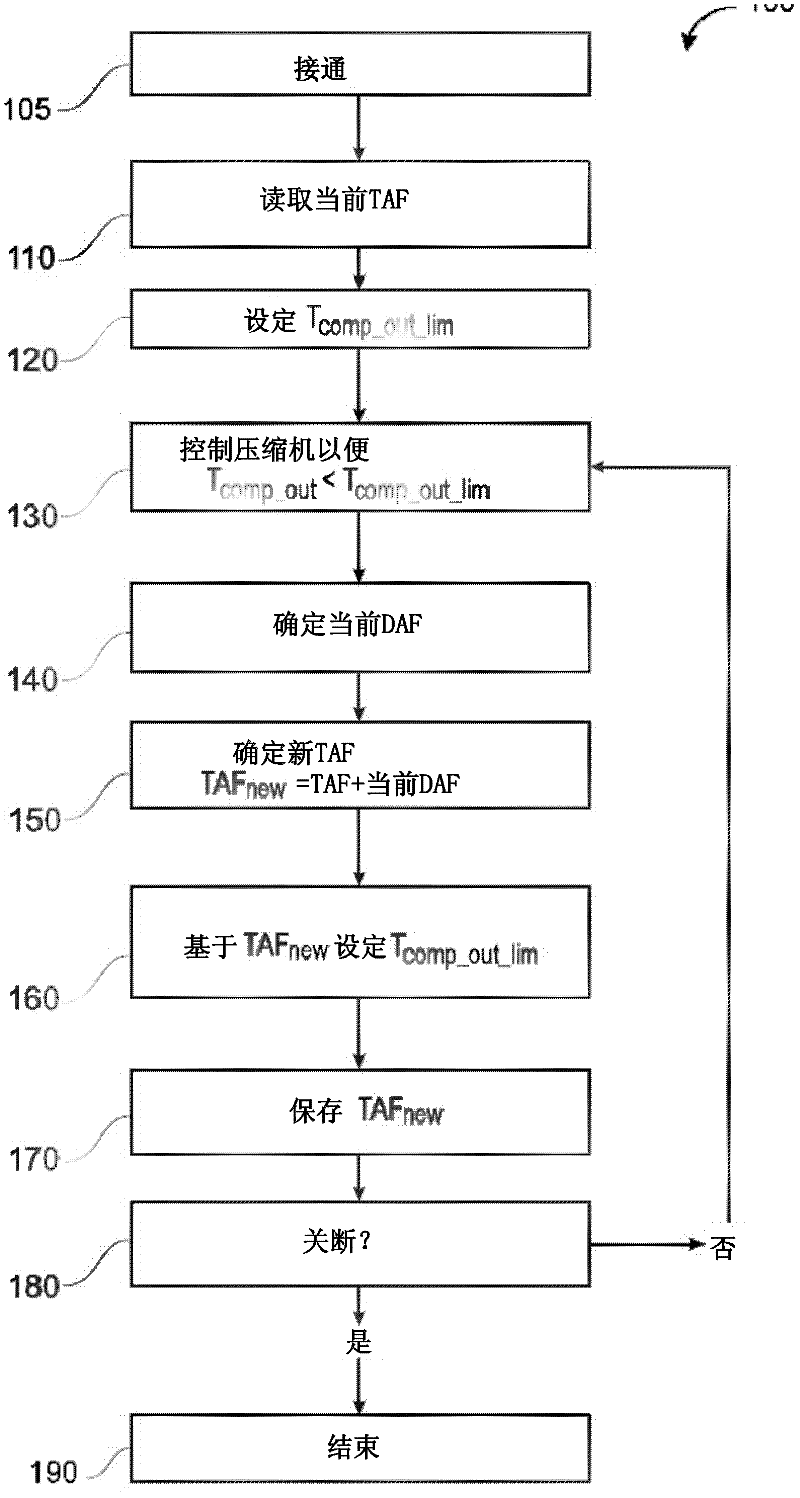

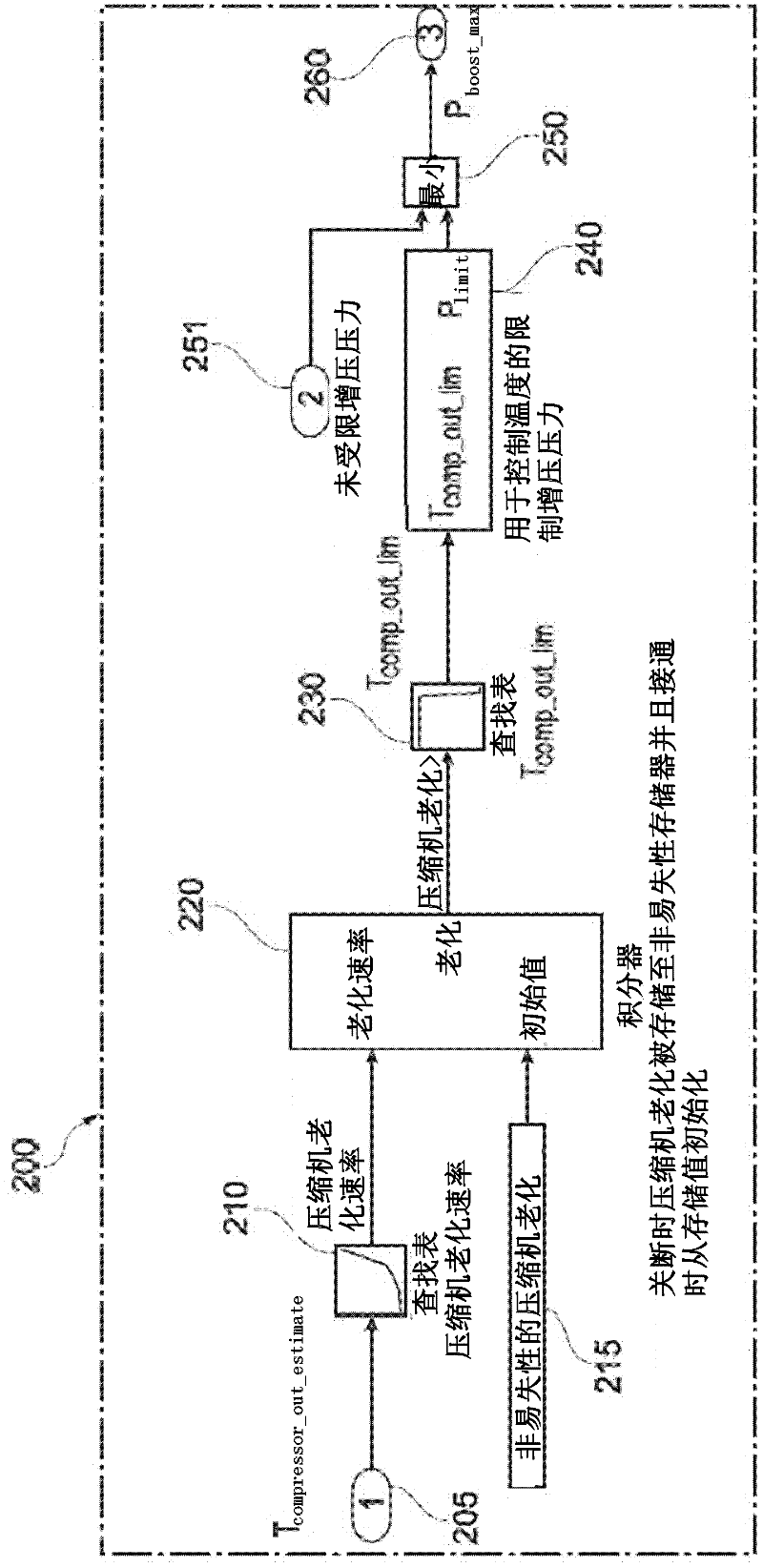

[0017] It is an object of the present disclosure to provide a method of maximizing boosted engine performance. According to a first aspect of the present disclosure there is provided a method for controlling the operation of a compressor arranged to supply charge air to an engine, wherein the method comprises: varying the maximum allowable Compressor outlet temperature, and controlling the operation of the compressor so as not to exceed the maximum allowable compressor outlet temperature.

[0018] The function of compressor temperature and run time may be an overall aging factor indicating the equivalent total run time of the compressor at a predetermined compressor outlet temperature. Changing the maximum allowable compressor outlet temperature may include decreasing the maximum allowable compressor outlet temperature.

[0019] The allowable maximum compressor outlet temperature may be reduced according to a predetermined relationship between the overall aging factor and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com