Method of creating a cosmetic spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

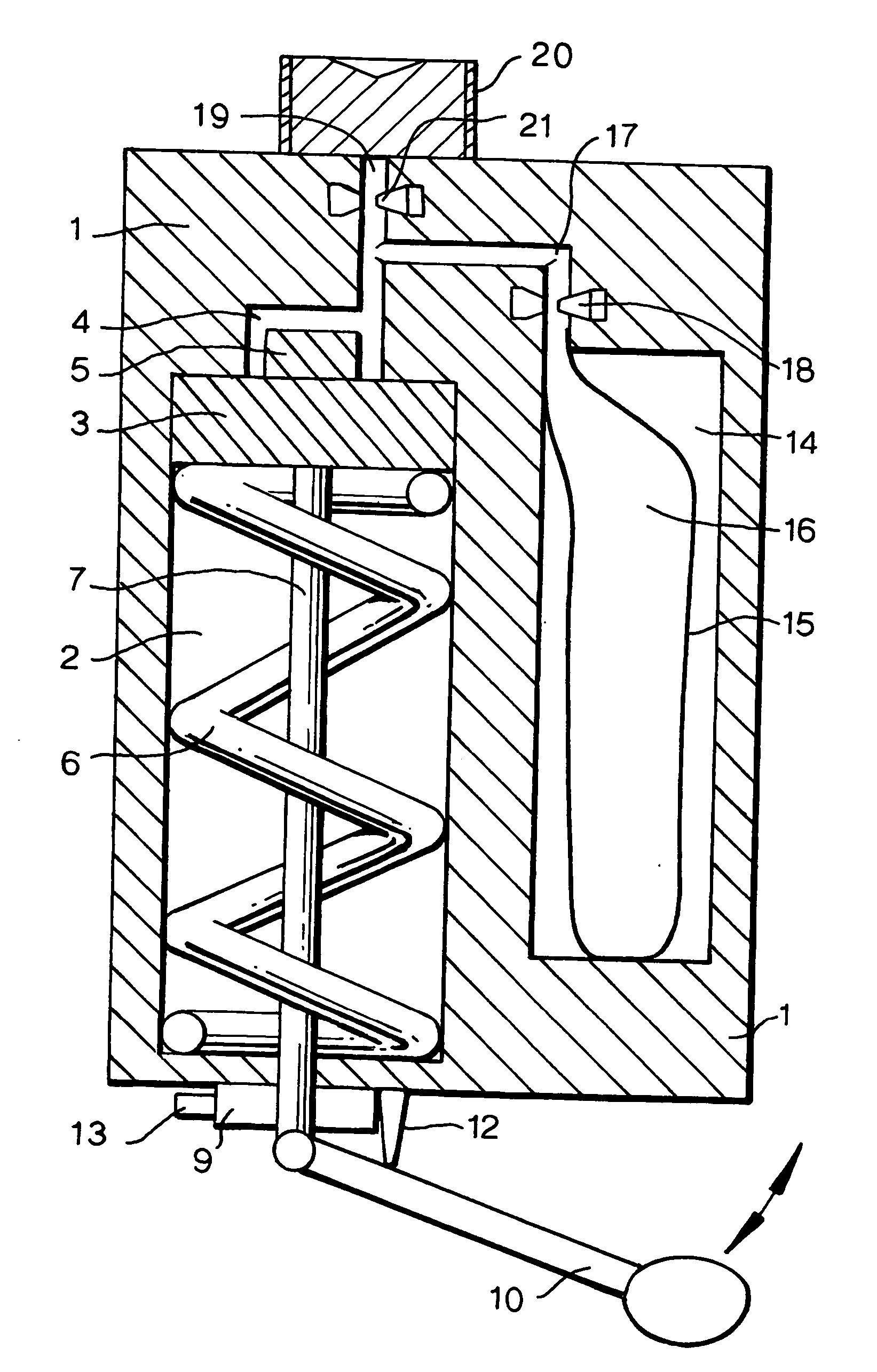

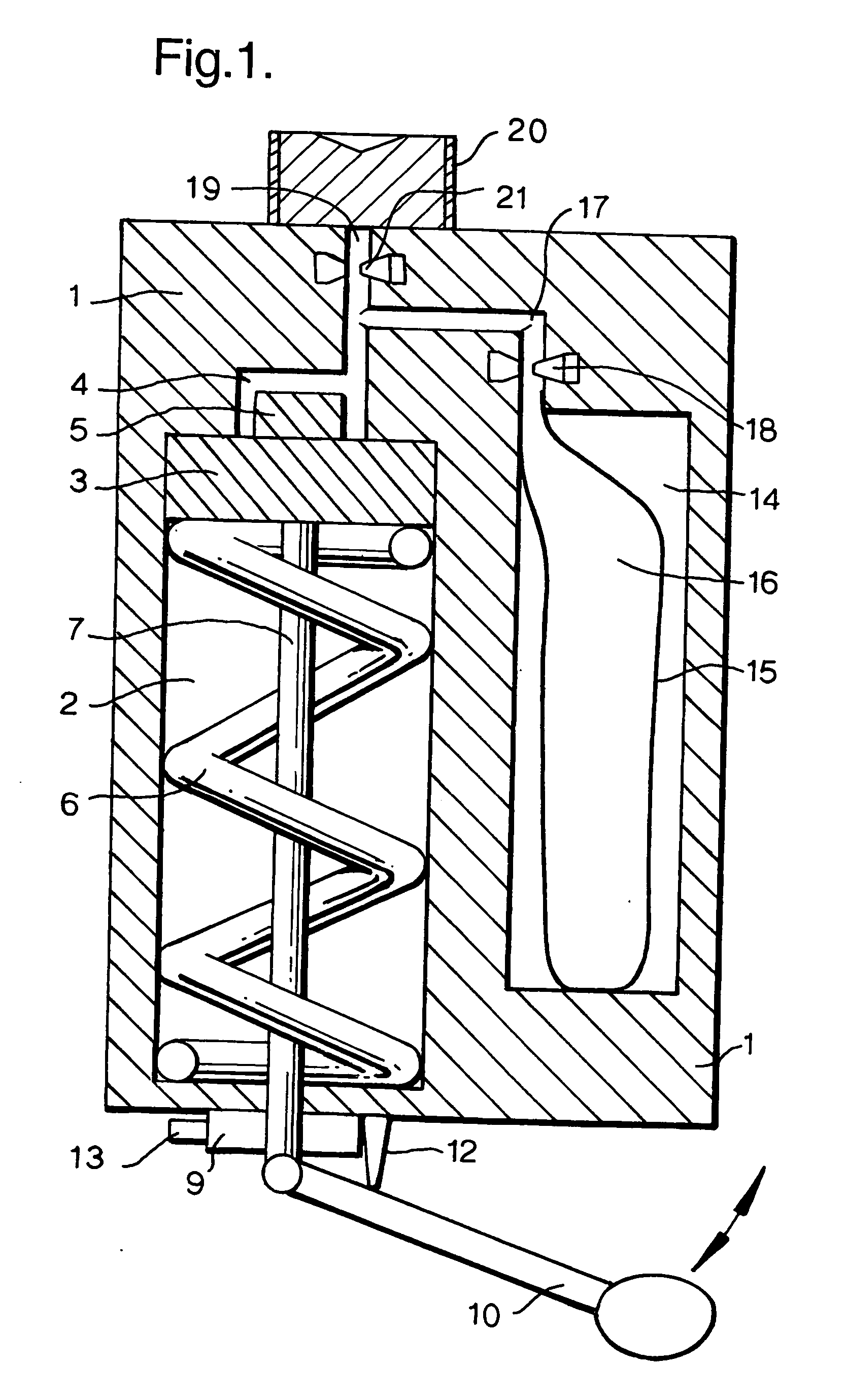

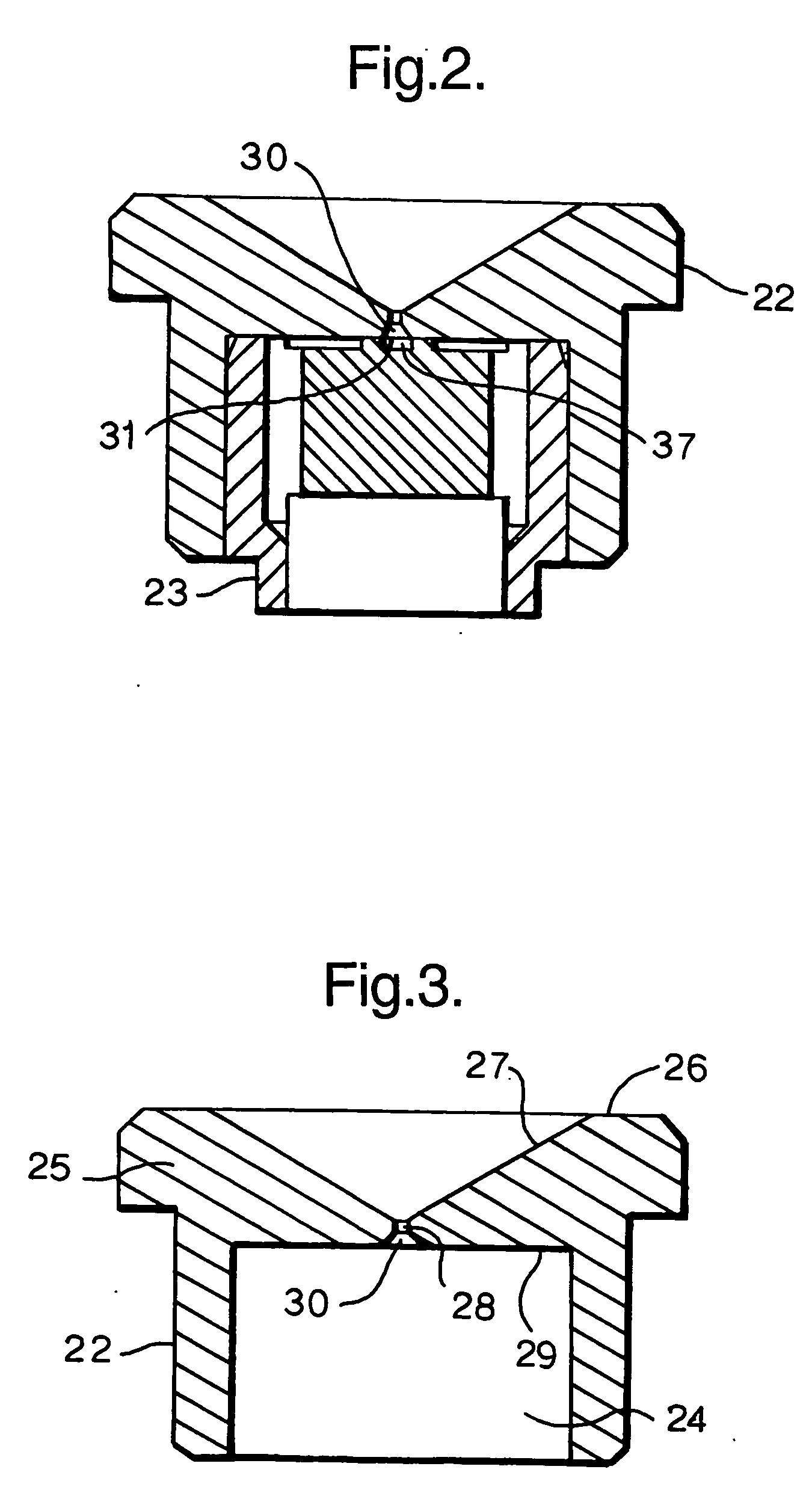

[0041] A series of experiments was performed using the swirl chamber illustrated in FIGS. 2 to 5, using output nozzle sizes of 100, 150, and 200 microns. The following model liquid cosmetic compositions were employed (details in Table 1):

1: deodorant base composition;

2: aqueous-alcohol solution antiperspirant composition;

3: oil-in-water emulsion antiperspirant composition;

[0042] 4: 50 mPa·s standard.

TABLE 1 Model Liquid Cosmetic CompositionsComposition (% w / w)Component1234Ethanol96.0056.50——Isopropyl myristate0.67———Fragrance3.331.50——Reach 501 ACH—36.00——Propylene glycol—3.00——Arlamol E—2.00——DC 245—1.00——Emulgade SE PF——4.50—Emulgin B2——1.00—Cetiol LC——5.00—Cetiol OE——5.00—Water——57.5015Glycerol——2.0085Chlorhydrol——25.00—(50% aqu. solution)

[0043] Each of the liquid compositions was subjecting to the pressures indicated in Table 2 using a G15 DVE Maximator® high pressure pump from Schmidt, Kranz & Co. GmbH. Table 2 shows the spray data on use of the 100 micron nozzle with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com