Engine cylinder head structure

A cylinder and engine technology, which is applied in the field of cylinder end structure devices, can solve the problems such as the inability to fully ensure the operating oil pressure of the variable valve synchronizing mechanism, the layout design constraints, and the increase in the overall length of the engine, so as to reduce the number of parts and reduce the number of parts. The effect of number and flow adequacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

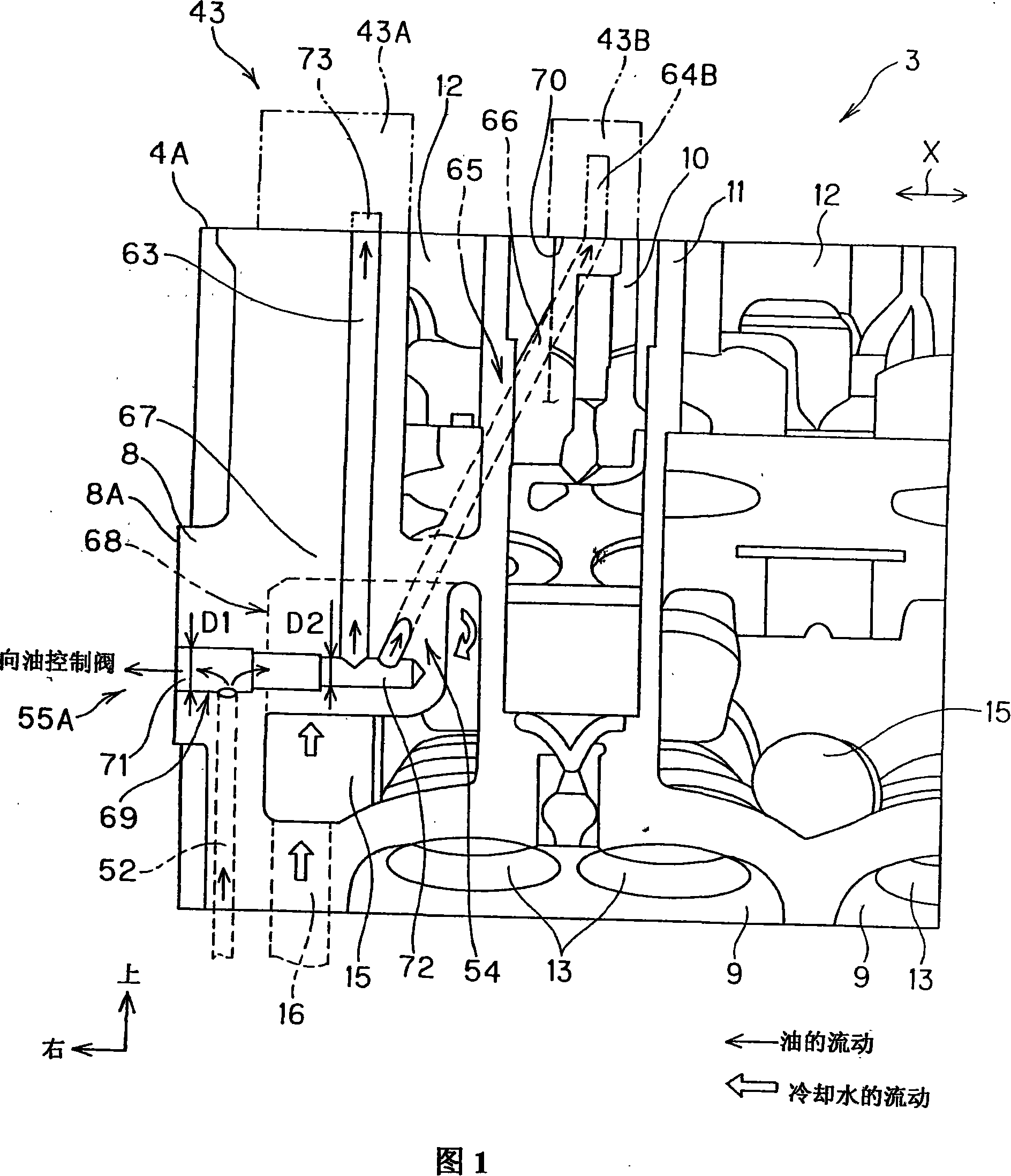

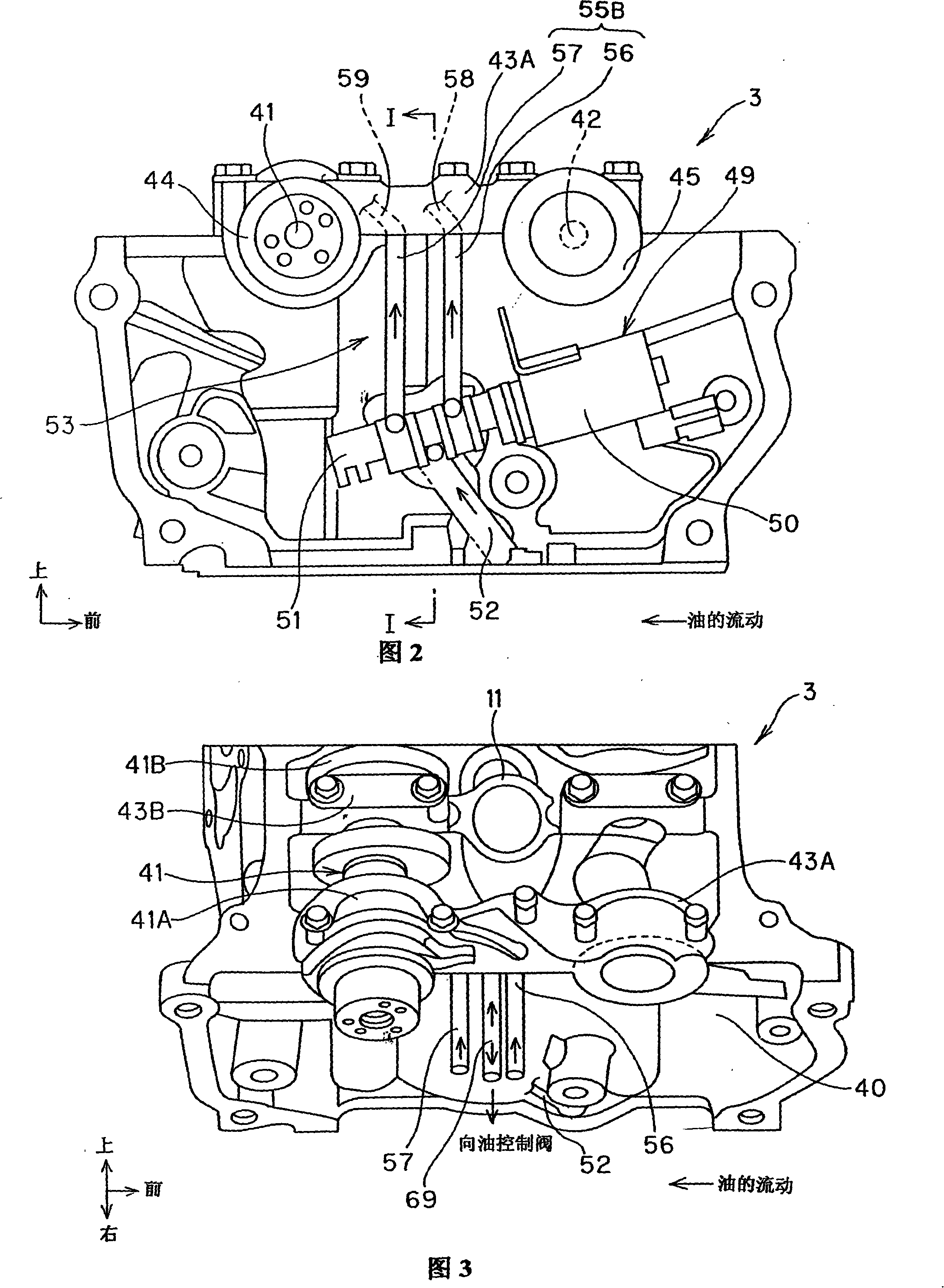

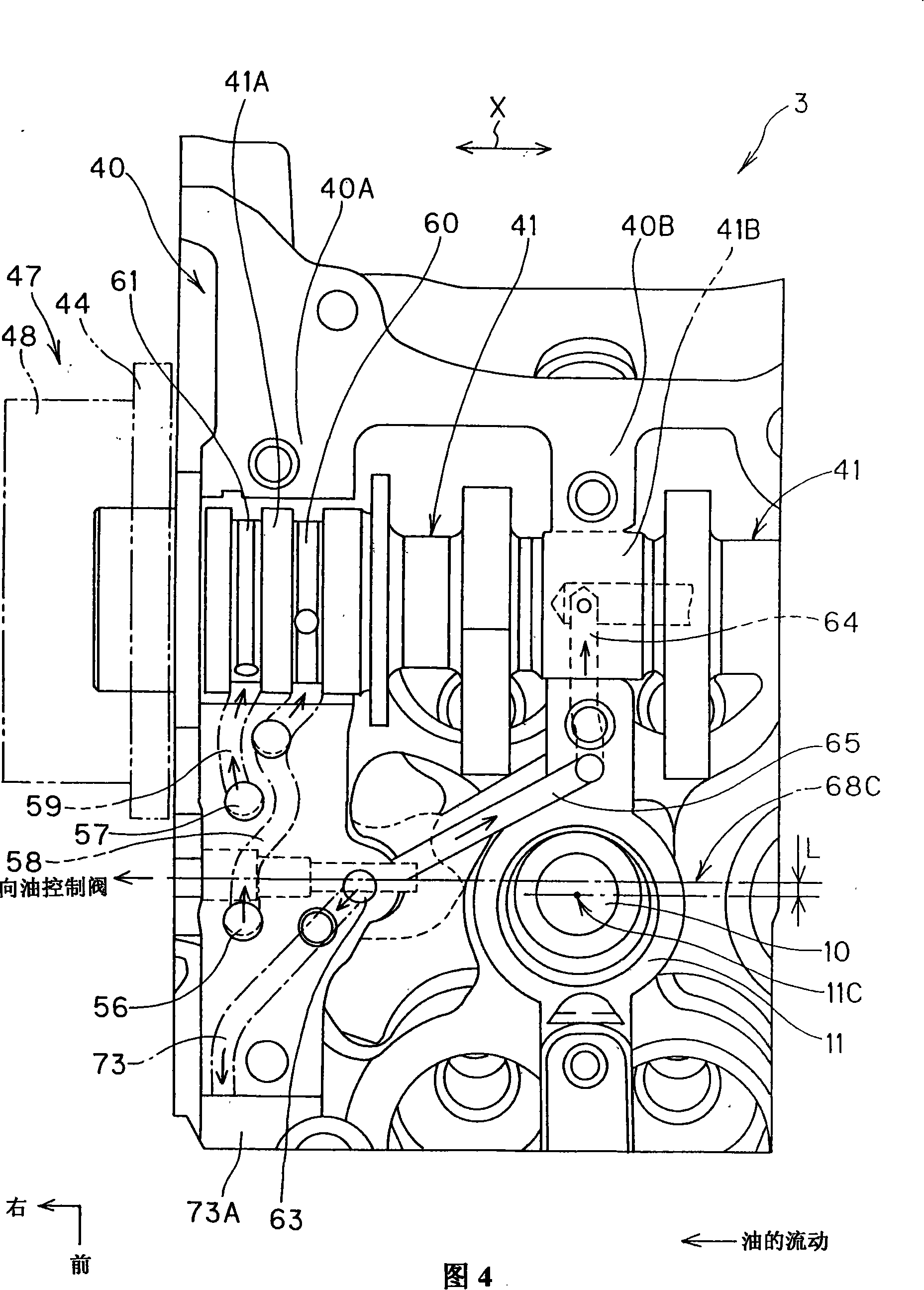

[0027] 1 to 7 show a first embodiment of the present invention. In Fig. 6 and Fig. 7, 1 is a vehicle-mounted multi-cylinder engine. The structure of this engine 1 is such that it is installed horizontally, and includes a cylinder block 2, a cylinder end 3, a cylinder end cover 4, and an oil pan 5, and is installed across the right sides of the cylinder block 2 and the cylinder end 3 to form a chain chamber. 6 for sprocket case 7. As shown in FIG. 1 , this sprocket case 7 is connected and mounted to the connection surface 8A of the end wall 8 of the cylinder end 3 .

[0028] As shown in Figure 1, on the cylinder end 3, corresponding to each cylinder, while the combustion chamber 9 is formed in the lower part, the spark plug hole wall 11 forming the spark plug hole 10 is formed in the upper part and the dynamic cylinder is formed around the spark plug hole wall 11. Valve chamber 12.

[0029] In addition, as shown in FIG. 5 , on the cylinder end 3 , corresponding to each cylin...

Embodiment 2

[0088] Fig. 8 shows a second embodiment of the present invention.

[0089] In the second embodiment, parts having the same functions as those in the above-mentioned first embodiment are denoted by the same symbols.

[0090] The features of the second embodiment are as follows. That is, on the end wall 8 of the cylinder end 3, while forming the branch oil pipe 81 communicating with the head side oil pipe 52 and guiding the oil to the oil control valve 49 side, a cam is formed on this branch oil pipe 81. The bearing oil groove 82 is further formed with a cam bearing oil pipe 83 communicating with the cam bearing oil groove 82 . The cam bearing groove 82 has a predetermined pipe area with a pipe width W, and functions as a regulating valve that restricts the amount of oil required for lubricating the camshaft. In addition, the cam bearing oil pipe 83 is formed inside the water jacket 15 of the cylinder head 3 .

[0091] In addition, on the end wall 8 of the cylinder end 3, a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com