Device and technology for continuously producing 2,2-dimethylolbutanoic acid

A dimethylol butyric acid and process technology, applied in the field of continuous production of 2,2-dimethylol butyric acid, can solve the problems of poor control of the production process, serious pollutant discharge, and poor process optimization, and achieve Reduce the labor intensity of workers, improve production safety, and improve the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

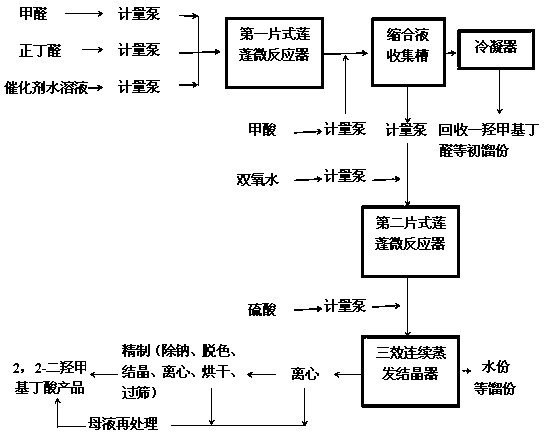

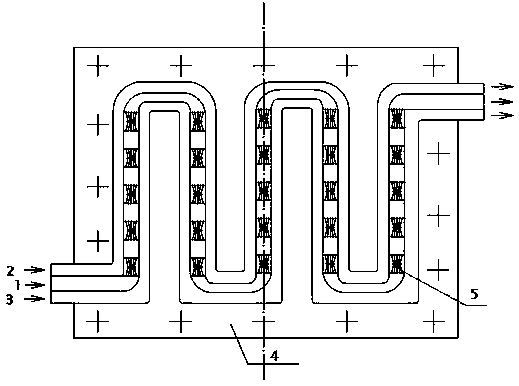

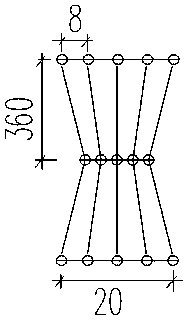

[0037] A process and device for continuous production of 2,2-dimethylolbutyric acid using chip-type shower microreactors. The catalyst aqueous solution, n-butyraldehyde, and formaldehyde are each pumped into the chip-type shower with a booster metering pump according to the designed flow rate. The microreactor performs continuous condensation reaction.

[0038] The first piece shower microreactor for condensation is composed of 5 groups of piece shower microreactors connected in parallel. The flow rate of each solution is 1m / s, and the flow rate of the catalyst is Q 催化剂 =483.30L / h; the flow Q of formaldehyde 甲醛 =433.40L / h; the flow Q of n-butyraldehyde 正丁醛 =209.00 L / h. The flow rate of formic acid is Q 甲酸 =14.80L / h; control the condensation temperature to 60°C. The condensed liquid (dimethylolbutyraldehyde) and hydrogen peroxide left in the collection tank are pumped into the continuous sheet-type shower microreactor with a booster metering pump to carry out continuous oxi...

Embodiment 2

[0041] The first chip shower microreactor for condensation is composed of 5 groups of chip shower microreactors connected in parallel. The flow rate of each solution is 0.3m / s, and the flow rate of the catalyst is Q 催化剂 =145.00L / h; the flow Q of formaldehyde 甲醛 =130.00L / h; the flow Q of n-butyraldehyde 正丁醛 = 62.70 L / h. The flow rate of formic acid is Q 甲酸 =4.50L / h; control the condensation temperature to 70°C. The condensed liquid (dimethylolbutyraldehyde) and hydrogen peroxide left in the collection tank are pumped into the continuous sheet-type shower microreactor with a booster metering pump to carry out continuous oxidation reaction.

[0042] The second sheet-type shower microreactor for oxidation is composed of 7 groups of sheet-type shower micro-reactors connected in parallel. The flow rate of the two solutions is 0.3m / s, and the flow rate of the condensation liquid is Q 缩合液 =332.55L / h; flow Q of hydrogen peroxide 双氧水 =72.11L / h; the content of hydrogen peroxide is 3...

Embodiment 3

[0044] The first piece shower microreactor for condensation is composed of 5 groups of piece shower microreactors connected in parallel. The flow rate of each solution is 0.6m / s, and the flow rate of the catalyst is Q 催化剂 =290.00L / h; the flow Q of formaldehyde 甲醛 =260.00L / h; the flow Q of n-butyraldehyde 正丁醛 =125.40 L / h. The flow rate of formic acid is Q 甲酸 =9.00L / h; control the condensation temperature to be 80°C. The condensed liquid (dimethylolbutyraldehyde) and hydrogen peroxide left in the collection tank are pumped into the continuous sheet-type shower microreactor with a booster metering pump to carry out continuous oxidation reaction.

[0045] The second chip shower microreactor for oxidation is composed of 8 groups of chip shower microreactors connected in parallel. The flow rate of the two solutions is 0.6m / s, and the flow rate Q of the condensation liquid is 缩合液 =665.10L / h; flow Q of hydrogen peroxide 双氧水 =144.20L / h; the content of hydrogen peroxide is 35%, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com