Oil agent for carbon fiber precursor fiber, carbon fiber and method for producing carbon fiber

A technology of carbon fiber precursors and fibers, which is applied in the fields of fiber chemical characteristics, synthetic polymer artificial filament chemical post-treatment, textiles and papermaking, etc. It can solve problems such as hindering oxygen, hindering productivity, yarn breakage or fluffing, etc., and achieve heat suppression Adhesion and adhesion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Examples of the preparation method of the liquid fine particles used in the oil agent of this embodiment include a method of emulsifying a liquid with a high kinematic viscosity such as the above-mentioned silicone oil with a dispersant, a method of obtaining liquid fine particles by emulsion polymerization of silicone oil, and the like. An organic solvent may be used as the dispersant, but water is preferably used from the viewpoint of imparting uniformity to the precursor fibers and ease of imparting.

[0029] When using water as a dispersant, it is preferable to use a surfactant in combination. The type of surfactant is not particularly limited, and any of anionic, cationic, nonionic, and amphoteric surfactants can be used. In addition to combinations of anionic surfactants and cationic surfactants, the above-mentioned substances can also be used in combination. Among them, cationic surfactants are preferable, weak cationic surfactants containing amino groups and th...

Embodiment 1

[0124] Prepare the carbon fiber precursor oil of the following formulation.

[0125] Amino-modified silicon 66 parts by weight

[0126] Alicyclic epoxy modified silicon 28 parts by weight

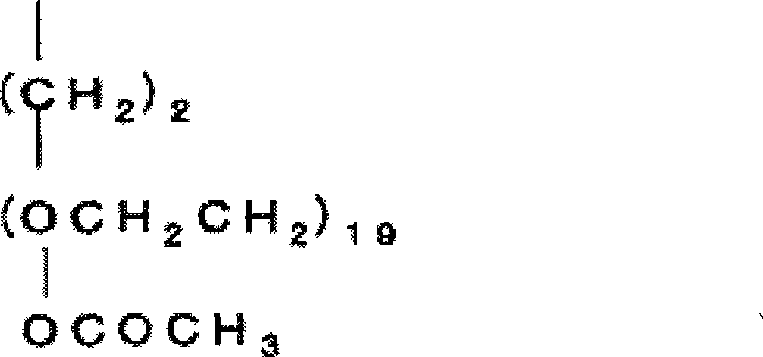

[0127] 5 parts by weight of alkylene oxide modified silicon

[0128] 30 parts by weight of nonionic surfactant

[0129] Water 4000 parts by weight

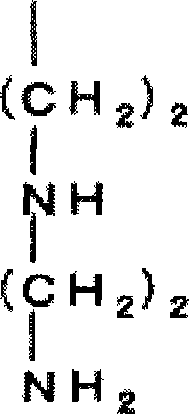

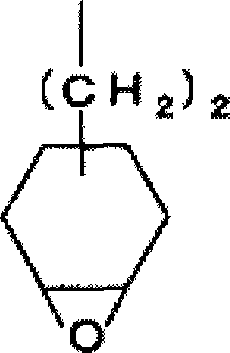

[0130] As the amino-modified silicon, a silicon compound obtained by substituting a part of the side chain of dimethyl silicon with an amino group represented by the following chemical formula 1 was used. The amino equivalent of amino-modified silicon is 2000 mol / g, and the kinematic viscosity at 25° C. is 1000 cSt. As the alicyclic epoxy-modified silicon, a silicon compound obtained by substituting a part of the side chain of dimethyl silicon with an alicyclic epoxy group represented by the following chemical formula 2 was used. The epoxy equivalent of alicyclic epoxy-modified silicon is 6000 mol / g, and the kinematic viscosity at 25° C. i...

Embodiment 2

[0138] Carbon fibers were obtained in the same manner as in Example 1 except that the oil of the following formulation was used instead of the oil for carbon fiber precursors used in Example 1.

[0139] 100 parts by weight of amino-modified silicon

[0140] 30 parts by weight of nonionic surfactant

[0141] Water 4000 parts by weight

[0142] As the amino-modified silicon, a silicon compound obtained by substituting a part of the side chain of dimethyl silicon with an amino group represented by the following chemical formula 1 was used. The amino equivalent of the amino-modified silicon is 2000mol / g, and the kinematic viscosity at 25°C is 3500cSt. Add the above-mentioned silicon, surfactant and water, and use a homomixer and a homogenizer to prepare an emulsion. KM902 (manufactured by Shin-Etsu Chemical Co., Ltd.) was added to the emulsion and stirred to obtain an oil preparation.

[0143] During the production of the carbon fibers, significant fuzzing and cutting which wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com