Thermal transfer sheet

A thermal transfer sheet and transfer layer technology, which is applied in printing, printing devices, and post-processing of printing, can solve the problems of inhibiting thermal bonding durability that have not yet been realized, and achieve the goal of inhibiting thermal bonding and improving durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

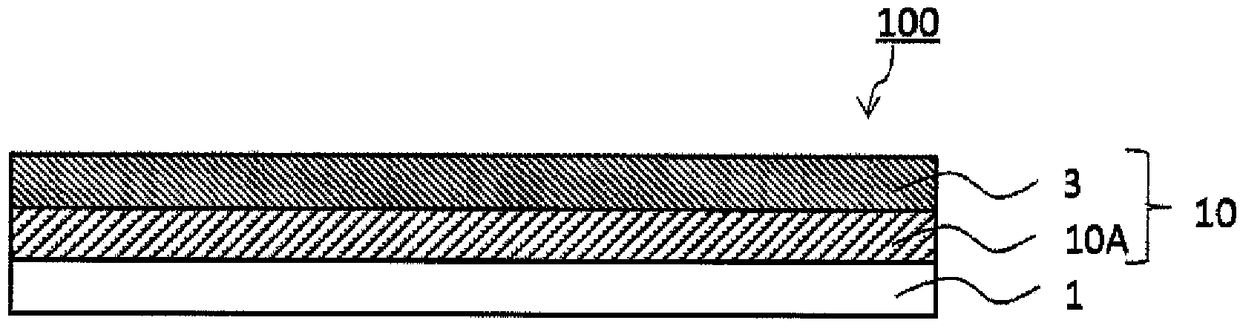

[0084] Using a polyethylene terephthalate film (Toray Co., Ltd.) with a thickness of 4.5 μm as a substrate, coating liquid 1 for a base layer of the following composition was applied to one surface of the substrate, and dried. The thickness is 1 μm, and it is dried to form a base layer. Next, the coating liquid 1 for a protective layer of the following composition was apply|coated on the base layer so that the thickness after drying might be 1 micrometer, and it dried and formed the protective layer. In addition, a coating liquid for a back layer having the following composition was applied to the other surface of the substrate and dried to form a back layer with a thickness of 1 μm after drying, thereby obtaining a substrate with A transfer layer formed by laminating a base layer and a protective layer, and the thermal transfer sheet of Example 1 in which a back layer is provided on the other surface of the base material. In addition, the coating liquid for the base layer 1, ...

Embodiment 2

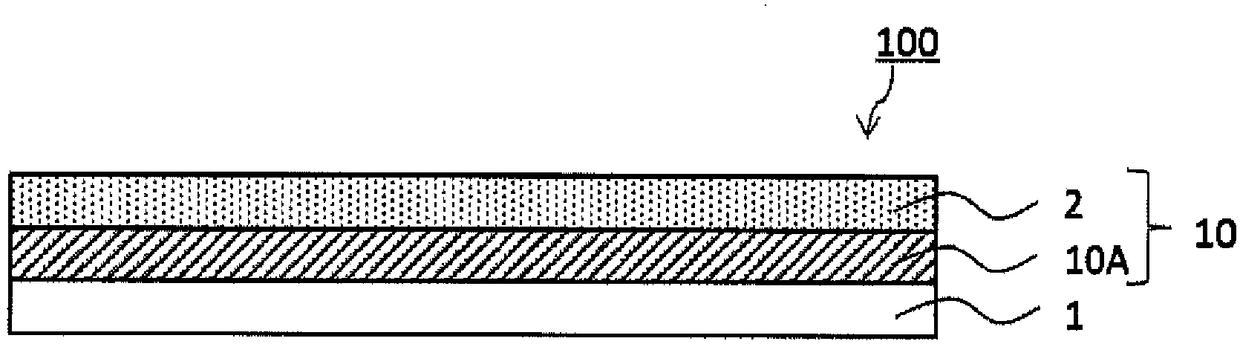

[0105] The coating liquid 1 for the base layer was changed to the coating liquid 2 for the base layer of the following composition to form the base layer, except that everything was carried out in the same manner as in Example 1. The base layer was provided on one surface of the substrate. The transfer layer formed by laminating the base layer and the protective layer, and the thermal transfer sheet of Example 2 in which the back layer is provided on the other surface of the base material.

[0106]

[0107] ·25 parts of copolymer of isobutyl methacrylate and acrylic acid

[0108] (Acid value: 93mgKOH / g, Mw: 12500, Tg: 81°C)

[0109] ·67 parts of methyl ethyl ketone

[0110] · 8 parts of n-propyl acetate

Embodiment 3

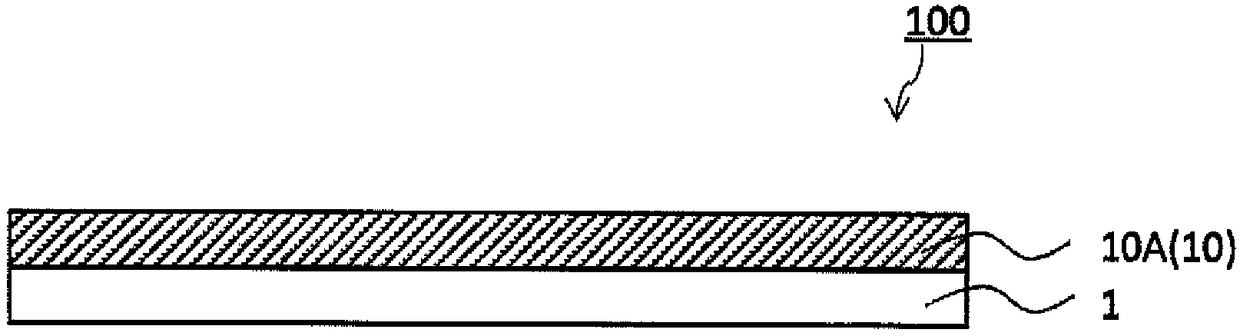

[0112] The coating liquid 1 for the base layer was changed to the coating liquid 3 for the base layer of the following composition to form the base layer, except that everything was carried out in the same manner as in Example 1 to obtain a base on one surface of the substrate. The transfer layer formed by laminating the base layer and the protective layer, and the thermal transfer sheet of Example 3 in which the back layer is provided on the other surface of the base material.

[0113]

[0114] ·25 parts of copolymer of isobutyl methacrylate and acrylic acid

[0115] (Acid value: 49mgKOH / g, Mw: 11400, Tg: 74°C)

[0116] ·67 parts of methyl ethyl ketone

[0117] · 8 parts of n-propyl acetate

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com