Method for assembly and reflow soldering of PCB and FPC and special positioning fixture thereof

A reflow soldering and PCB board technology, which is applied in the direction of assembling printed circuits with electrical components and forming electrical connections of printed components, can solve the problems of cumbersome assembly steps and inconvenient demoulding operations, so as to reduce labor input and ensure product processing Quality, the effect of simplifying the processing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

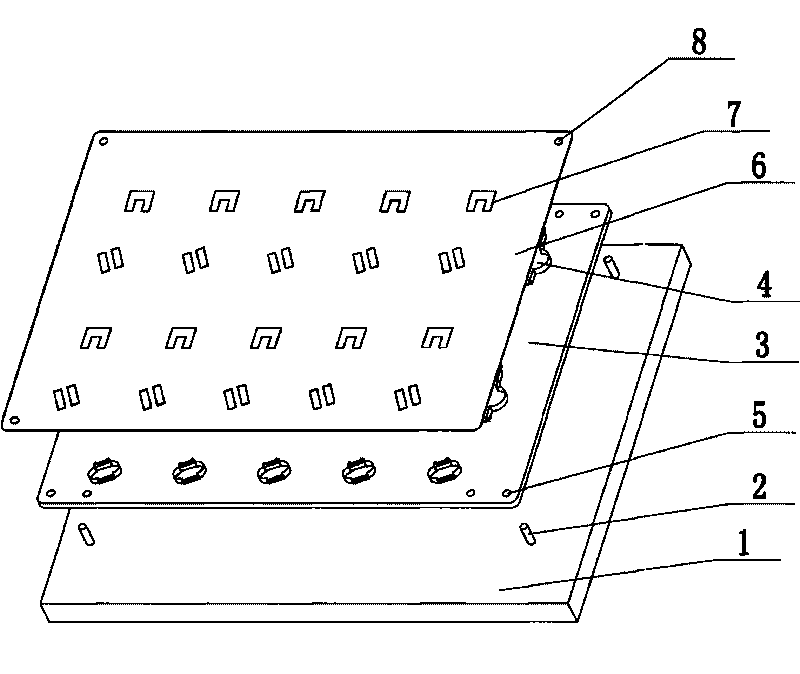

[0020] see figure 2 , the positioning jig 1 used for loading, fixing and positioning PCB and FPC described in this embodiment, the positioning jig 1 is provided with a positioning pin 2, which is an auxiliary in the process of assembling the carrier board 3 and the cover board 6 Fixture, the carrier board 3 can be a hard high temperature resistant aluminum alloy material, the carrier board 3 is processed and formed sinker 4 according to the characteristics of PCB and FPC, and a set of high temperature resistant permanent Magnets, positioning holes 5 are also set on the carrier plate 3, and the cover plate 6 can be processed by a thin plate of ferromagnetic material with elastic deformation. The avoidance hole 7 is set according to the product characteristics, and the positioning hole 8 is set on the cover plate 6 to connect with the carrier plate 3. Positioning hole 5 coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com