Biological method for producing hydrogen by mixing sludge and organic garbage

A technology of organic waste and biological hydrogen production, which is applied in gas production bioreactors, fermentation and other directions, can solve problems such as energy shortage, increase in sludge and organic waste production, achieve considerable environmental and economic benefits, and achieve reduction in weight the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

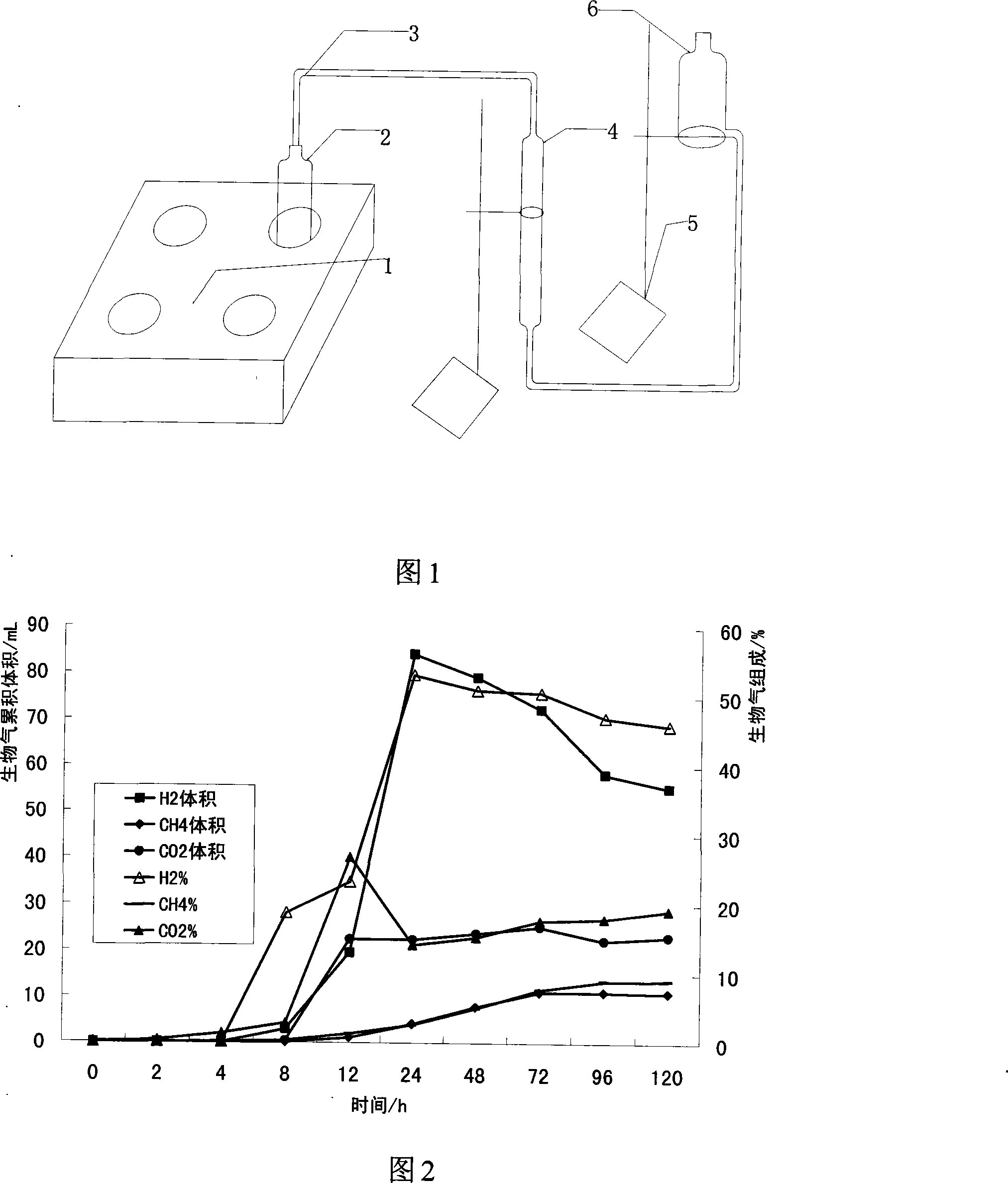

[0019] The test device used in the present invention is shown in Figure 1. The biological hydrogen production reaction device mainly includes a constant temperature water bath 1, a reactor 2, a gas measuring tube 4 and a balance bottle 6. Place the reactor 2 in the constant temperature water bath 1, the outlet of the reactor is connected to one end of the air guide tube 3, the other end of the air guide tube 3 is connected to the measuring air tube 4, and the measuring air tube 4 passes through the air guiding tube and the balance placed on the iron stand 5 Bottle 6 is connected.

[0020] When preparing hydrogen, the test sludge was taken from the sludge dehydration workshop of a sewage treatment plant in Guangdong. According to the percentage of types, its main physical and chemical properties are as follows: moisture content 74.74%, volatile solid content 64.88% (the moisture content of the sludge is The sludge was dried at 105°C, obtained by calculating the ratio of the amo...

Embodiment 2

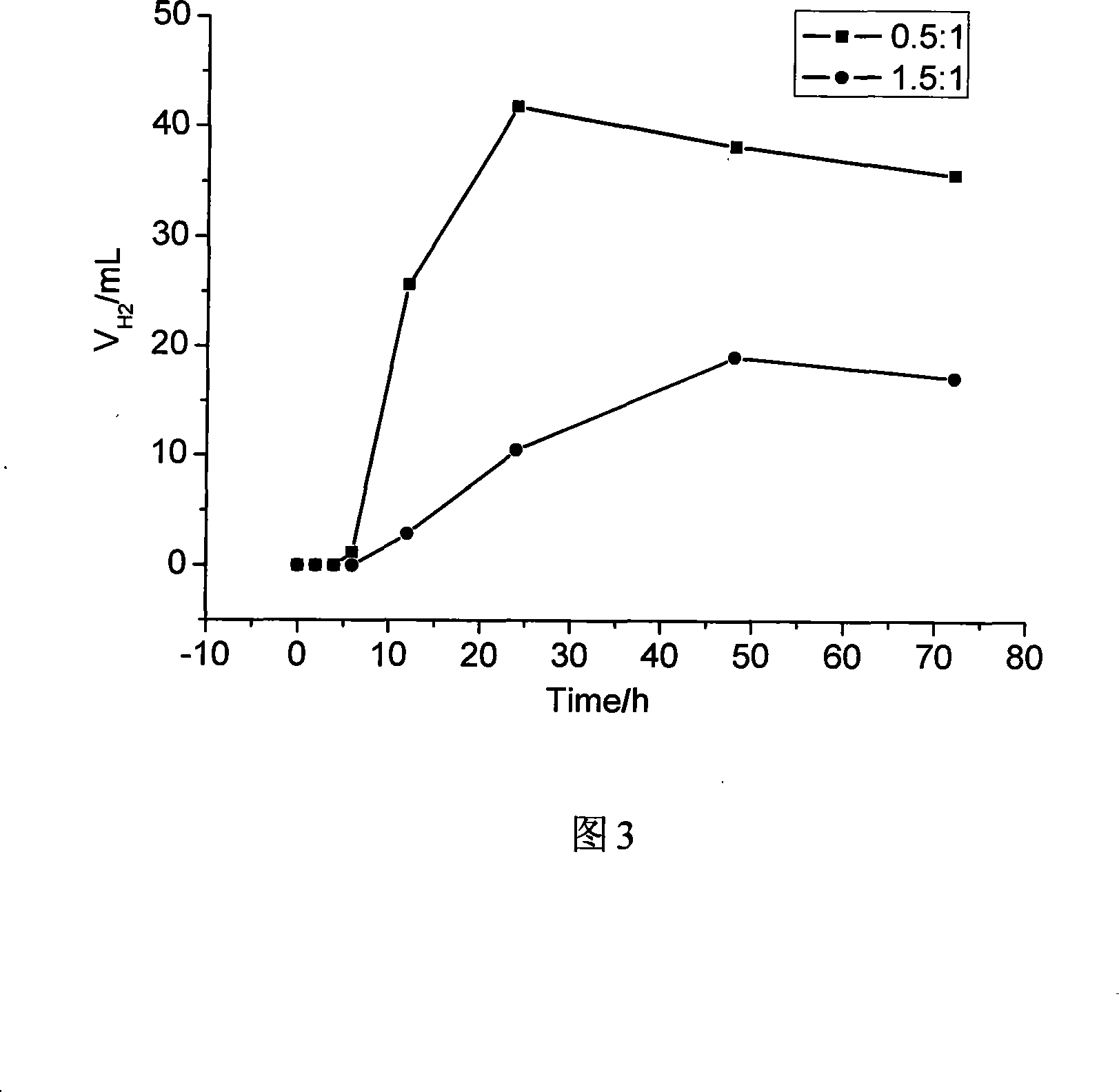

[0022] The test sludge was taken from the sludge dehydration workshop of a sewage treatment plant in Guangdong. According to the percentage of species, its main physical and chemical properties are as follows: moisture content 73.56%, volatile solid content 63.61%, organic waste was taken from a campus vegetable market in Guangdong, Its main features are as follows: moisture content 89.20%, volatile solid content 75.22%. Mix the sludge and organic waste uniformly in a mass ratio of 0.5:1, then add distilled water to dissolve the mixture of sludge and organic waste and adjust its concentration to 40g / L. As shown in Figure 3, the biohydrogen system began to produce hydrogen from the culture time of 6 hours, and the cumulative hydrogen production reached the maximum at 24 hours, which was 41.8 mL.

Embodiment 3

[0024] The test sludge was taken from the sludge dehydration workshop of a paper mill in Guangdong. According to the percentage of species, its main physical and chemical properties are as follows: moisture content 72.42%, volatile solid content 62.57%, organic waste was taken from a campus restaurant in Guangdong, its main characteristics As follows: moisture content 88.31%, volatile solid content 74.58%. Mix the sludge and organic waste uniformly in a mass ratio of 1.5:1, then add distilled water to dissolve the mixture of sludge and organic waste and adjust its concentration to 30g / L. As shown in Figure 3, the biohydrogen system began to produce hydrogen from the incubation time of 12 hours. And the cumulative hydrogen production reached the maximum in 48 hours, which was 19.1 mL. It shows that in an anaerobic environment, the anaerobic biological hydrogen production reactor can successfully realize the mixed fermentation of sludge and organic waste to produce hydrogen, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com