Heat preservation powder negative pressure recycling system in production of refractory material by using fusion casting method

A technology of negative pressure recovery and refractory materials, which is applied in the field of refractory material production, can solve the problems of easy generation of a large amount of dust, hazards to operators, loss of thermal insulation powder, etc., and achieve the effect of no dust pollution, thorough recycling, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

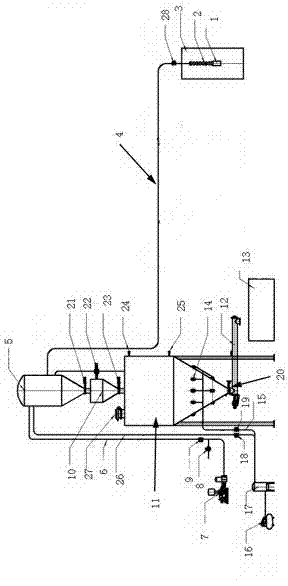

[0025] Such as figure 1 As shown, the thermal insulation powder negative pressure recovery system in the process of producing refractory materials by melting and casting method provided by the present invention includes a material purification system, a negative pressure vacuum system, and a material recovery system.

[0026] The material purification system includes a suction nozzle 1, a flexible connecting pipe 2, a material box 3, a transmission pipeline 4, a dust collector 5, and a baffle valve 28; wherein the suction nozzle 1 and the flexible connecting pipe 2 are located in the material box 3, and the suction nozzle 1 Connect with the dust collector 5 through the flexible connecting pipe 2 and the transmission pipeline 4 in turn; the baffle valve 28 is arranged on the transmission pipeline 4 outside the material box 3;

[0027] The suction nozzle 1 includes an inner tube and an outer tube, and the outer tube moves up and down through an adjusting bolt; thereby adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com