Method of using water-washing filtrate for acidolysis extraction

A filtrate and leaching technology, which is applied in the field of sulfuric acid titanium dioxide production process, can solve the problems that it is difficult to meet the recovery demand of a large amount of washing filtrate, the output of washing filtrate is large, and the recovery cost is high, so as to achieve significant economic and environmental benefits, process optimization, and improvement Effect of Titanium Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

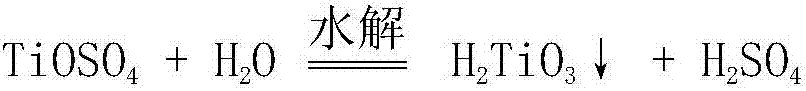

Method used

Image

Examples

Embodiment 1

[0040] Washing filtrate is used to prepare titanyl sulfate solution A according to the following method:

[0041] (1) Take the titanium concentrate powder that has been dried and crushed to a 325-mesh sieve with a residue of 20%, mix it with the titanium concentrate powder with a sulfuric acid solution with a concentration of 70% at an acid-mineral ratio of 1.7, and heat up to 150° C. Acid hydrolysis reaction, until the mixture is solidified, in solid phase.

[0042] (2) The obtained solid phase is aged at 180°C for 4h, and then at 75°C, the sulfuric acid containing 28wt%, the titanium content (as TiO 2 Total) is 57g / L washing filtrate according to 10wt% of clarified water and adds acid hydrolysis pot to leach the material after ripening in order according to 10wt% of clarified water, leaching time 1h, obtains leaching liquid.

[0043] (3) After leaching, add reduced iron powder to the leaching solution for reduction reaction.

[0044] (4) After the reduction reaction is com...

Embodiment 2

[0047] The washing filtrate is used to prepare titanyl sulfate solution B according to the following method:

[0048] (1) Take the titanium concentrate powder that has been dried and crushed to a 325-mesh sieve with a residue of 10%, mix it with the titanium concentrate powder with a sulfuric acid solution with a concentration of 80% at an acid-mineral ratio of 1.3, and heat up to 130° C. Acid hydrolysis reaction, until the mixture is solidified, in solid phase.

[0049] (2) The obtained solid phase is aged at 160°C for 3h, and then at 70°C, the sulfuric acid containing 20wt%, the titanium content (as TiO 2 Total) is 30g / L washing filtrate according to 20wt% of clarified water, add acid hydrolysis pot leaching the material after ripening in sequence, leaching time 3h, obtain leaching solution.

[0050](3) After leaching, add reduced iron powder to the leaching solution for reduction reaction.

[0051] (4) After the reduction reaction is completed, the reducing solution is pu...

Embodiment 3

[0054] The water washing filtrate is used to prepare titanyl sulfate solution C according to the following method:

[0055] (1) Take the titanium concentrate powder that has been dried and crushed to a 325-mesh sieve with a residue of 5%, mix it with the titanium concentrate powder with a sulfuric acid solution with a concentration of 80% at an acid-mineral ratio of 1.0, and heat up to 110° C. Acid hydrolysis reaction, until the mixture is solidified, in solid phase.

[0056] (2) The obtained solid phase is aged at 150°C for 1h, and then at 60°C, the sulfuric acid containing 11wt%, the titanium content (as TiO 2 Total) is 18g / L washing filtrate according to the 50wt% of clarified water and adds acid hydrolysis pot leaching the material after ripening sequentially, leaching time 5h, obtains leaching solution.

[0057] (3) After leaching, add reduced iron powder to the leaching solution for reduction reaction.

[0058] (4) After the reduction reaction is completed, the reducin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com