Method for recycling carbon dioxide based on non-grid-connected wind power

A carbon dioxide and wind power technology, applied in chemical instruments and methods, hydrocarbon production from carbon oxides, hydroxyl compound preparation, etc., can solve the problems of increased carbon dioxide emissions, unstable wind farms, complex control systems, etc. Economic and environmental benefits, the effect of realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

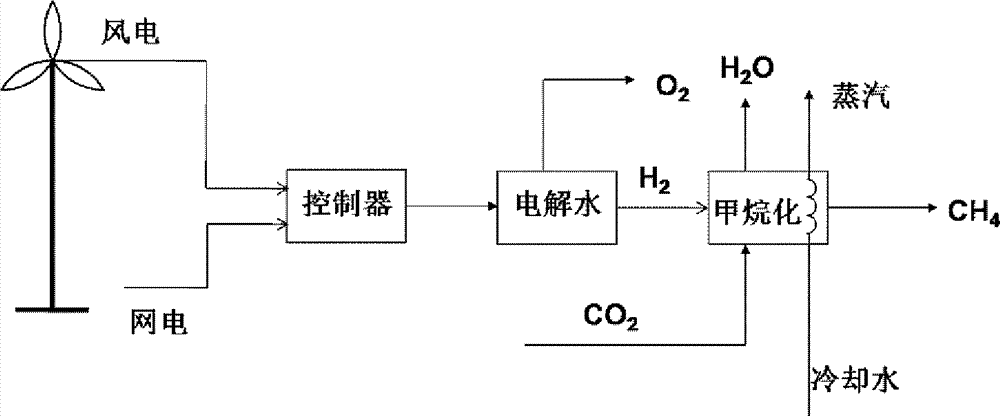

[0019] refer to figure 1 One embodiment of the present invention will be described.

[0020] figure 1 It is a schematic diagram of the system of the present invention

[0021] see figure 1 , taking the production of methane by catalytic reaction as an example, the plant site is selected in an area rich in wind resources, and the wind power enters the controller for simple adjustment to provide electric energy for the electrolysis tank. Cut off the connection with the power grid during the wind power period; electrolyze water to generate hydrogen and oxygen into the hydrogen storage tank and oxygen storage tank respectively; oxygen can be used as an oxidant for oxygen-enriched combustion and coal chemical industry; The carbon dioxide at the rated flow rate of the carbon dioxide storage tank enters the methane reactor for reaction; the heat of the methanation reaction is collected through the waste heat boiler to produce medium-pressure superheated steam, which is partly used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com