Method for treating heavy-metal contaminated acid wastewater

A technology of polluted acid wastewater and treatment method, applied in water/sewage treatment, water/sludge/sewage treatment, gas treatment, etc., can solve the problems of increasing the output of dangerous solid waste, increasing the treatment cost, slowing down the reaction, etc. Significant resource benefits, low-cost treatment, and economic burden reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

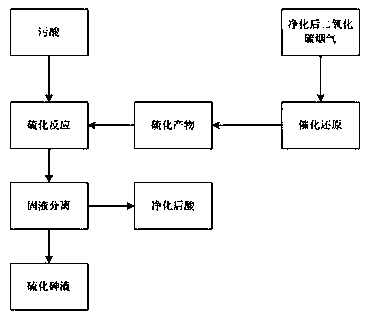

Method used

Image

Examples

Embodiment 1

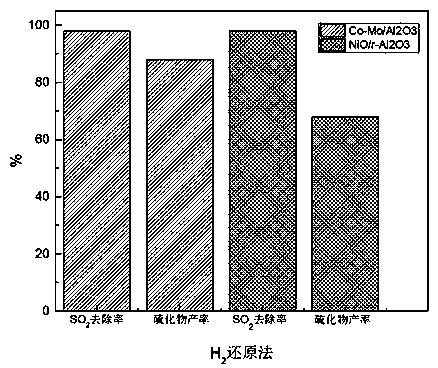

[0026] Using the purified sulfur dioxide flue gas in the lead smelting flue gas acid production process as raw material, using H 2 As reducing agent, Co-Mo / Al 2 o 3 As a catalyst, at a temperature of 300°C, V (H 2 ): V(SO 2 ) = 3 to carry out the catalytic reduction reaction to obtain reduced sulfur products containing hydrogen sulfide and the like. The product hydrogen sulfide is introduced into the polluted acid with arsenic concentration of 10000 mg / L at the introduction amount of 1ml / s to carry out the sulfidation reaction. The oxidation-reduction potential of the sulfidation reaction is 50mV, and the arsenic sulfide slag and heavy metal sulfide slag precipitate obtained after the reaction are filtered and recovered.

[0027] From figure 2 It can be seen that H 2 Reduction method to Co-Mo / Al 2 o 3 When used as a catalyst, SO 2 The removal rate is 98%, and the sulfide yield is 88%, which shows that this method can produce a large amount of sulfide to treat dirty ac...

Embodiment 2

[0031] Using the purified sulfur dioxide flue gas in the pyrite flue gas acid production process as raw material, using H 2 As reducing agent, NiO / r-Al 2 o 3 (r-Al loaded with NiO 2 o 3 ) as the catalyst, at a temperature of 320°C, V(H 2 ): V(SO 2 ) = 2 to carry out catalytic reduction reaction to obtain reduced sulfur products containing hydrogen sulfide and the like. The product hydrogen sulfide is introduced into the polluted acid with arsenic concentration of 9000mg / L at an introduction rate of 1.5ml / s for sulfidation reaction. The oxidation-reduction potential of the sulfidation reaction is controlled to be 20mV, and the arsenic sulfide slag and heavy metal sulfide slag precipitates obtained after the reaction are screened and recovered.

[0032] From figure 2 It can be seen that H 2 Reduction method to NiO / r-Al 2 o 3 When used as a catalyst, SO 2 The removal rate is 98%, and the sulfide yield is 68%, which shows that this method can produce a large amount of s...

Embodiment 3

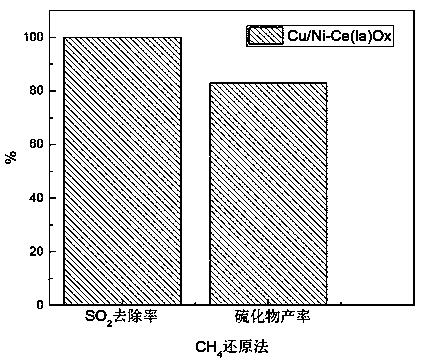

[0036] Using the purified sulfur dioxide flue gas in the copper smelting flue gas acid production process as raw material, CH 4 As a reducing agent, with Cu-doped Ce(La)Ox as a catalyst, at a temperature of 675 °C, V(H 2 ): V(SO 2 ) = 2 to carry out catalytic reduction reaction to obtain reduced sulfur products containing hydrogen sulfide and the like. The product hydrogen sulfide is introduced into the polluted acid with arsenic concentration of 15000mg / L at an introduction amount of 2ml / s for sulfidation reaction. The oxidation-reduction potential of the sulfidation reaction is 60mV, and the arsenic sulfide slag and the heavy metal sulfide slag precipitate obtained after the reaction are filtered and recovered.

[0037] From image 3 It can be seen that CH 4 When the reduction method uses Cu / Ni-Ce(La)Ox as a catalyst, SO 2 The removal rate is 100%, and the sulfide yield is 83%, which shows that this method can produce a large amount of sulfide to treat dirty acid.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com