Novel process for treating industrial wastewater with benzyl alcohol

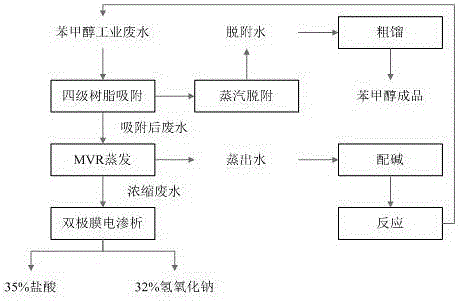

A technology for industrial wastewater and benzyl alcohol, applied in multi-stage water treatment, water/sewage treatment, natural water treatment and other directions, can solve the problems of production system impact, multi-effect evaporation method side reaction, inability to biochemically treat benzyl alcohol wastewater, etc. To achieve the effect of reducing operating costs, saving steam, and achieving significant economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

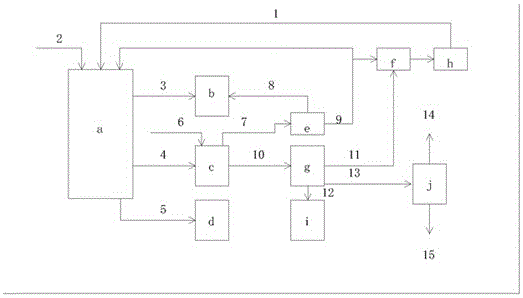

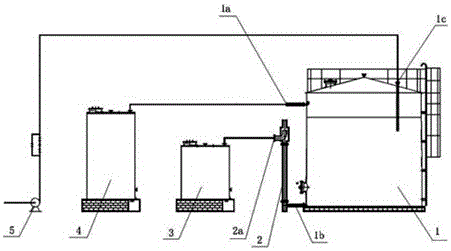

[0028] combine figure 1 , 2 , Shown in 3, novel technique of the present invention comprises the following steps:

[0029] 1) Waste water 1 enters waste water storage tank a, adds flocculant 2, and performs continuous oil-water separation. The upper layer oil phase 3 continuously overflows into the crude distillation tower b, the middle layer water phase 4 is continuously pumped into the resin adsorption tower c, and the lower layer mud 5 according to After settling time, it is withdrawn from the waste water storage tank a, enters the filter press d for pressure filtration, and the filtrate is transferred back to the waste water storage tank a.

[0030] 2) The middle water phase 4 is sequentially pumped into the fourth-stage resin adsorption tower c for adsorption treatment. The adsorption flow rate is generally 1.2bv / h of resin capacity, and the first-stage adsorption tower reaches saturation after 8 hours of adsorption time, and the content of benzyl alcohol in the effluen...

Embodiment 2

[0035] combine figure 1 , 2 , Shown in 3, novel technique of the present invention comprises the following steps:

[0036] 1) Waste water 1 enters waste water storage tank a, adds flocculant 2, and performs continuous oil-water separation. The upper layer oil phase 3 continuously overflows into the crude distillation tower b, the middle layer water phase 4 is continuously pumped into the resin adsorption tower c, and the lower layer mud 5 according to After settling time, it is withdrawn from the waste water storage tank a, enters the filter press d for pressure filtration, and the filtrate is transferred back to the waste water storage tank a.

[0037] 2) The middle water phase 4 is sequentially pumped into the fourth-stage resin adsorption tower c for adsorption treatment. The adsorption flow rate is generally 1.3bv / h of resin capacity, and the first-stage adsorption tower reaches saturation after 10 hours of adsorption time, and the content of benzyl alcohol in the effluent...

Embodiment 3

[0042] combine figure 1 , 2 , Shown in 3, novel technique of the present invention comprises the following steps:

[0043] 1) Waste water 1 enters waste water storage tank a, adds flocculant 2, and performs continuous oil-water separation. The upper layer oil phase 3 continuously overflows into the crude distillation tower b, the middle layer water phase 4 is continuously pumped into the resin adsorption tower c, and the lower layer mud 5 according to After settling time, it is withdrawn from the waste water storage tank a, enters the filter press d for pressure filtration, and the filtrate is transferred back to the waste water storage tank a.

[0044] 2) The middle water phase 4 is sequentially pumped into the fourth-stage resin adsorption tower c for adsorption treatment. The adsorption flow rate is generally 1.5bv / h of resin capacity. Generally, the first-stage adsorption tower reaches saturation after 12 hours of adsorption time, and the content of benzyl alcohol in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com