Method and device for peeling off attachments on surfaces of waste casting sands

A technology of waste sand and binder, which is applied to the cleaning/processing machinery of casting materials, casting molding equipment, metal processing equipment, etc. The effect of economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

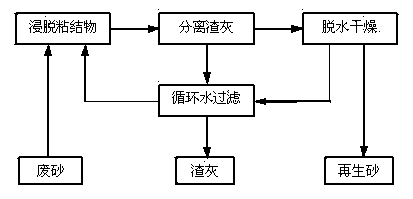

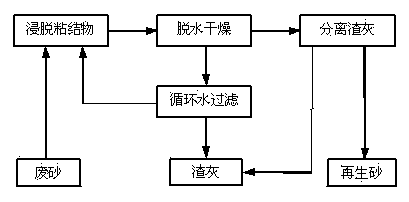

Method used

Image

Examples

Embodiment 1

[0023] Use industrial-grade sodium hydroxide to prepare an aqueous solution with a free alkalinity of 0.1 mol / L, soak the waste sand of alkali phenolic resin, and separate the fallen slag ash with a hydrocyclone, dehydrate the obtained pure sand with a centrifuge, and dry it naturally. According to "Test Methods for Foundry Sand and Mixtures (GB / T 2684)", recycled sand is used to make samples with alkali phenolic resin binder for tensile strength test.

Embodiment 2

[0025] Use industrial-grade potassium hydroxide to prepare an aqueous solution with a free alkalinity of 0.2 mol / L, soak the waste sand of alkali phenolic resin, dehydrate it with a high-frequency vibrating screen, dry the sand with a dryer, and then use wind separation equipment to separate the fallen slag ash . According to "Test Methods for Foundry Sand and Mixtures (GB / T 2684)", recycled sand is used to make samples with alkali phenolic resin binder for tensile strength test.

Embodiment 3

[0027] Use industrial-grade sodium hydroxide to prepare an aqueous solution with a free alkalinity of 0.4 mol / L, soak the waste water glass sand, and separate the fallen slag ash with a hydrocyclone, dehydrate the obtained pure sand with a centrifuge, and dry it naturally. According to "Test Methods for Foundry Sand and Mixtures (GB / T 2684)", recycled sand is used to make samples with modified water glass binder for tensile strength test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com