Treatment process and device of waste gas containing hydrogen sulfide and carbon dioxide

A waste gas treatment device, carbon dioxide technology, applied in the direction of alkali metal sulfide/polysulfide, calcium carbonate/strontium/barium, chemical instruments and methods, etc., can solve the problem of increasing carbon dioxide emissions, adverse environmental effects, and reducing the use of hydrogen sulfide Value and other issues, to achieve the effect of benefit optimization, good economic and environmental benefits, and good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

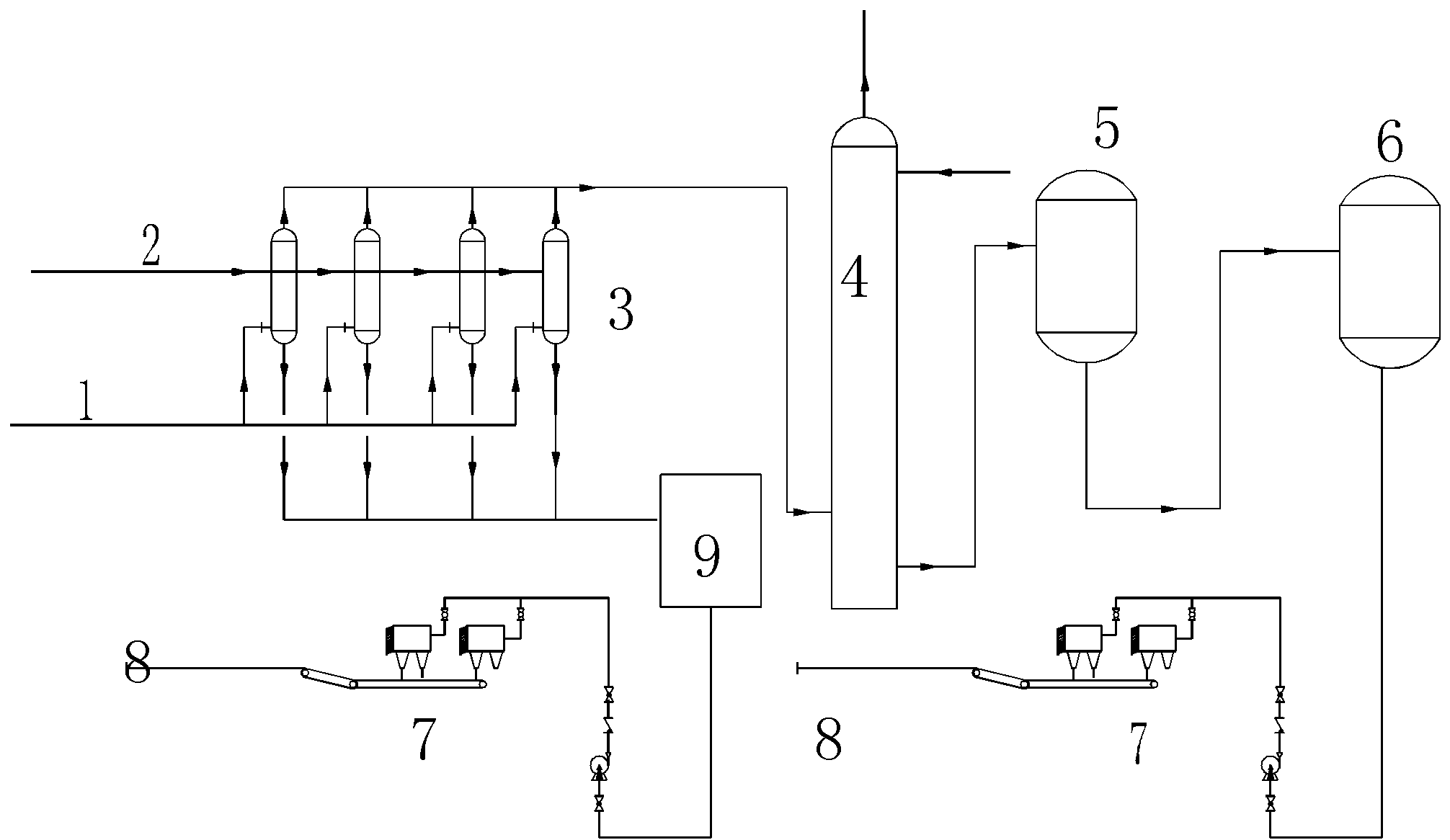

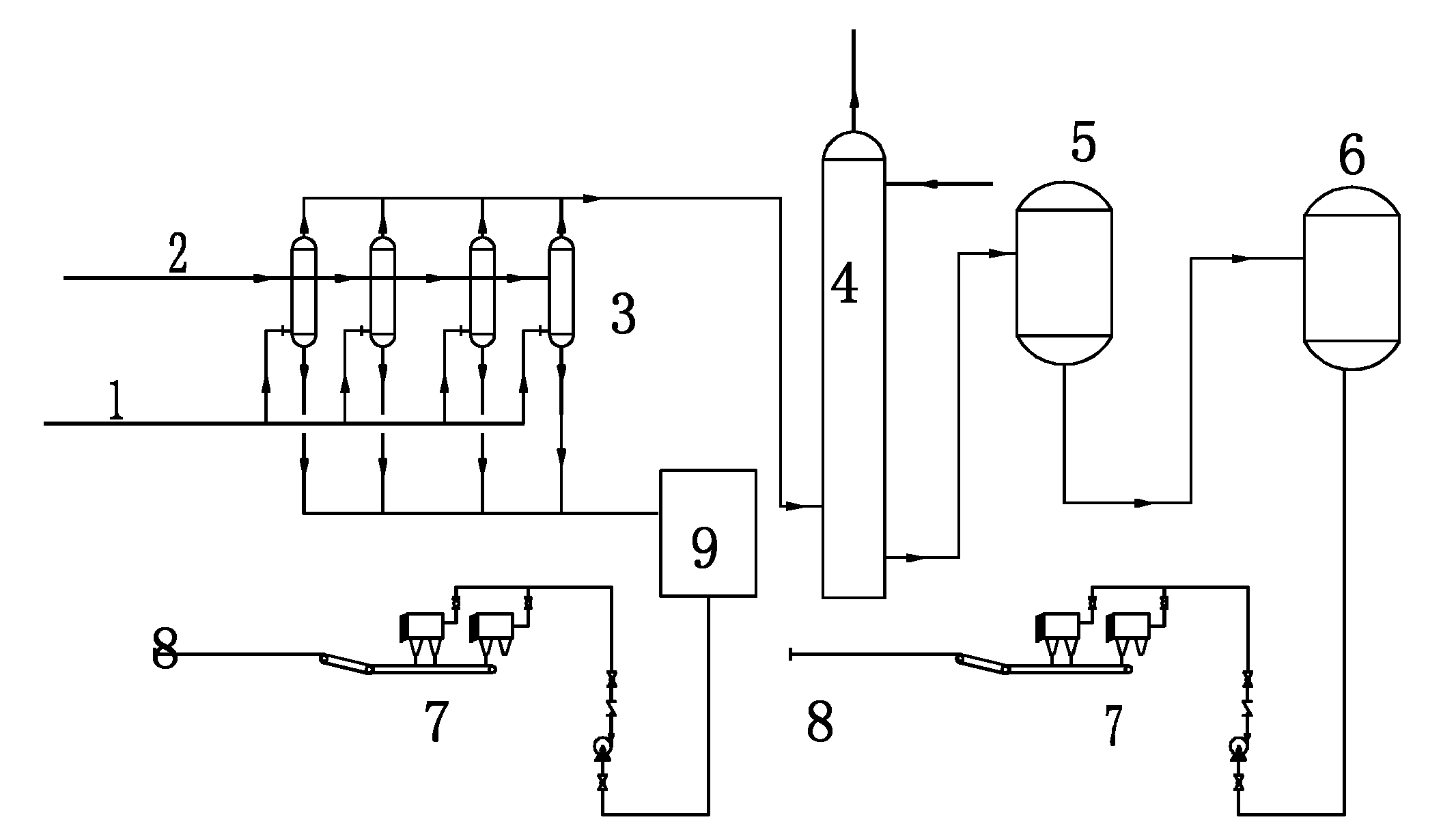

[0014] A waste gas treatment device containing hydrogen sulfide and carbon dioxide, comprising a multi-stage carbon removal tower 3 connected to the waste gas pipe 1, the upper end of the carbon removal tower 3 is connected to an alkali washing tower 4 through a pipeline, and an exhaust port is arranged at the upper end of the alkali washing tower 4, The lower end is connected to the crystallizer 6 through the evaporator 5, and the crystallizer 6 is connected to the centrifuge 7; the lower end of the carbon removal tower 3 is connected to the storage tank 9, and the storage tank 9 is connected to the centrifuge 7. Process flow of waste gas treatment containing hydrogen sulfide and carbon dioxide:

[0015] 1. Processing carbon dioxide to produce barium carbonate

[0016] Use industrial barium sulfate calcined material as raw material, dissolve it in water and stir to separate the solid and liquid, and make a relatively clean 20% barium sulfide solution, mix the carbon dioxide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com