Die for controlling forming of asymmetric complex-curved rebar forge piece by using movable damping block

A complex surface, asymmetric technology, used in the manufacture of tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., can solve problems such as insufficient filling and folding, reduce energy consumption, and promote flow filling. , the effect of good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

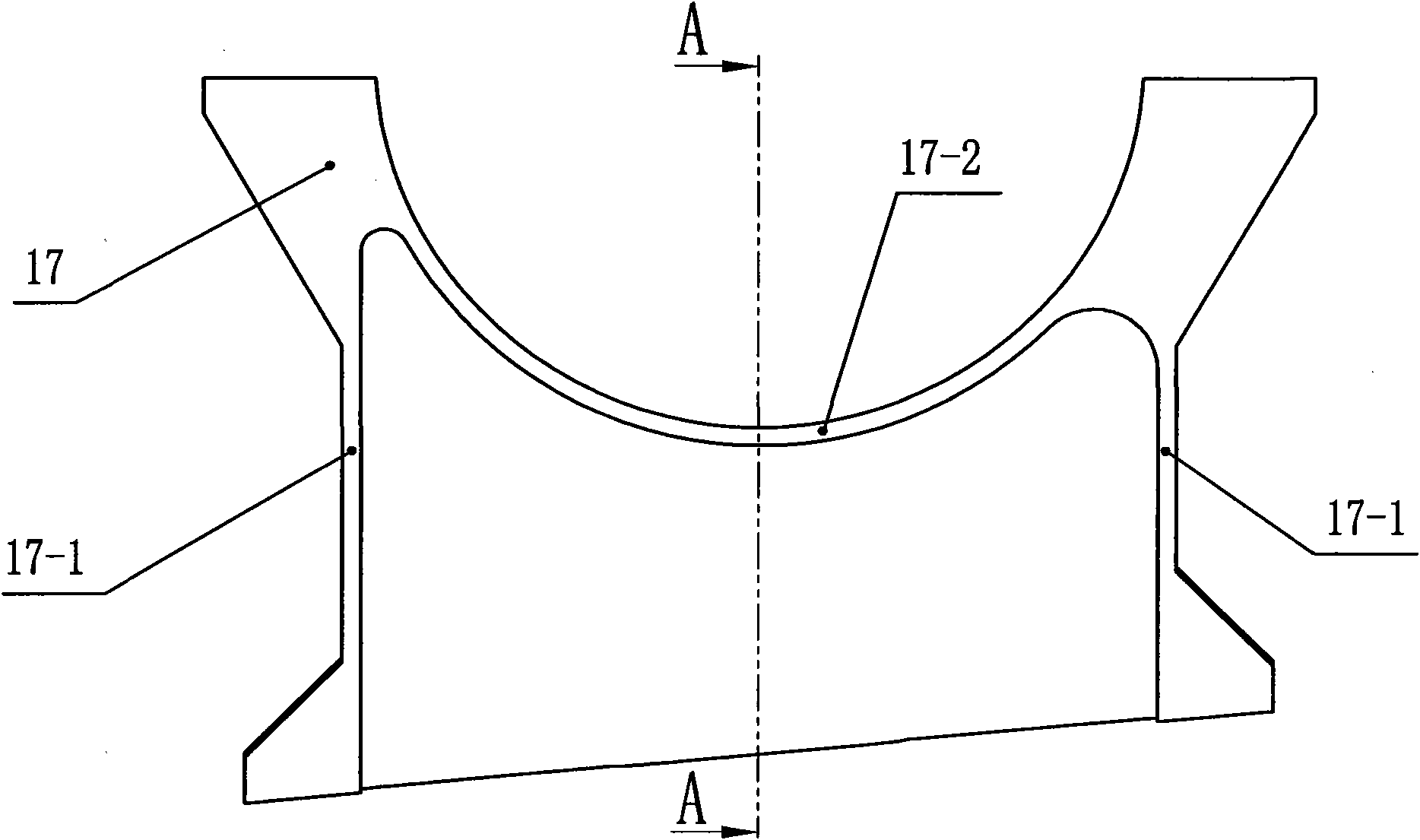

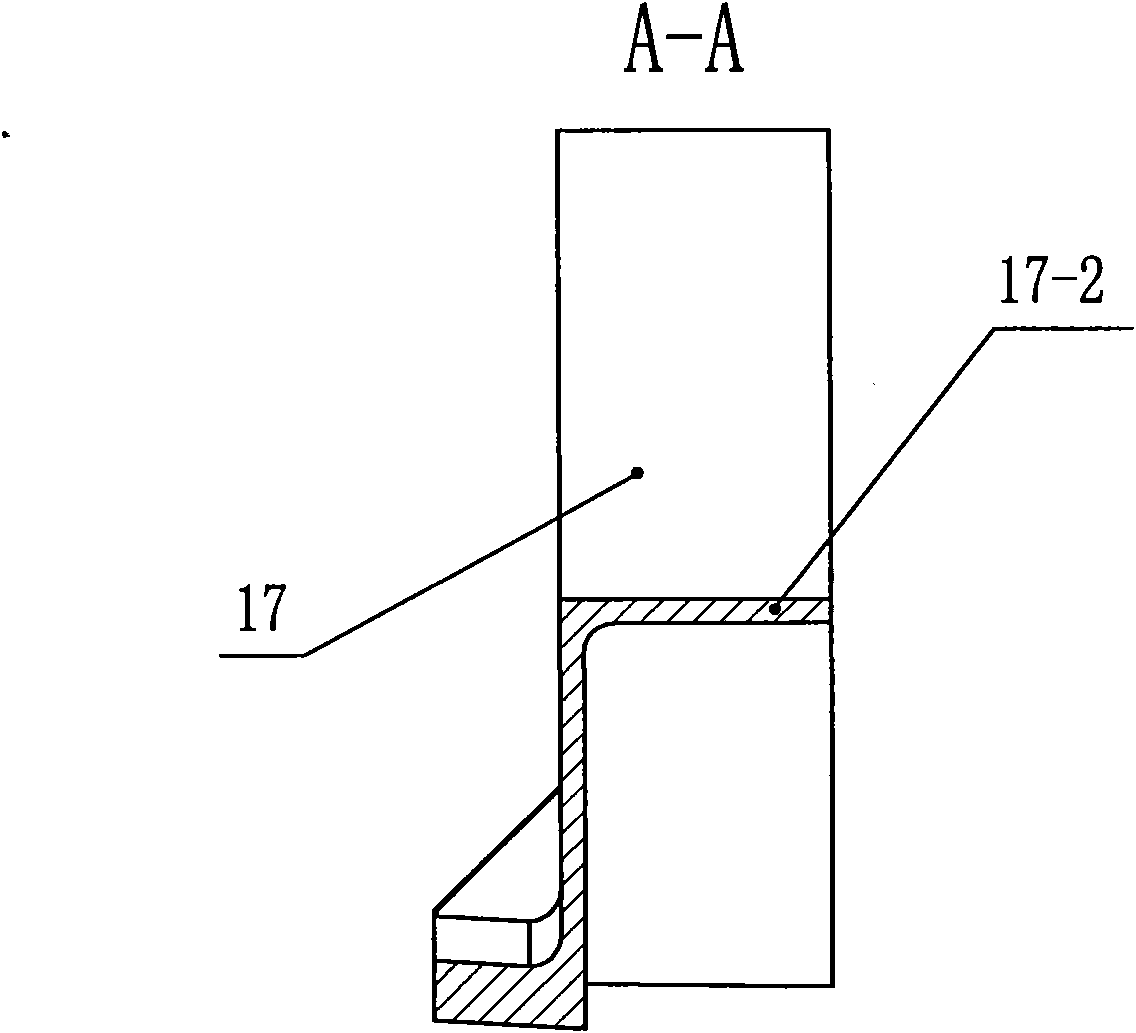

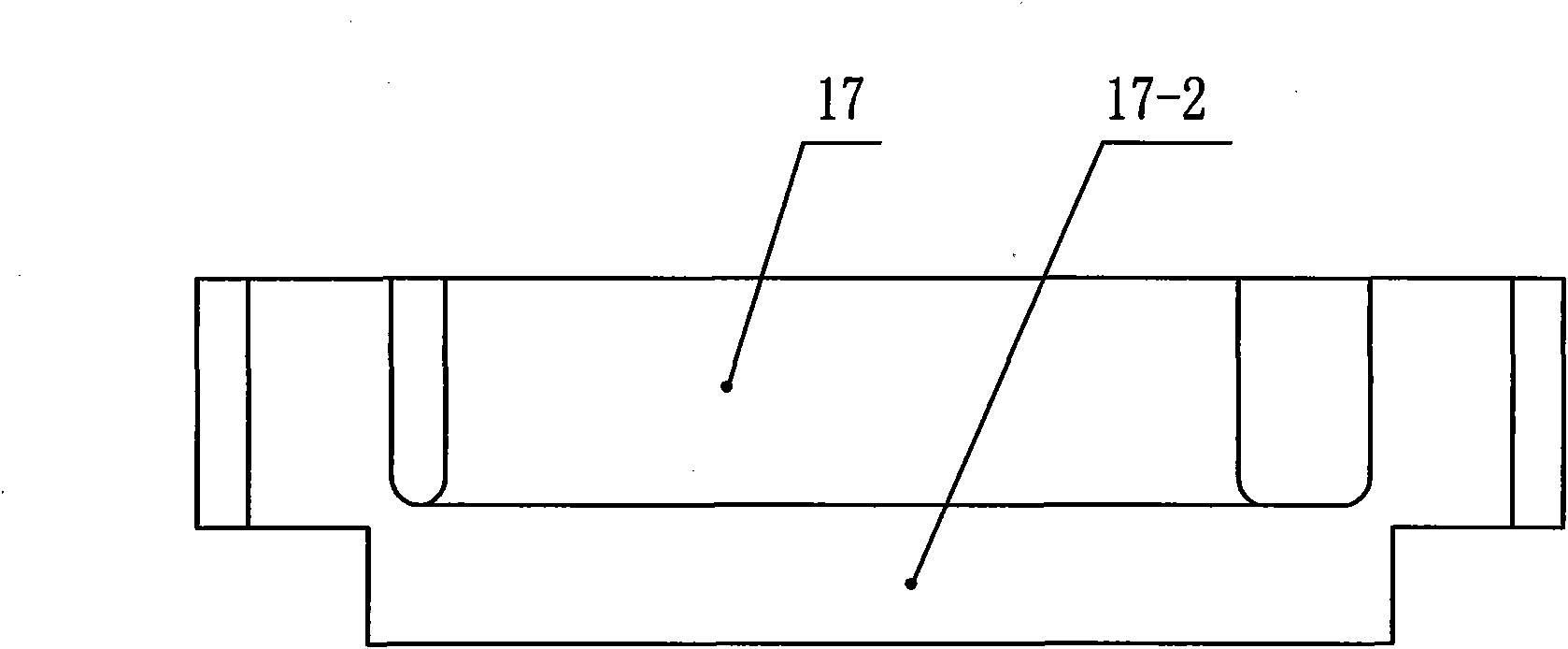

[0007] Specific implementation mode one: combine Figure 1-Figure 7 Describe this embodiment, the mold that uses the movable damping block to control the forming of asymmetric complex curved gluten forgings in this embodiment includes a thermal insulation backing plate 2, an aluminum silicate plate 4, an asbestos plate 5, a heating mold cover 6, a punch heating plate 10, Punch 13, multiple heating porcelain tubes and resistance wires 18, combined die 20, die backing plate 21, heating backing plate 22 and lower heating plate 23, the heating mold cover 6, heating backing plate 22, lower heating plate 23 and the heat insulation backing plate 2 are fixedly installed on the lower workbench 1 of the hydraulic press in sequence from top to bottom, and the combined die 20 and the die backing plate 21 are fixed and installed in the heating mold cover 6 in sequence from top to bottom. The mold 20 is provided with a flash bin 7, the punch heating plate 10 is fixedly installed on the uppe...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination Figure 4 with Figure 5 The present embodiment will be described. The aluminum silicate plate 4 of the present embodiment has a thickness of 3 mm to 7 mm. With such setting, the thermal insulation effect is better. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 4 with Figure 5 This embodiment is described, and the thickness of the asbestos board 5 of this embodiment is 20 mm - 30 mm. With such setting, the thermal insulation effect is better. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com