Gas suspension device in vapor deposition furnace

A technology of gas and suspension devices in the furnace, which is applied in the direction of gaseous chemical plating, metal material coating technology, coating, etc., can solve the problems that easily affect the normal suspension and rotation of graphite disks, affect the uniformity of gas flow, and front pore corrosion Large and other problems, to achieve the effect of improving uniformity and quality, good suspension effect, and smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

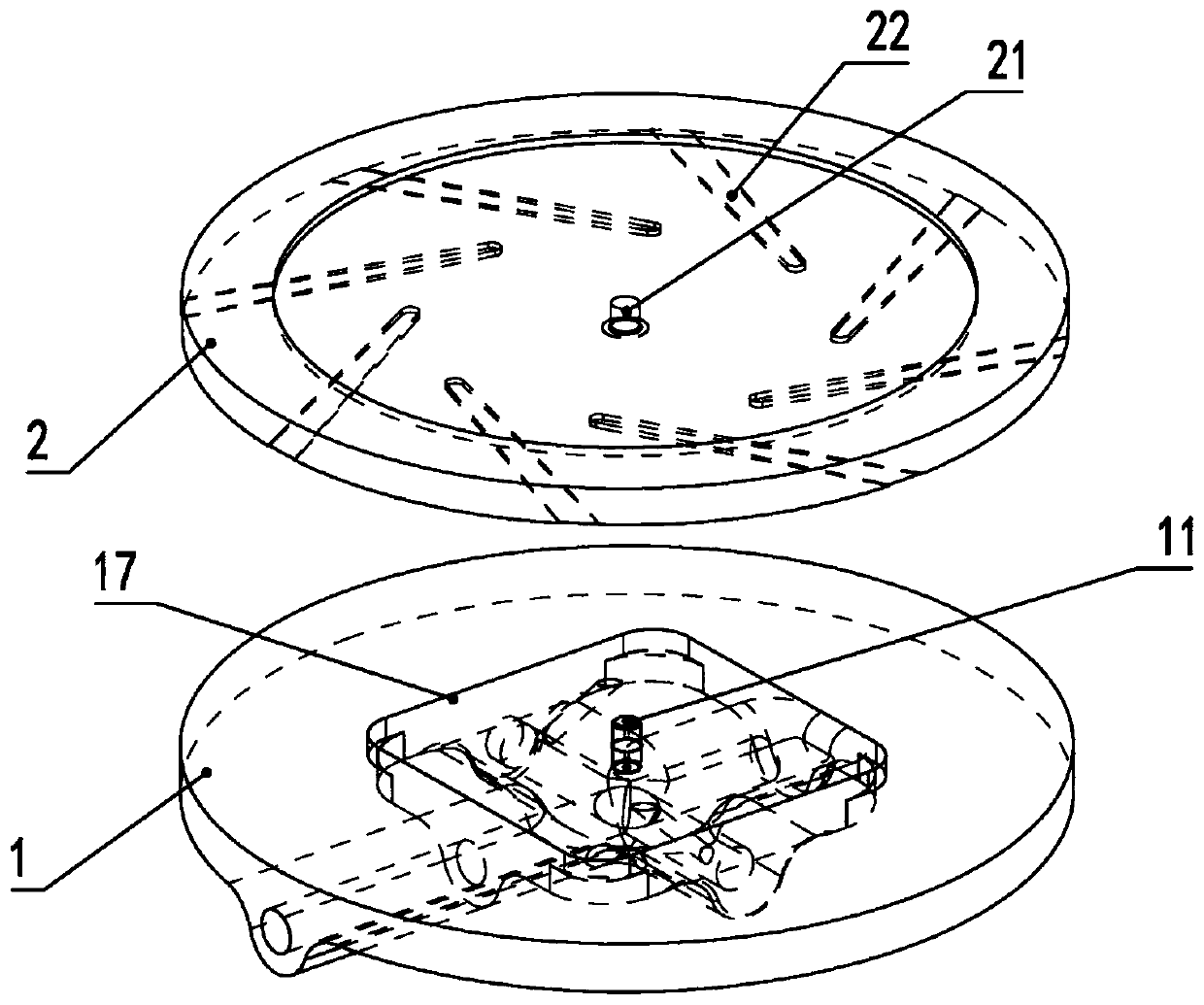

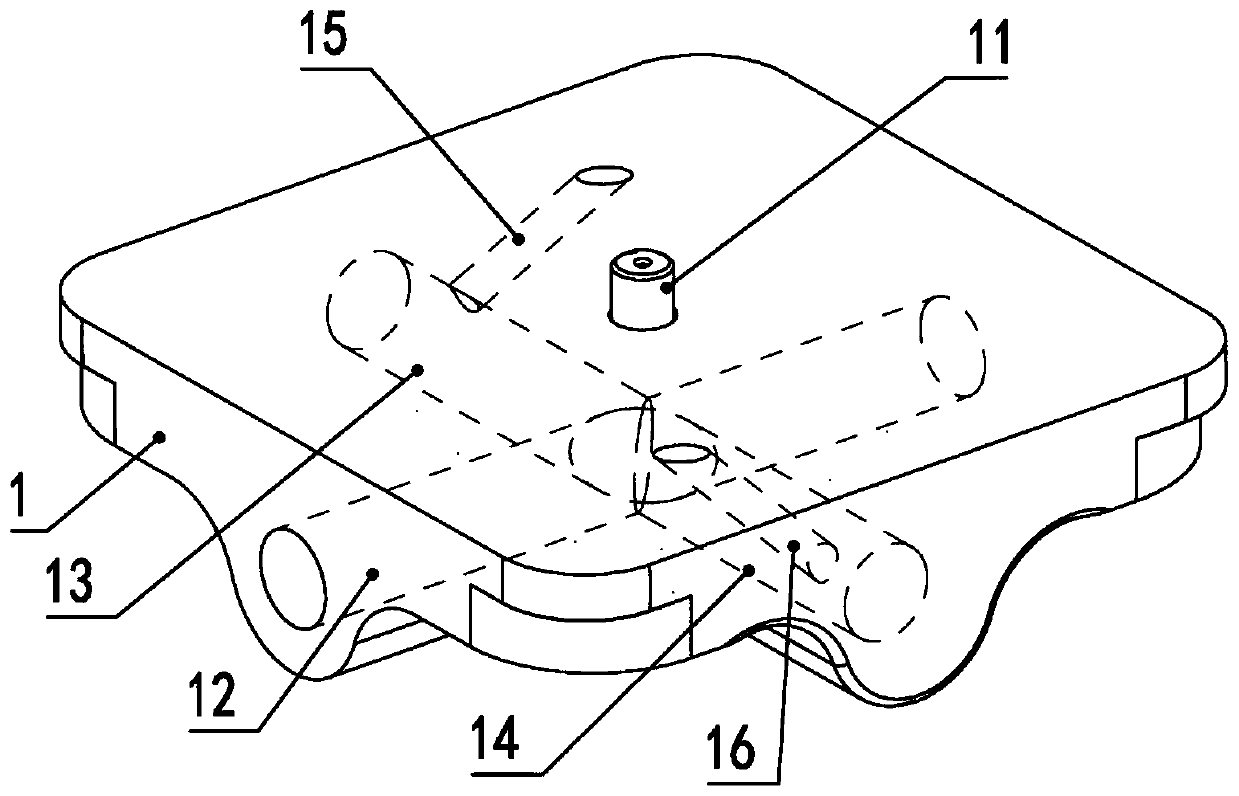

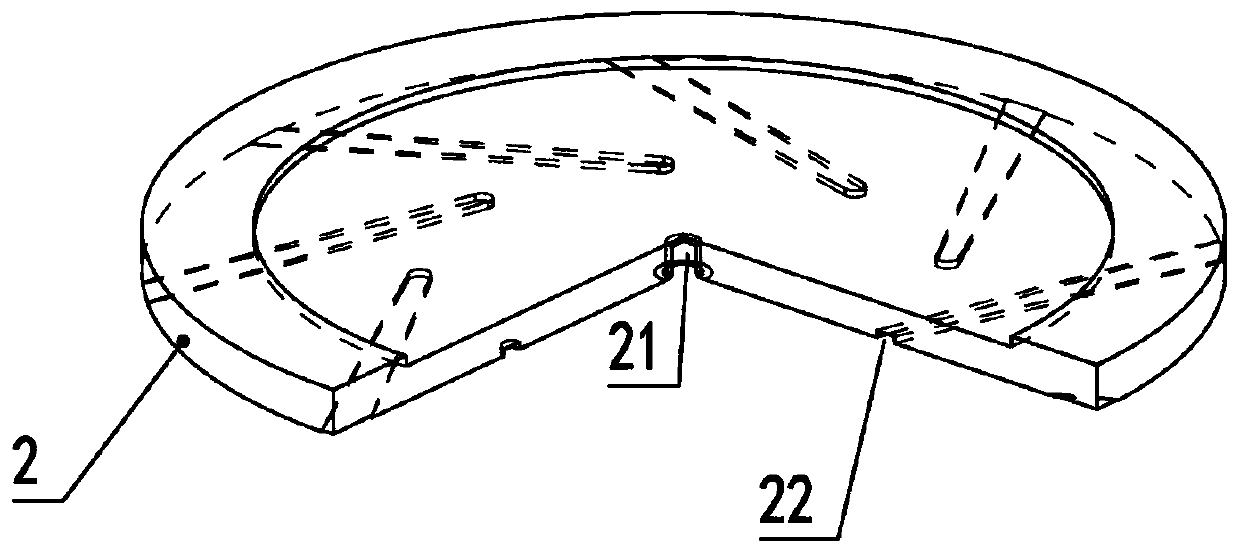

[0020] Such as Figure 1 to Figure 4 As shown, a gas suspension device in a vapor deposition furnace includes a graphite disk 2 and a base 1 arranged in parallel and rotatably matched, and the base 1 is provided with a main air inlet 12, a first gas distribution hole 13, and a second gas distribution hole 14. The first inclined air outlet hole 15 and the second inclined air outlet hole 16. The first air distribution hole 13 and the second air distribution hole 14 are respectively located on both sides of the main air inlet hole 12. The first air distribution hole 13, The second air distribution hole 14 is connected with the main air inlet hole 12 respectively at the same point, the first air distribution hole 13 is connected with the first inclined air outlet hole 15, and the second air distribution hole 14 is connected with the second ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com