Industrial flow balancing system and matching method thereof

A flow-balanced and industrial technology, applied in water supply pipeline systems, water supply installations, buildings, etc., to solve problems such as increased energy loss in the pipe network, unbalanced flow of distillation towers, and low operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

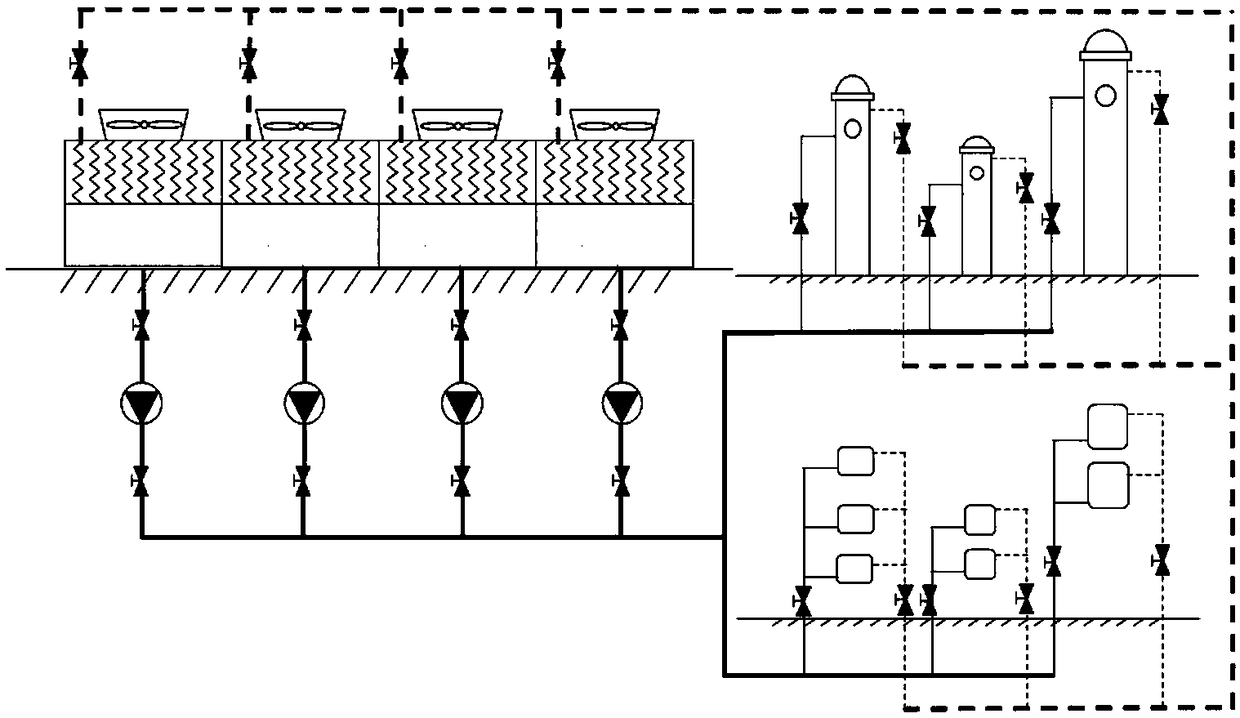

Image

Examples

Embodiment

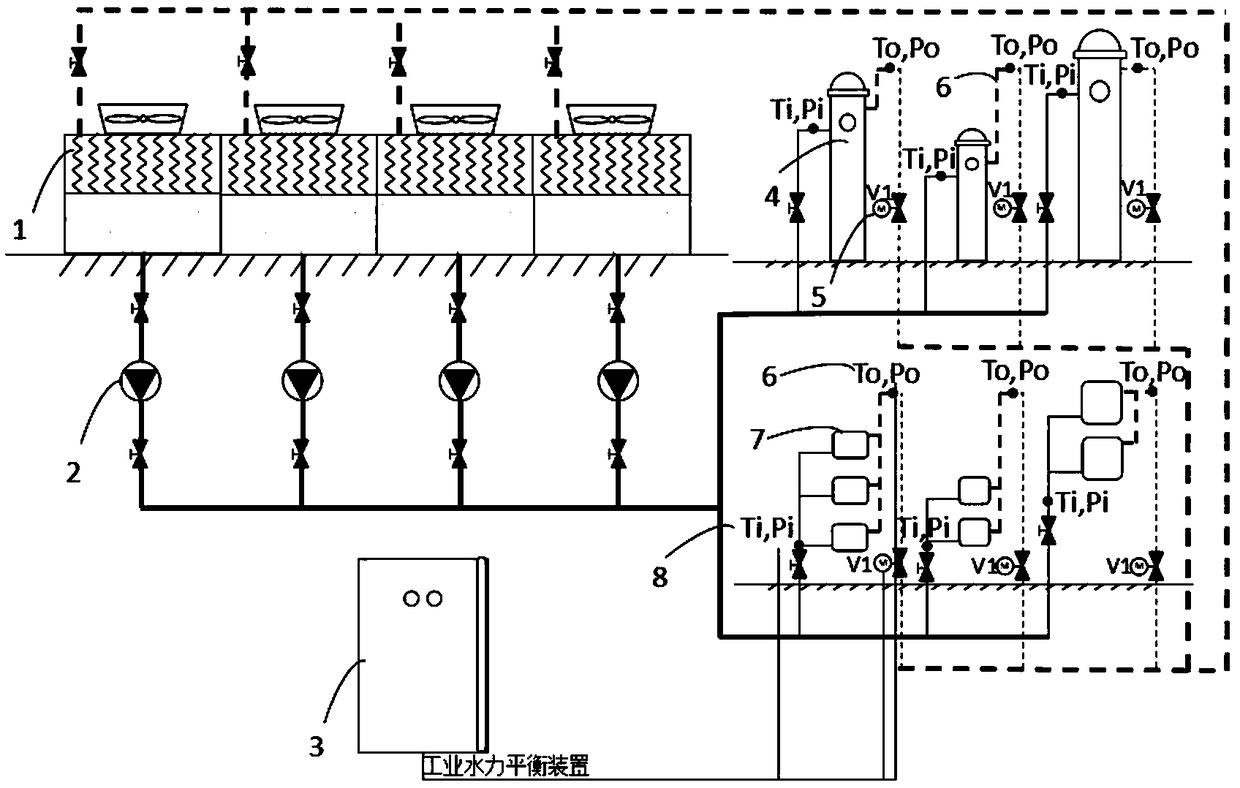

[0074] Assume that there are three rectification tower units A, B and C respectively, the height of unit A is 40 meters, and the flow requirement is 1000m 3 / h; the height of device B is 45 meters, and the flow requirement is 1200m 3 / h; the height of device C is 48 meters, and the flow requirement is 1500m 3 / h; how to design cooling water flow balance.

[0075] Implementation step 1: Set up 3 longitudinal pipelines with the same journey, the height of which shall not be less than 48 meters.

[0076] Implementation step 2: Set electric regulating valves V1 on the three longitudinal pipelines on the same journey.

[0077] Implementation step 3: Install the inlet water pressure sensor Pi and the inlet water temperature sensor Ti on the three rectification tower devices respectively, and set the outlet water pressure sensor Po and the outlet water temperature sensor To at the outlet of the rectification tower.

[0078] Implementation step 4: Install an industrial hydraulic ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com