Technique for treating pyrile cinder

A treatment process and technology for sulfuric acid residues, applied in the directions of magnetic separation, solid separation, wet separation, etc., can solve the problems of increased energy consumption, low recycling rate, reduced magnetic separation effect, etc., and achieve good economic and environmental benefits, The effect of reliable equipment operation and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

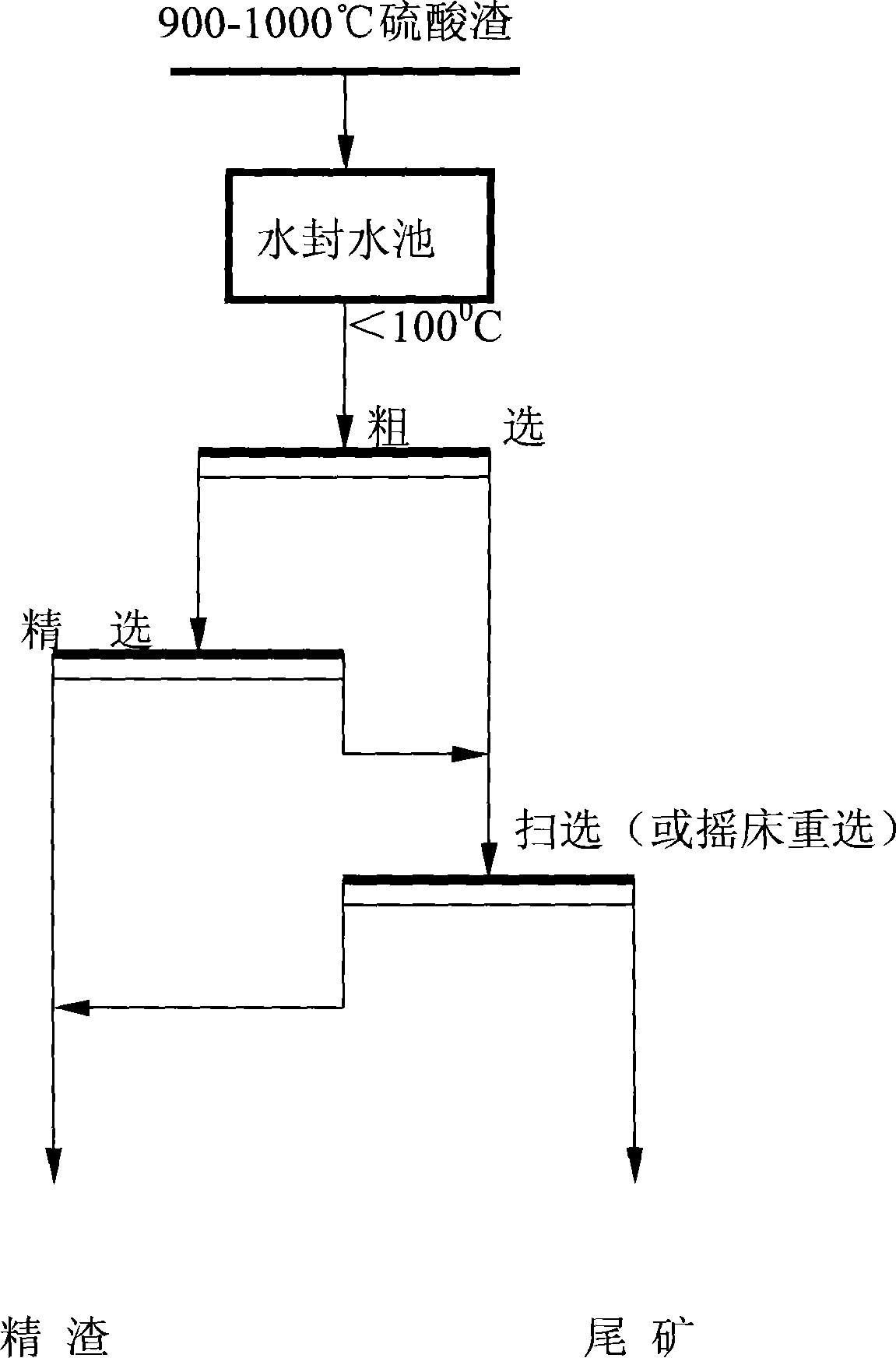

[0025] 1. The sulfuric acid slag produced in the sulfuric acid production plant from pyrite concentrate is often at a temperature between 900°C and 1000°C. At the slag outlet, a closed steel pipe is connected, and the sulfuric acid slag is directly introduced into the special water through the steel pipe. It is cooled in a water-sealed cooling pool, and the steel pipe is plunged into the water 300mm, so that the temperature is quickly reduced to below 100°C, which is actually 80°C; to prevent the iron minerals in the sulfate slag from being oxidized at high temperatures.

[0026] 2. Pump the cooled sulfuric acid slag slurry to a magnetic separator with a magnetic field strength of 1200Oc (Oersteds) for a rough magnetic separation (field strength of 1200Qc); transport the primary concentrate to the selection In the magnetic separator, a selective magnetic separation (field strength 1100Qc) is carried out. Of course, if the particle size of the sulphuric acid slag itself is too larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com