Method of comprehensive utilization of steelmaking refining precipitator dust

An alkaline and waste water technology, applied in the field of comprehensive utilization of resources, can solve problems such as acid waste water not involved in dust removal, achieve significant economic and environmental benefits, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

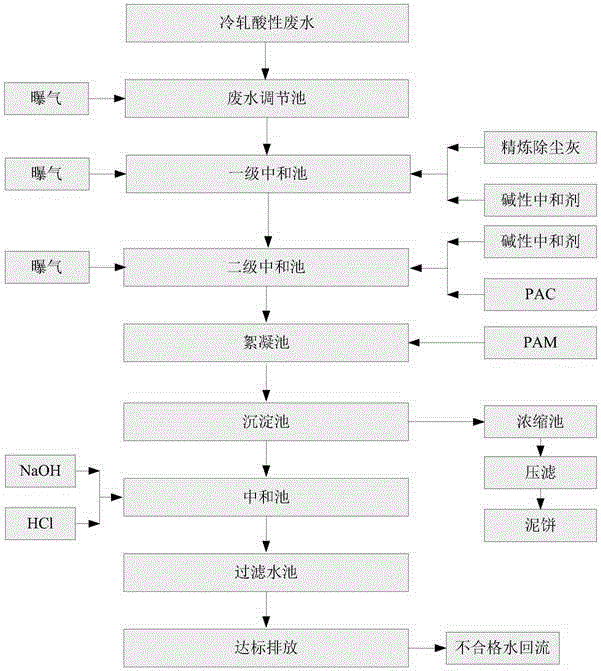

Image

Examples

Embodiment 1

[0027] The cold-rolling acid wastewater with a pH value of about 2.0 to 2.5 is treated with the steelmaking refining dust removal ash shown in Table 1. Send steelmaking refining dust to the silo of the cold-rolling acid wastewater treatment system, and the alkaline neutralizer is made into an emulsion and stored for later use; various cold-rolling acid wastewater is discharged into the regulating tank for aeration treatment, and the effluent is lifted by the The pump enters the first-level neutralization tank, and the first-level neutralization tank continues to aerate to further oxidize the ferrous ions. At the same time, 0.15% to 0.20% of the total mass of the wastewater is added to the steelmaking refining dust to adjust the pH value of the wastewater to 7.0 or so, then add 0.01% to 0.03% calcium hydroxide of the total mass of the wastewater to further control the pH value of the wastewater at 9 to 9.5;

[0028] The effluent flows to the secondary neutralization tank by its...

Embodiment 2

[0031] The cold rolling acid wastewater with a pH value of about 1.5 to 2.0 is treated with the steelmaking refining dust removal ash shown in Table 1. Send steelmaking refining dust to the silo of the cold-rolling acid wastewater treatment system, and the alkaline neutralizer is made into an emulsion and stored for later use; various cold-rolling acid wastewater is discharged into the regulating tank for aeration treatment, and the effluent is lifted by the The pump enters the first-level neutralization tank, and the aeration continues in the first-level neutralization tank to further oxidize the ferrous ions. At the same time, 0.20% to 1.0% of the total mass of the wastewater is added to the steelmaking refining dust to adjust the pH value of the wastewater to 7.0 or so, then add 0.01% to 0.03% of the total mass of the wastewater sodium hydroxide to further control the pH value of the wastewater at 9 to 9.5;

[0032] The effluent flows to the secondary neutralization tank by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com