Flue gas low-temperature combined desulfurization and denitration technology method

A technology of desulfurization, denitrification, and process method, which is applied in the field of industrial flue gas purification and treatment, can solve the problems of narrow application range of flue gas, high operating cost, and high heating energy consumption, and achieve reduced heating energy consumption and operating cost, and less infrastructure investment , the effect of high denitrification activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

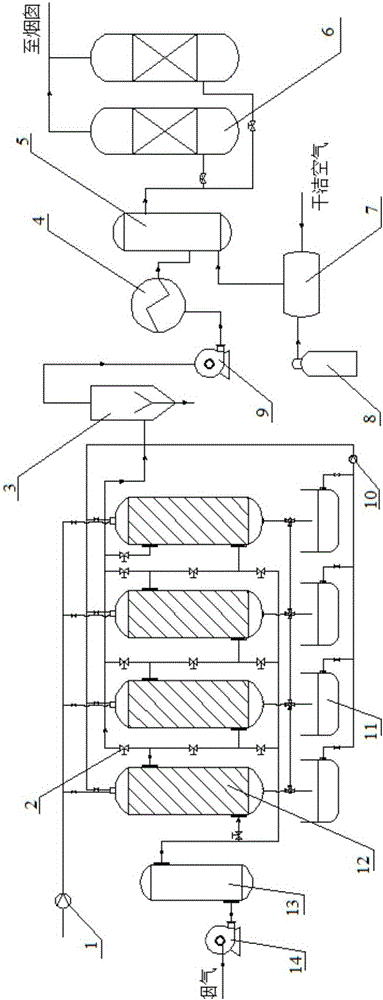

[0024] The following takes the implementation of the process of the present invention in a coking plant in Wuhai City, Inner Mongolia as an example to further illustrate the present invention, but the present invention is not therefore limited to the scope of the described embodiments. The flue gas temperature of the coking plant is about 150°C, and the moisture content of the flue gas meets the moisture requirements of the desulfurization process. It is required that the sulfur dioxide content of the exhaust gas after desulfurization and denitrification treatment is not higher than 50mg / Nm 3 , the nitrogen oxide content is not higher than 100mg / Nm3 .

[0025] The technological process of this embodiment is as figure 1 shown. The desulfurization system of this embodiment uses four desulfurization towers, and the four desulfurization towers control the flow of flue gas entering the desulfurization towers through the control butterfly valve 2 on the flue gas inlet and outlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com