Preparing method for hydrophobic ceramsite lightweight aggregate, hydrophobic ceramsite lightweight aggregate prepared with method and application of hydrophobic ceramsite lightweight aggregate

A light aggregate, hydrophobic technology, applied in the field of building materials manufacturing, to achieve good economic and environmental benefits, solve environmental pollution problems, and high hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention proposes a kind of preparation method of hydrophobic ceramsite light aggregate, which comprises the following steps:

[0042] 1) The raw materials are mixed and granulated to obtain the first granule;

[0043] 2) pre-sintering the first particles to obtain the second particles;

[0044] 3) Coating a hydrophobic functional layer on the surface of the second particle to obtain the third particle;

[0045] 4) Calcining the third particle, lowering the temperature to below 400°C, taking it out, and cooling naturally to obtain hydrophobic ceramsite light aggregate.

[0046] When preparing ceramsite, first granulate according to the batching parameters of ceramsite raw materials. In the preparation process of ceramsite in the prior art, ceramsite is calcined after being dried at a temperature below 200 degrees after granulation to make finished ceramsite. However, in the present invention, the pre-sintered particles are pre-sintered, and then the surf...

Embodiment 1

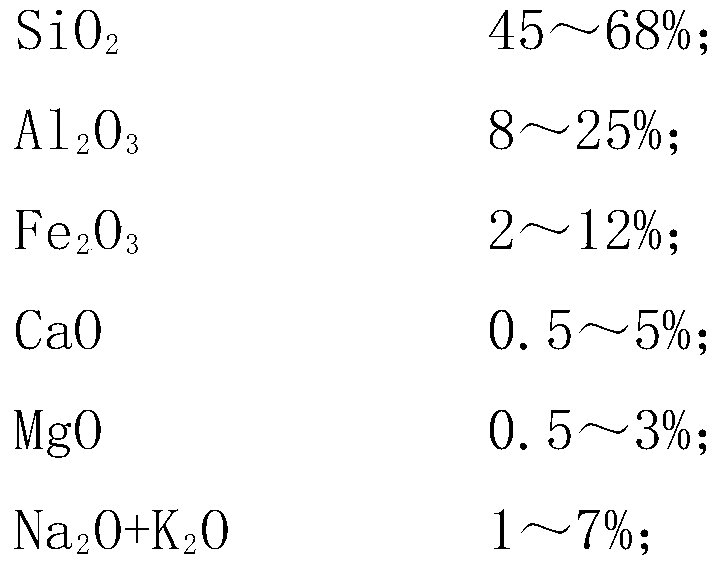

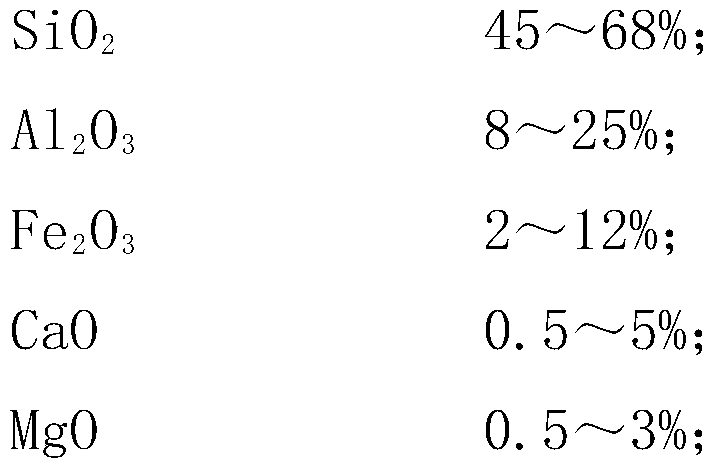

[0081] Dry, crush, grind and homogenize 45% of shale, 26% of bauxite, 18% of fly ash, 7% of attapulgite and 4% of flux respectively, and control the sieve residue of 0.045mm square hole to 1.5 % within. According to the preparation parameters of ceramsite raw materials SiO 2 53wt%, Al 2 o 3 20wt%, Fe 2 o 3 5wt%, CaO 3wt%, MgO 1wt%, Na 2 O+K 2 O 2wt% for batching to form ceramsite light aggregate powder.

[0082] Subsequently, the powder was put into a granulator and sprayed with 15% atomized water to produce spherical particles with a particle diameter of 1.5 mm. Further, the spherical particles are pre-sintered, raised from room temperature to 150°C, and kept for 60 minutes; then heated to 750°C, kept for 30 minutes, and then naturally cooled to room temperature to make pre-sintered ceramsite. Place the pre-sintered ceramsite in the dripping sieve device, and then simultaneously sink into the stearate-methyl silicon alkoxide pretreatment solution (1:1) with a mass ...

Embodiment 2

[0085] Dry, crush, grind and homogenize 46% of waste incineration ash, 25% of gasification slag, 18% of fly ash, 7% of attapulgite and 4% of flux, respectively, and control the residue on a 0.045mm square hole sieve within 1.5%. According to the preparation parameters of ceramsite raw materials SiO 2 53wt%, Al 2 o 3 20wt%, Fe 2 o 3 5wt%, CaO 3wt%, MgO 1wt%, Na 2 O+K 2 O 2wt% for batching to form ceramsite light aggregate powder.

[0086] Subsequent process is with embodiment 1.

[0087] After testing, the water absorption rate of ceramsite is 1.5% in 1h, 1.8% in 2h, 4.2% in 1d, 8.6% in 28d, the cylinder compressive strength is 4.4MPa, the bulk density is 400, and the sound absorption coefficient is 0.89.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com