Soil stabilizer prepared from phosphogypsum and desulfurized fly ash and using method thereof

A soil curing agent and desulfurization ash technology, which is applied in the field of building materials, can solve the problems of negative impact on concrete performance, poor volume stability, and unsuitable direct use, etc., achieves excellent economic and environmental benefits, saves engineering maintenance costs, and improves Effects of engineering properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

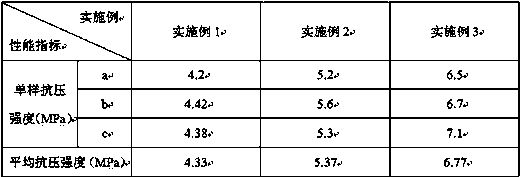

[0054] Example 1, a soil curing agent prepared by using phosphogypsum and desulfurized ash and its use method, consisting of 100 phosphogypsum, 10 desulfurized ash, 63 metakaolin, 1 lithiated bentonite, 18 calcined coal gangue powder, 7 lime, silicon Salt cement clinker 5, steel slag powder 1, diatomite 0.5, water glass 0.2, caustic soda 0.1 by mass ratio. According to the mass ratio of 10% mixed with soil, add water and stir evenly, after compaction, the performance test results are shown in Table 1.

Embodiment 2

[0055] Example 2, a soil curing agent prepared by using phosphogypsum and desulfurized ash and its use method, consisting of 100 phosphogypsum, 40 desulfurized ash, 95 metakaolin, 8 lithiated bentonite, 30 calcined coal gangue powder, 20 lime, silicon Salt cement clinker 20, steel slag powder 7, diatomite 2, water glass 3.5, caustic soda 1.5 mass ratio composition. According to the mass ratio of 7%, mixed with soil, add water and stir evenly, after compaction, performance test results are shown in Table 1.

Embodiment 3

[0056] Example 3, a soil curing agent prepared by using phosphogypsum and desulfurized ash and its use method, consisting of 100 phosphogypsum, 25 desulfurized ash, 80 metakaolin, 6 lithiated bentonite, 20 calcined coal gangue powder, 8 lime, silicon Salt cement clinker 13, steel slag powder 6, diatomite 1.3, water glass 3.0, caustic soda 1.4 by mass ratio. According to the mass ratio of 6%, mixed with soil, add water and stir evenly, after compaction, performance test results are shown in Table 1.

[0057] Table 1 Example performance test results

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com