Construction method of bagged rammed small-diameter soil-cement pile composite foundation

A technology for cement-soil piles and construction methods, which is applied in basic structure engineering, soil protection, construction, etc., can solve the problems that the treatment method cannot fully meet the requirements, the construction machinery is cumbersome to enter the site, and the depth of the pile body is too deep. Overcome uneven strength, fast construction speed, and reduce the effect of soil depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

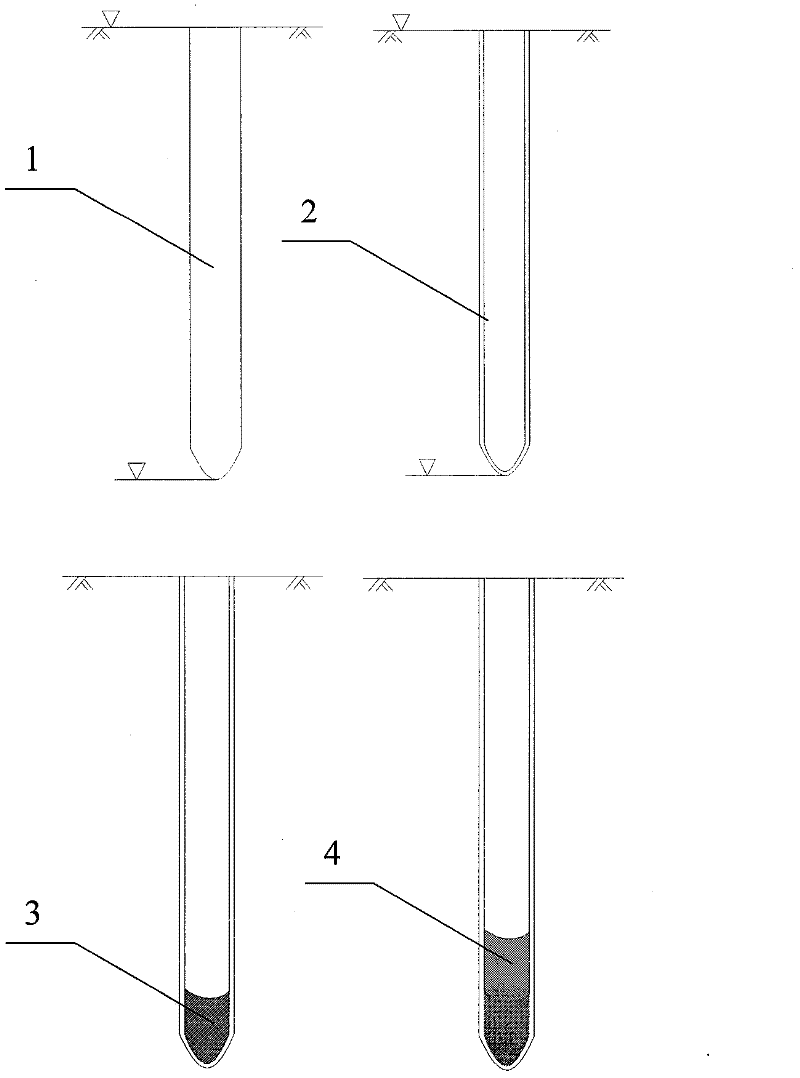

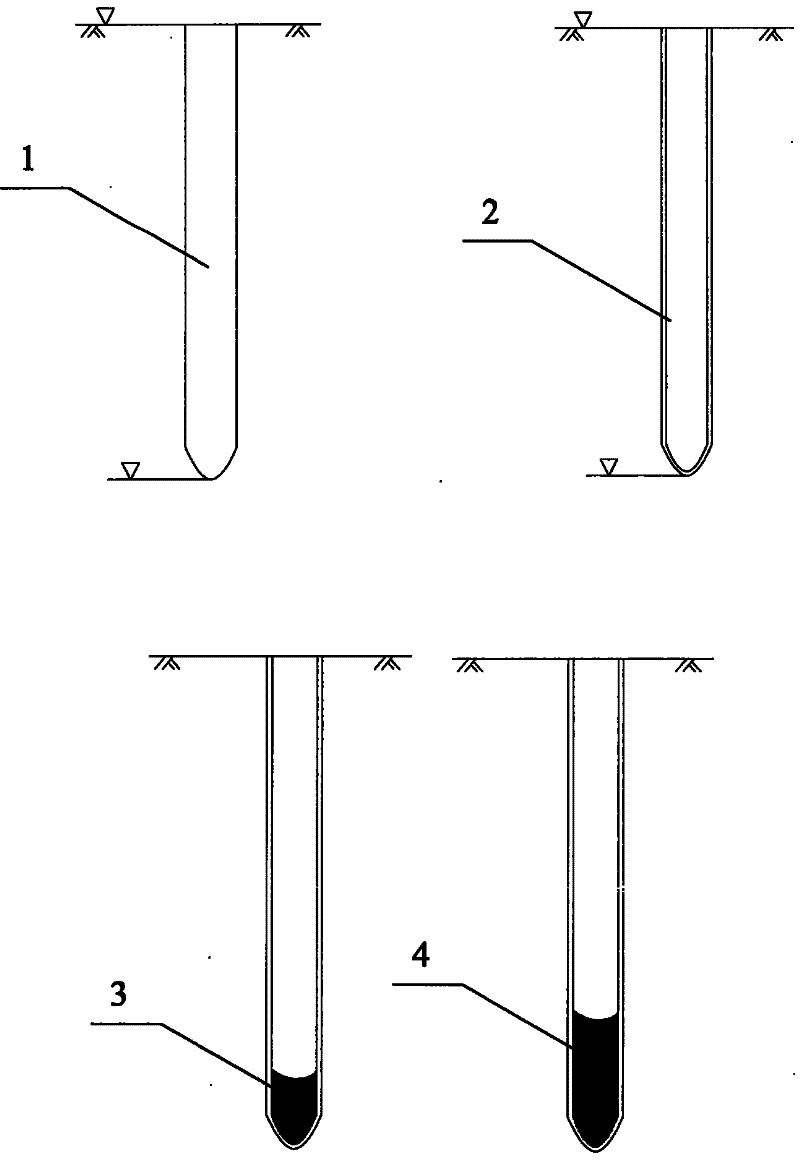

[0019] The specific construction steps of the construction method of the bagged compacted small-diameter cement-soil pile composite foundation are further described below in conjunction with the accompanying drawings:

[0020] (1) Drilling rig pre-drilling: ① According to the characteristics of the site and the form of the building, the reinforcement depth of the weak soil foundation is determined to be 7m, the pile spacing is 600mm, and the triangle is arranged; Complete the hole forming process 1 of the pile driver; ③ After the hole is formed, the drill pipe is not lifted temporarily to prevent the hole wall from shrinking and closing

[0021] (2) Geotechnical pipe bag layout: ① Make a geotechnical pipe bag with a depth of 0.5m and a length of 7.5m, and the diameter of the pipe bag is 160mm; During the bagging process, control the lowering speed of the drill pipe to 2-3m / min to prevent the drill pipe from breaking the pipe bag or causing the hole wall to collapse; Drill pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com