Shallow poor subsoil composite foundation stabilization treatment method

A technology of composite foundation and treatment method, which is applied in the field of deep soft soil layer and shallow layer composite foundation treatment, can solve the problem that the treatment method of large-scale soft foundation cannot fully meet the requirements, construction machinery is cumbersome to enter the field, and the depth of the pile body is too deep, etc. problems, to achieve the effect of fast construction speed, miniaturization of construction equipment, and reduction of post-construction settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

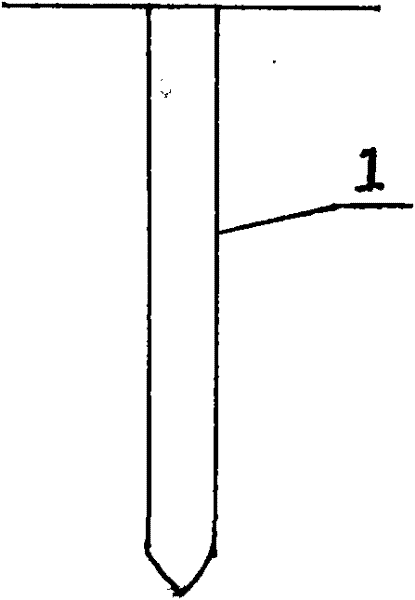

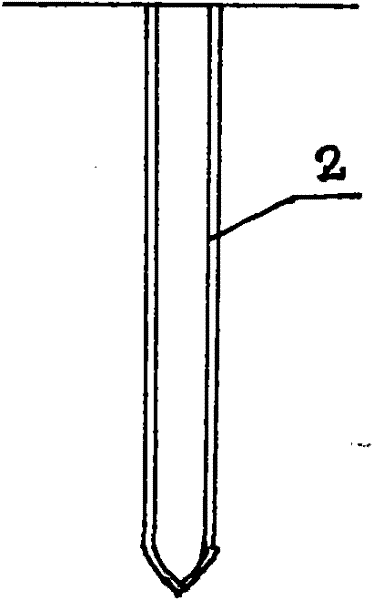

[0027] As shown in Figure 1, the geotechnical pipe bag laying steps: (1) as Figure 1a , use Luoyang shovel to form the hole, the hole forming standard: diameter Φ120mm, depth 4m, pile spacing 0.6m, triangular arrangement; (2) such as Figure 1b , Use the drill pipe to send the closed end of the geotechnical pipe bag with a diameter of 180mm and a length of 4.5m to the bottom of the hole.

[0028] The preparation steps of lime-mixed clay mixed filling material are as follows: (1) Select fresh block ash, water it for pre-digestion and pass it through a 5mm sieve; mix clay with clay excavated in situ, clay particles ≤ 15mm, remove visible organic matter cohesive soil (2) Lime and clay are mixed evenly in the mixing equipment according to the designed lime-soil ratio, and the amount of quicklime added is 8%.

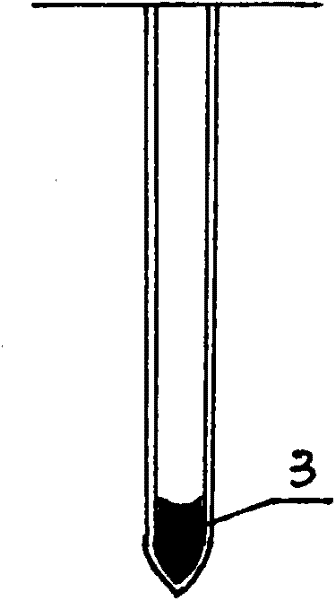

[0029] Such as Figure 1c and Figure 1d , The construction steps of compaction and compaction are: after mixing evenly, the lime soil filler is filled in layers along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com