A tidal flat soft soil reinforcement agent and preparation method thereof

A technology of reinforcing agent and soft soil, which is applied to tidal flat soft soil reinforcing agent and its preparation. The examples are related to the implementation of the present invention, which can solve the problem of permeability problems, inability of personnel and machinery to directly enter the field, poor treatment effect, etc. problems, to achieve the effect of improving the strength of the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]This embodiment provides a soft soil strengthening agent for tidal flats, which includes a main curing agent and a curing auxiliary used in conjunction.

[0031]The main curing agent in parts by weight includes: 60 parts of geopolymer slurry, 10 parts of fly ash particles, 1 part of polyvinyl alcohol, 4 parts of ethyl cellulose, 12 parts of modified lignosulfonate, and crosslinking agent 4 parts;

[0032]The curing aid includes 18 parts by weight of epoxy olefin, 6 parts of diethylene triamine, 7 parts of styrene-butadiene block copolymer, and 10 parts of potassium sodium tartrate.

[0033]The preparation method of this soft soil strengthening agent for tidal flats is:

[0034]In parts by weight, the geopolymer slurry and fly ash particles are mixed and stirred for 50 seconds to obtain a mixed matrix; the polyvinyl alcohol and ethyl cellulose are dissolved in water and mixed with the crosslinking agent at 120°C for 60 minutes. , Cooling to 80°C, adding lignosulfonate and mixed matrix, and...

Embodiment 2

[0038]This embodiment provides a soft soil strengthening agent for tidal flats, which includes a main curing agent and a curing auxiliary used in conjunction.

[0039]The main curing agent in parts by weight includes: 40 parts of geopolymer slurry, 5 parts of fly ash particles, 3 parts of polyvinyl alcohol, 2 parts of ethyl cellulose, 8 parts of modified lignosulfonate, crosslinking agent 7 copies;

[0040]The curing aid includes 12 parts by weight of epoxy olefin, 4 parts of diethylene triamine, 9 parts of styrene-butadiene block copolymer, and 7 parts of potassium sodium tartrate.

[0041]The preparation method of this soft soil strengthening agent for tidal flats is:

[0042]According to parts by weight, the geopolymer slurry and fly ash particles are mixed and stirred for 40 seconds to obtain a mixed matrix; polyvinyl alcohol and ethyl cellulose are dissolved in water, and mixed and reacted with the crosslinking agent at 140°C for 40 minutes , Cooling down to 70℃, adding lignosulfonate and ...

Embodiment 3

[0046]This embodiment provides a soft soil strengthening agent for tidal flats, which includes a main curing agent and a curing auxiliary used in conjunction.

[0047]The main curing agent in parts by weight includes: 48 parts of geopolymer slurry, 7 parts of fly ash particles, 3 parts of polyvinyl alcohol, 3 parts of ethyl cellulose, 11 parts of modified lignosulfonate, and crosslinking agent 5 copies;

[0048]The curing aid includes 14 parts by weight of epoxy olefin, 5 parts of diethylene triamine, 8 parts of styrene-butadiene block copolymer, and 9 parts of potassium sodium tartrate.

[0049]The preparation method of this soft soil strengthening agent for tidal flats is:

[0050]In parts by weight, mix and stir the geopolymer slurry and fly ash particles for 43 seconds to obtain a mixed matrix; dissolve polyvinyl alcohol and ethyl cellulose in water, and mix and react with the crosslinking agent at 128°C for 48 minutes , Cooling to 77°C, adding lignosulfonate and mixed matrix, reacting for ...

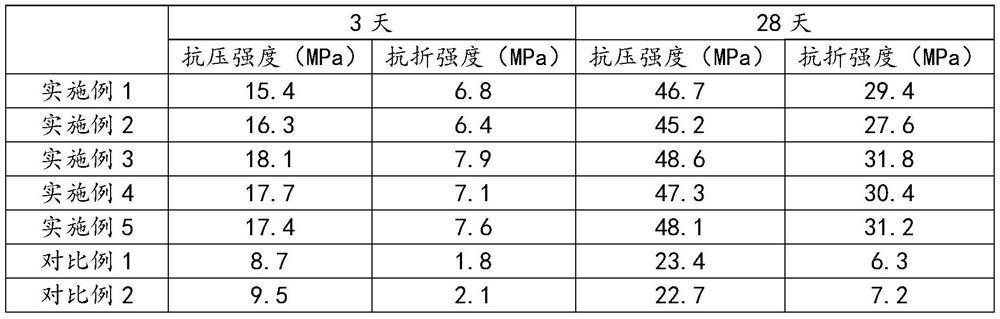

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com